Textile Printer Applications

Digital Textile Printer Application Options

Home Textile Printer

Digital Home Textile Printers | Curtain Printers | Bedding Printers

MT Provides Various Of Digital Home Textile Printers. Check Them Now!

| Model | MT-Belt R8 |

|---|---|

| Application | Suits for both elastic and non-elastic fabric printing. |

| Printhead | Ricoh Gen5/Gen6 |

| Print width | 1800mm(70.8'') |

| Colors | CMYK |

Fabric Material Printer

Fabric Types Apply to Digital Textile Printer | Fabric Printing Machine

MT digital printing machine can print almost all fabrics and is the best choice for fabric printing.

| Model | MT-Belt 13200PLUS |

|---|---|

| Application | Suits for both elastic and non-elastic fabric printing. |

| Printhead | Epson i3200 |

| Print width | 1800mm(70.8'') |

| Colors | CMYK |

Fashion Textile And Apparel Printer

Digital Garment Printers | Apparel Printing Machines

Neon Printing, Fluorescence Printing, Garment Printing, Fashion Printing!!!

| Model | MT-P1908A1 |

|---|---|

| Application | Suitable for printing on various clothing fabrics. |

| Printhead | 8pcs Epson i3200 |

| Print width | 1900mm(74.80”) |

| Colors | CMYK+Fluorescent color |

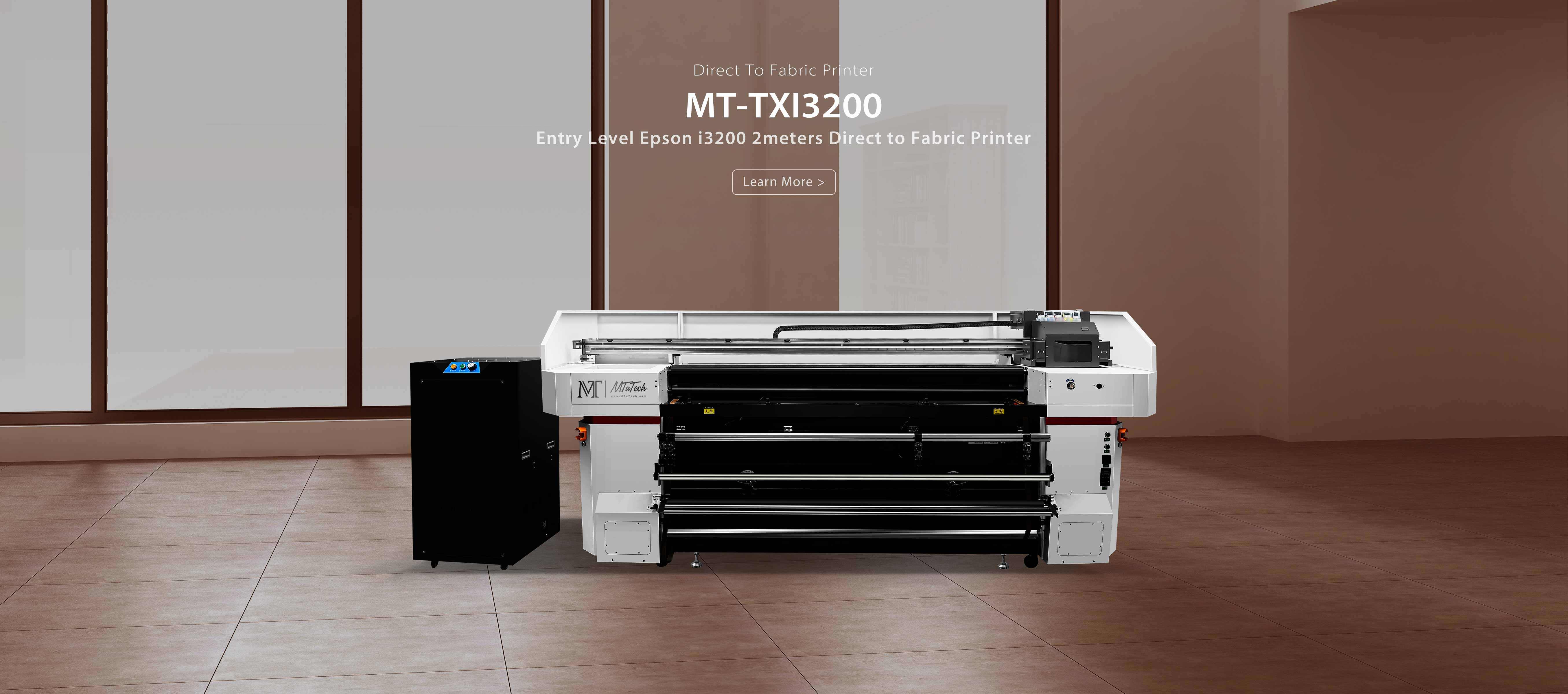

Soft Signages Printer

Digital Flag Printers | Digital Textile Flag Printers

New Advertising Form, Printing By Digital Textile Flags Printer!

| Model | MT-TXI3200 |

|---|---|

| Application | Suits for soft signage, home textile and fashion apparel printing. |

| Printhead | Epson i3200 |

| Print width | 2000mm (78.74'') |

| Colors | CMYK + LLmLyLk |

|

MT-Belt R8

|

MT-Belt 13200PLUS

|

MT-P1908A1

|

MT-TXI3200

|

|

Suits for both elastic and non-elastic fabric printing.

|

Suits for both elastic and non-elastic fabric printing.

|

Suitable for printing on various clothing fabrics.

|

Suits for soft signage, home textile and fashion apparel printing.

|

|

Ricoh Gen5/Gen6

|

Epson i3200

|

8pcs Epson i3200

|

Epson i3200

|

|

1800mm(70.8'')

|

1800mm(70.8'')

|

1900mm(74.80”)

|

2000mm (78.74'')

|

|

CMYK

|

CMYK

|

CMYK+Fluorescent color

|

CMYK + LLmLyLk

|

Model |

|---|

Application |

Printhead |

Print width |

Colors |