DTF Printer Tension Systems Explained

Direct to Film (DTF) printing has rapidly become one of the most preferred garment decoration technologies due to its flexibility, color vibrancy, and ability to print on a wide range of fabrics. From small print shops to large-scale apparel manufacturers, DTF printing offers an efficient solution for high-quality textile printing. However, while much attention is given to inks, print heads, and curing processes, one critical component often overlooked is the tension system.

The tension system plays a foundational role in ensuring smooth film movement, accurate printing, and consistent output. Even the most advanced DTF printer can produce poor results if the tension system is unstable or improperly calibrated. This article provides a deep, practical understanding of DTF printer tension systems, their types, working principles, challenges, maintenance practices, and how they directly impact print quality and production efficiency.

By the end of this guide, you will clearly understand why tension systems are essential and how optimizing them can significantly improve your DTF printing workflow.

Understanding DTF Printing Technology

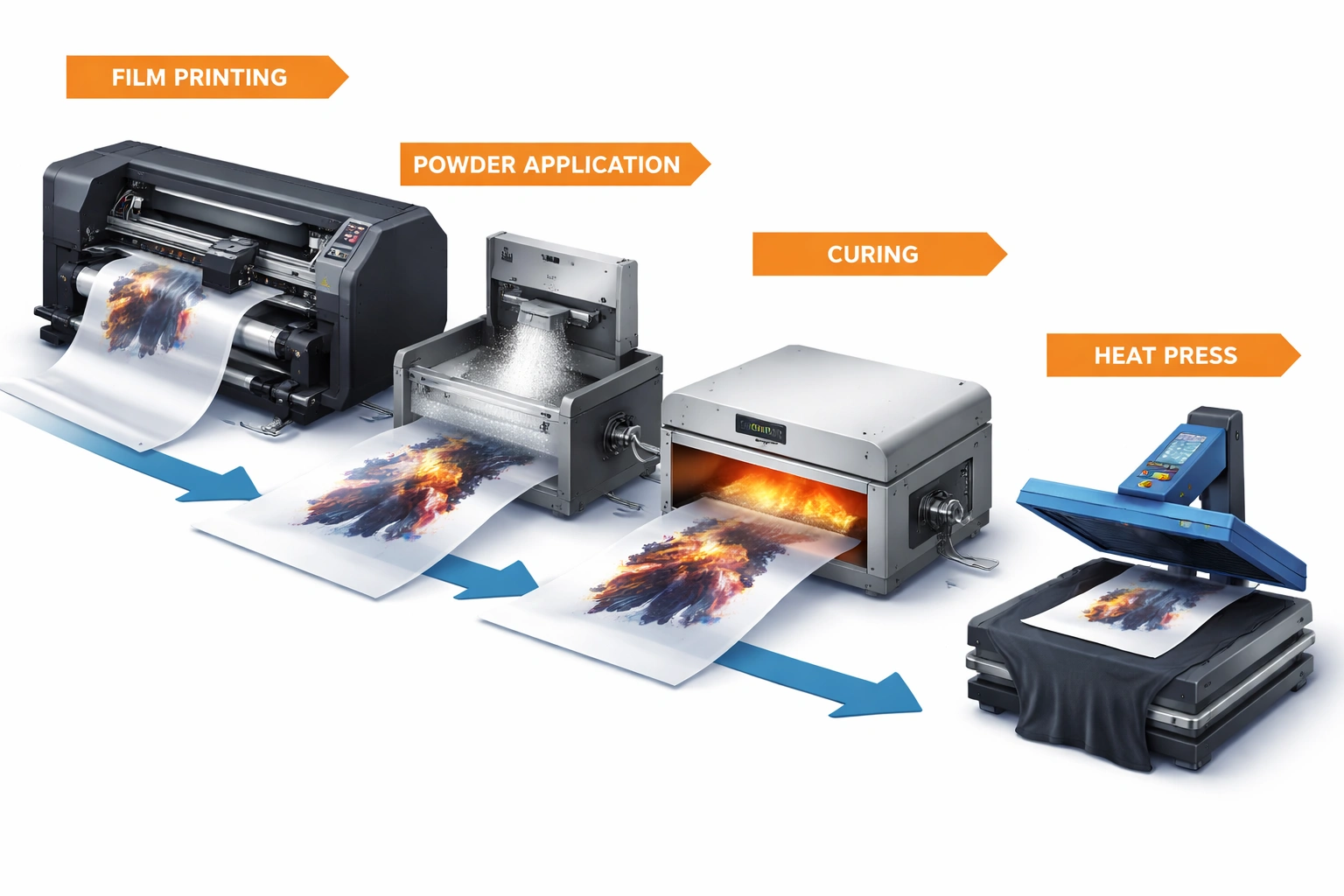

DTF printing is a digital transfer process where designs are printed onto a specially coated film instead of directly onto fabric. After printing, adhesive powder is applied, cured, and then heat-pressed onto garments. This method allows printers to work with cotton, polyester, blends, nylon, and even dark fabrics without pretreatment.

The accuracy of this entire process depends heavily on controlled film movement. The film must pass through the printer smoothly, evenly, and without distortion. This is where the tension system becomes indispensable.

Unlike paper printing, DTF films are thin, flexible, and sensitive to stretching or wrinkling. Any fluctuation in film tension can result in registration errors, ink spread, banding, or inconsistent adhesive application.

What Is a Tension System in a DTF Printer?

A tension system is a mechanical or electronic mechanism designed to regulate the amount of force applied to the DTF film as it moves through the printer. Its primary purpose is to maintain a stable, uniform tension level from the film supply roll to the take-up reel.

In simple terms, the tension system ensures that:

The film does not sag or slack

The film does not stretch or deform

The film remains flat and aligned during printing

The print head maintains a consistent distance from the film surface

Without proper tension control, the film feed becomes unpredictable, leading to quality defects and production downtime.

Why Tension Control Is Critical in DTF Printing

1. Film Stability During Printing

Stable film movement is essential for accurate ink placement. If the film shifts or vibrates while printing, the result can be blurred graphics or uneven ink layers. A properly tuned tension system keeps the film steady and flat throughout the printing cycle.

2. Consistent Print Registration

DTF designs often involve multiple passes of white and color inks. Any misalignment caused by inconsistent tension can lead to ghosting, color overlap errors, or halo effects around the design.

3. Protection of Print Heads

Uneven tension can cause the film to rise unexpectedly, increasing the risk of head strikes. Print head damage is one of the costliest issues in DTF printing, and proper tension control significantly reduces this risk.

4. Reduced Material Waste

Film misfeeds, wrinkles, and skewing often result in failed prints. By maintaining consistent tension, businesses can reduce wasted film, ink, powder, and labor.

5. Improved Production Speed

When tension is stable, printers can operate at higher speeds without compromising quality. This improves overall productivity and order turnaround time.

How DTF Printer Tension Systems Work

A typical DTF tension system works by balancing resistance between the film supply roll and the take-up mechanism. The system continuously compensates for changes in roll diameter, film weight, and printing speed.

Key components include:

Supply shaft or film holder

Tension rollers or dancer bars

Sensors or mechanical springs

Motors or pneumatic regulators

Take-up reel system

As the film unwinds, the tension system adjusts resistance to ensure uniform pressure regardless of how much film remains on the roll.

Types of Tension Systems Used in DTF Printers

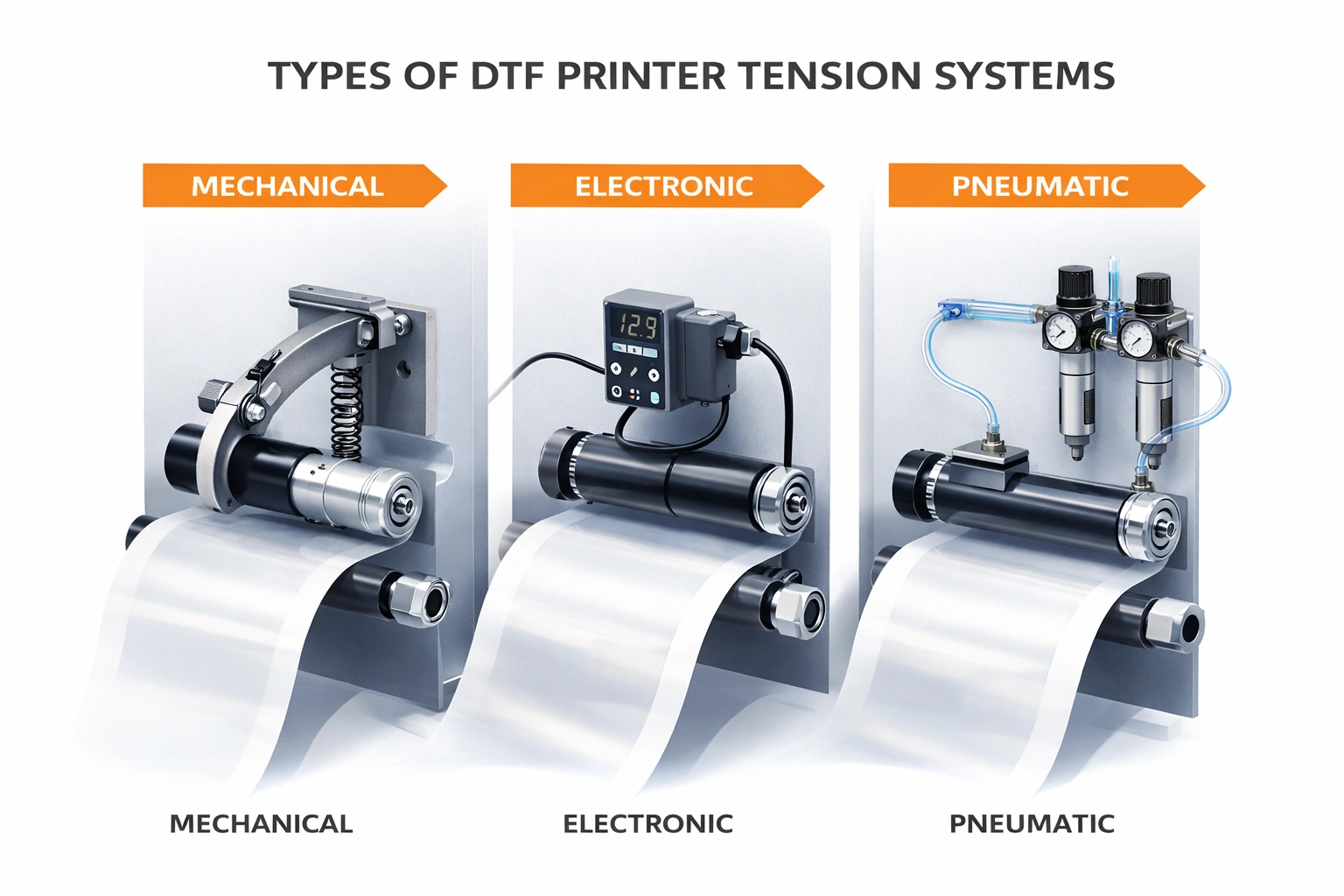

Mechanical Tension Systems

Mechanical tension systems rely on springs, weighted arms, or friction-based components to regulate film tension. These systems are commonly found in entry-level and mid-range DTF printers.

Advantages:

Simple design

Low cost

Easy to repair

Limitations:

Manual adjustment required

Less precise under variable speeds

Performance can degrade over time due to wear

Mechanical systems are best suited for small operations with consistent media usage.

Electronic Tension Control Systems

Electronic tension systems use sensors, servo motors, and control boards to automatically adjust film tension in real time. These systems are typically found in professional and industrial-grade DTF printers.

Advantages:

High precision

Automatic adjustment

Stable performance at high speeds

Limitations:

Higher cost

Requires skilled maintenance

More complex troubleshooting

Electronic systems are ideal for high-volume production environments where consistency and speed are critical.

Pneumatic Tension Systems

Pneumatic tension systems use controlled air pressure to regulate film tension. These systems respond quickly to tension changes and are highly sensitive.

Advantages:

Smooth and responsive control

Suitable for delicate films

Consistent tension under varying conditions

Limitations:

Requires air supply

More expensive setup

Needs regular air system maintenance

Pneumatic systems are often used in advanced industrial printing setups.

Key Features to Look for in a DTF Tension System

Adjustability

An effective tension system should allow easy adjustment based on film thickness, width, and printing speed. Whether manual or automatic, fine-tuning capability is essential.

Real-Time Feedback

Advanced systems include sensors that monitor tension continuously and make instant corrections. This prevents sudden changes that could affect print quality.

Material Compatibility

The tension system should work efficiently with various DTF film types, including matte, glossy, hot peel, and cold peel films.

Build Quality

Durable rollers, bearings, and guides reduce vibration and ensure long-term reliability.

Common Tension-Related Problems in DTF Printing

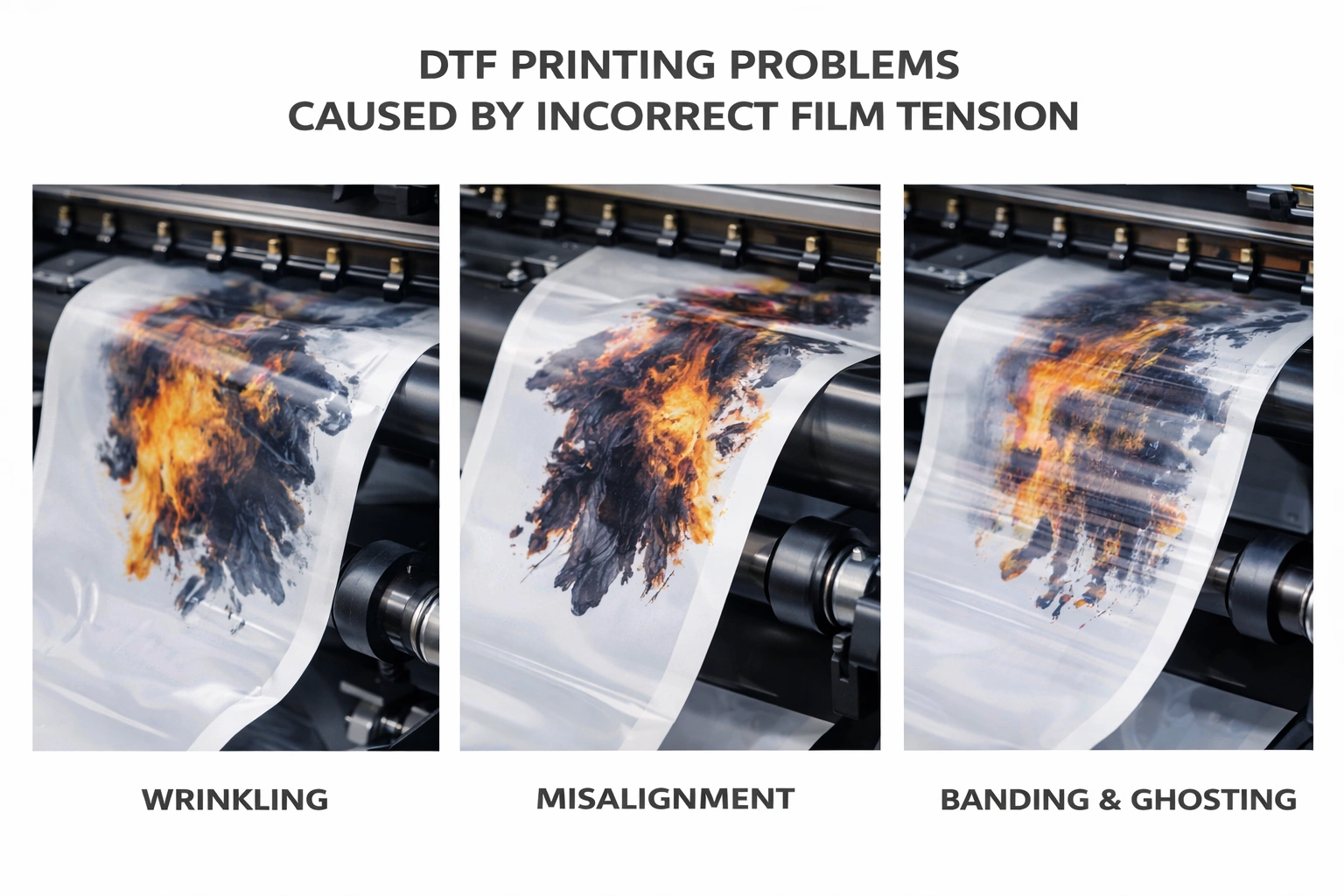

Wrinkled or Skewed Film

This usually indicates insufficient or uneven tension. It can cause distorted prints and poor adhesive bonding.

Banding or Ghosting

Inconsistent film movement can lead to irregular ink deposition, resulting in visible lines or double images.

Film Slippage

Excessively low tension may cause the film to slip during printing, affecting design placement accuracy.

Excessive Film Stretching

Over-tensioning can stretch the film, leading to size distortion and registration errors during heat transfer.

How to Optimize Tension Settings

Start with manufacturer-recommended settings

Adjust gradually, not abruptly

Test with small prints before full production

Monitor film behavior during printing

Recheck settings when changing film rolls

Consistency is more important than tightness. The goal is smooth, controlled movement—not maximum tension.

Maintenance Practices for Long-Term Performance

Regular maintenance ensures that the tension system continues to operate efficiently:

Clean rollers and guides weekly

Inspect springs, belts, and sensors

Lubricate moving parts if required

Replace worn components promptly

Calibrate electronic systems periodically

Preventive maintenance minimizes downtime and extends equipment life.

Choosing the Right DTF Printer Based on Tension System

When investing in a DTF printer, evaluate:

Production volume requirements

Types of films you plan to use

Available technical support

Ease of tension adjustment

Long-term maintenance costs

A reliable tension system may increase upfront cost but delivers better consistency and lower operating expenses over time.

Future Trends in DTF Tension Technology

As DTF printing continues to evolve, tension systems are becoming smarter and more automated. Emerging trends include:

AI-based tension optimization

Self-calibrating systems

Integration with print management software

Predictive maintenance alerts

These advancements aim to further reduce human error and maximize productivity.

Conclusion

Tension systems are a critical yet often underestimated component of DTF printers. They directly influence print quality, production efficiency, material usage, and equipment longevity. Whether mechanical, electronic, or pneumatic, a well-designed tension system ensures smooth film feeding and consistent results.

By understanding how tension systems work and maintaining them properly, print businesses can significantly enhance output quality while reducing waste and downtime. Investing time and attention in tension optimization is not optional—it is essential for long-term success in DTF printing.explore our high-quality DTF printers here

Frequently Asked Questions

What is the main function of a tension system in a DTF printer?

Its primary function is to maintain stable and consistent film movement during printing, ensuring accurate ink placement and high-quality output.

How often should tension settings be adjusted?

Adjustments should be made whenever film type, thickness, or width changes, and periodic checks should be performed during regular maintenance.

Can poor tension damage a DTF printer?

Yes, improper tension can lead to print head strikes, misfeeds, and mechanical stress, resulting in costly repairs.

Are automatic tension systems worth the investment?

For high-volume or professional printing operations, automatic systems offer better consistency, reduced errors, and improved productivity.

What signs indicate tension system problems?

Wrinkled film, ghosting, banding, skewed prints, and unusual noises are common indicators of tension-related issues.