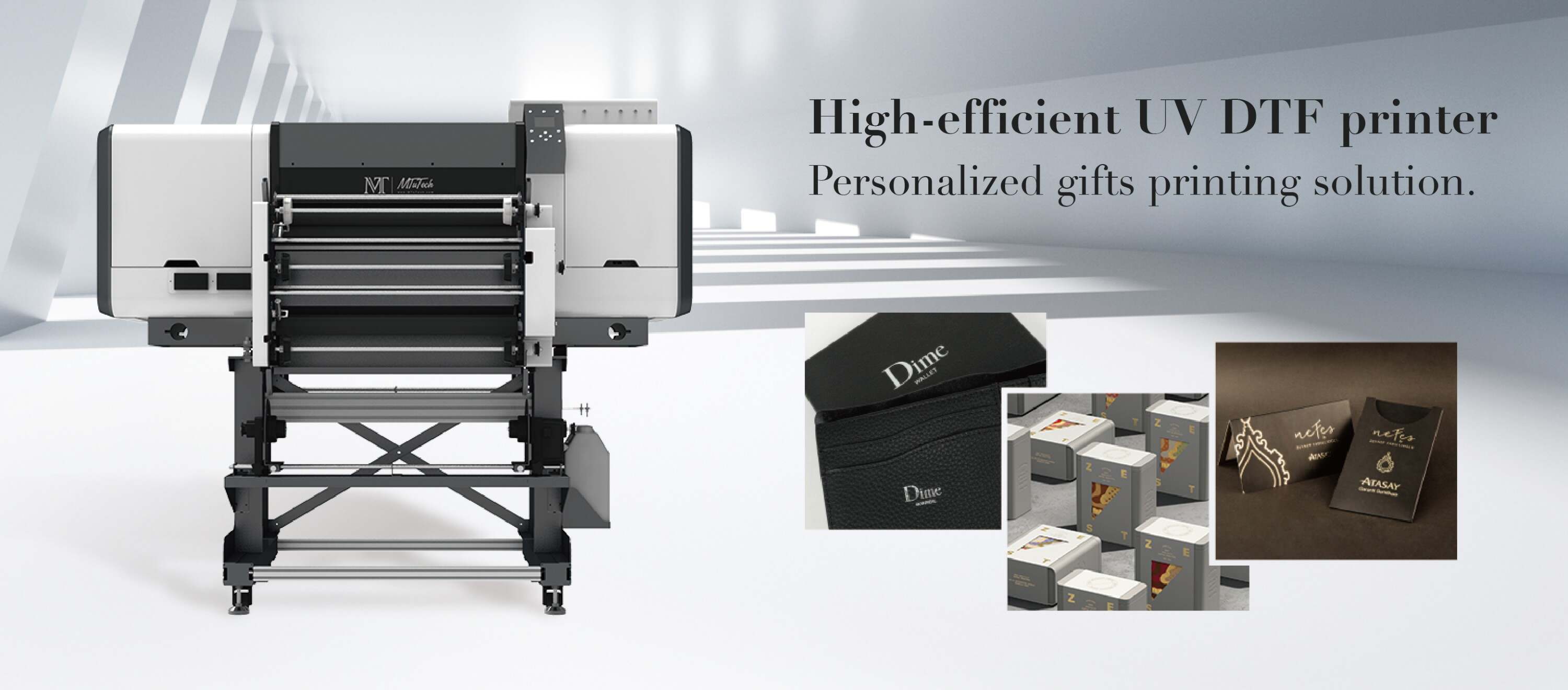

UV DTF Printer

UV DTF Printer Options

Epson i1600 60cm | Max Printing Speed 8m/h

UV DTF Printer MT-UV DTF 60

Cutting-edge UV DTF printing solution.

| Model Number | MT -UV DTF 60 |

|---|---|

| Printhead | 3pcs / 4pcs Epson i1600-U1 Printheads |

| Print Size | 60cm |

| Print Height | 0-2mm |

| Colors | GL+CMYK+W+V+GV |

| Max Print Speed | 8 m/h |

| RIP Software | Future RIP |

Epson i3200 30cm | Max Printing Speed 7.2m/h

UV DTF Printer MT-UV DTF 30

Powerful UV DTF Printer with Endless Creativity.

| Model Number | MT-UV DTF 30 |

|---|---|

| Printhead | EPSON I3200-U1HD |

| Print Size | 30cm |

| Print Height | 0-1mm |

| Colors | CMYK + W + Varnish |

| Max Print Speed | 7.2 m/h |

| RIP Software | Future RIP |

|

MT -UV DTF 60

|

MT-UV DTF 30

|

|

3pcs / 4pcs Epson i1600-U1 Printheads

|

EPSON I3200-U1HD

|

|

60cm

|

30cm

|

|

0-2mm

|

0-1mm

|

|

GL+CMYK+W+V+GV

|

CMYK + W + Varnish

|

|

8 m/h

|

7.2 m/h

|

|

Future RIP

|

Future RIP

|

Model Number |

|---|

Printhead |

Print Size |

Print Height |

Colors |

Max Print Speed |

RIP Software |

UV DTF Printer: Professional Crystal Sticker & Transfer Printing

A UV DTF printer combines UV printing technology with direct-to-film transfer methods to create durable, vibrant crystal stickers that adhere to virtually any hard surface. Unlike traditional UV printers that print directly onto objects, these systems print onto special film that's then transferred—making them perfect for curved surfaces, bottles, irregular shapes, and products that won't fit under a flatbed printer.

MTuTech's UV DTF printing machines deliver professional results for businesses creating custom stickers, product labels, promotional items, and branded merchandise. From compact desktop models for startups to production systems handling thousands of transfers daily, our equipment combines reliable performance with the technical support you need to stay productive.

Print on: Glass, metal, wood, acrylic, leather, plastic, ceramic, electronics, bottles, promotional items

Understanding UV DTF Printer Technology

What Makes UV DTF Different

A UV DTF printer works by printing full-color designs plus white ink and varnish onto specialized PET film using UV-curable inks. Integrated UV LED lights instantly cure the ink as it prints. The system then automatically laminates a protective adhesive layer, creating a finished crystal sticker that can be applied to virtually any hard surface with simple peel-and-stick application.

The Complete Process:

Step 1: Design Printing

Full CMYK color plus white ink base and clear varnish prints onto UV DTF transfer film. White ink creates opacity for vibrant colors on dark or transparent surfaces.

Step 2: Instant UV Curing

Built-in UV LED lamps cure the ink immediately as it prints. No drying time, no waiting, no smudging.

Step 3: Automatic Lamination

The system applies and bonds the adhesive backing film, creating a protective sandwich structure with your design in the middle.

Step 4: Ready to Apply

Finished UV DTF transfers can be immediately applied, stored for later use, or sold as wholesale products. Application takes seconds: peel, stick, press, done.

Why Businesses Choose UV DTF Over Alternatives

Versus Direct UV Printing:

UV flatbed printers require objects to fit under the printer bed. UV DTF prints on film first, so you can decorate curved bottles, irregular shapes, textured surfaces, and items that would never fit in a flatbed system. The transfer flexibility opens applications impossible with direct printing.

Versus Vinyl Cutting:

Vinyl cutters are limited to solid colors and simple designs. UV DTF produces full-color photographic quality images with gradients, shadows, and fine details. No weeding, no layering multiple colors, no design limitations.

Versus Screen Printing:

Screen printing stickers requires setup time, color limitations, and minimum quantities. UV DTF handles full-color designs with zero setup, making single-piece orders as economical as bulk production.

Versus Standard DTF (Textile):

Regular DTF printers create heat transfers for fabric. UV DTF creates adhesive transfers for hard surfaces. Different technologies for different applications—most businesses offering custom decoration eventually need both.

UV DTF Printer Applications & Market Opportunities

Product Branding & Labels

Glass Bottles & Jars:

Craft beverage producers, specialty food companies, and cosmetics brands use UV DTF transfers to create premium labels that withstand refrigeration, handling, and moisture. The crystal-clear finish elevates perceived product value.

Promotional Products:

Custom phone cases, keychains, USB drives, pens, and corporate gifts. UV DTF transfers create professional branding that lasts through daily use and handling.

Electronics & Accessories:

Laptop covers, tablet cases, gaming peripherals, headphones. The transfers adhere permanently while maintaining the professional appearance required for consumer electronics.

Custom Sticker Business

Retail Stickers:

Sell custom designs online or at markets. UV DTF creates crystal stickers with dimensional appearance and premium feel that command higher prices than traditional vinyl stickers.

Automotive Decals:

Interior and exterior automotive decoration withstands temperature extremes, car washes, and UV exposure. Perfect for custom car culture and restoration projects.

Home Décor:

Decorative accents for furniture, walls, mirrors, picture frames. The transfers work on wood, glass, metal, and painted surfaces without damaging finishes.

Business & Signage

Interior Signage:

Directory signs, safety labels, instructional graphics, branding elements. UV DTF transfers apply to any flat or slightly curved surface including glass doors, metal fixtures, and painted walls.

Equipment Labeling:

Industrial equipment, machinery controls, inventory labels, asset tags. The durable transfers survive harsh environments while maintaining legibility.

Event & Exhibition Graphics:

Temporary branding for trade show booths, event décor, pop-up retail. Easy application and removal makes UV DTF ideal for temporary installations.

MTuTech UV DTF Printer Models

Entry-Level: MT-UV DTF 30

Print Width: 30cm (12")

Printhead: Epson i3200-U1HD

Speed: 7.2 m²/hour

Colors: CMYK + White + Varnish

Ideal For: Startups, small businesses, testing market demand

Perfect for entrepreneurs entering the custom sticker business without major capital investment. This compact system fits on a standard desk while delivering professional print quality that satisfies demanding customers.

What You Get:

All-in-one design with integrated laminator

Instant UV curing eliminates drying time

Professional 6-color printing (CMYK + White + Varnish)

Future RIP software included

Complete training and setup support

Production Capacity:

Handles 100-300 stickers daily depending on size. Perfect for custom orders, small production runs, and businesses building their customer base.

Best For: Home-based businesses, market vendors, online sticker shops, promotional product startups, businesses adding custom decoration to existing offerings.

Investment Range: Contact for current pricing on complete starter packages including consumables.

Production-Level: MT-UV DTF 60

Print Width: 60cm (24")

Printhead: 3-4x Epson i1600-U1

Speed: 8 m²/hour

Colors: GL+CMYK+White+Varnish+GV (9-color system)

Ideal For: Established businesses, production facilities, wholesale operations

Our flagship UV DTF system for businesses handling significant volume or requiring maximum color gamut. The expanded color set including gloss and matte varnish variations creates effects impossible with standard systems.

Advanced Capabilities:

Multi-head configuration for continuous production

Extended color gamut for specialty effects

Increased print width handles larger transfers

Industrial-duty construction for 24/7 operation

Automatic film feeding and tension control

Production Capacity:

Designed for 500-2000+ transfers daily. Handles both small custom orders and large production runs without equipment changes.

Special Features:

Dual varnish system (gloss + matte) for textured effects

Light color options for extended gamut and skin tone accuracy

Built-in redundancy minimizes downtime

Expandable configuration grows with your business

Who Needs This:

Contract decorators serving multiple clients, wholesale transfer producers, promotional product distributors, businesses replacing screen printing with digital flexibility, operations requiring consistent multi-shift production.

ROI Timeline:

High-volume operators typically report 4-6 month payback with proper pricing and marketing.

Complete Technical Specifications

| Specification | MT-UV DTF 30 | MT-UV DTF 60 |

|---|---|---|

| Print Width | 30cm (12") | 60cm (24") |

| Printhead | Epson i3200-U1HD | 3-4x Epson i1600-U1 |

| Max Speed | 7.2 m²/hour | 8 m²/hour |

| Resolution | Up to 1440 DPI | Up to 1440 DPI |

| Colors | CMYK + W + V (6-color) | GL+CMYK+W+V+GV (9-color) |

| Print Height | 0-1mm | 0-2mm |

| Curing System | Integrated UV LED | Integrated UV LED |

| Lamination | Automatic (built-in) | Automatic (built-in) |

| RIP Software | Future RIP | Future RIP |

| Film Type | UV DTF transfer film | UV DTF transfer film |

| Power | 220V | 220V |

All Models Include:

Integrated laminator (no separate equipment needed)

UV LED curing system

Automatic film feeding

RIP software with full functionality

Training and installation support

Warranty coverage on components

UV DTF Printing Technology Deep Dive

The UV Curing Advantage

Traditional printing relies on evaporation or absorption for ink drying. UV curing uses ultraviolet light to trigger instant chemical polymerization that transforms liquid ink into solid plastic in milliseconds.

Why This Matters for Your Business:

Instant Production

Print and laminate in one continuous process. Transfers emerge ready to use with zero waiting. This eliminates bottlenecks and allows immediate order fulfillment.

Superior Durability

The chemical curing process creates molecular bonds stronger than air-dried or heat-cured inks. UV DTF transfers withstand:

Commercial dishwashers (when applied to drinkware)

Extended UV sun exposure without fading

Chemical cleaning products

Abrasion and handling

Temperature extremes from -40°F to 180°F

Environmental Advantages

UV inks contain no VOCs (volatile organic compounds) and emit no odor during curing. No ventilation requirements beyond normal office air circulation. The process generates no hazardous waste requiring special disposal.

The Crystal Sticker Structure

Understanding the layered construction explains why UV DTF transfers perform so well:

Layer 1: Backing Film (Removable)

Protective carrier that's peeled away after application. Prevents damage during handling and storage.

Layer 2: Adhesive Layer

High-tack, permanent adhesive bonds to virtually any clean, dry surface. Formulated specifically for hard substrates rather than fabric.

Layer 3: Ink Layer

Your full-color design with white base and clear varnish top coat. The UV-cured inks maintain color accuracy and detail indefinitely.

Layer 4: Base Film (Removable)

Peeled away during application, leaving only the thin ink layer and adhesive on the surface.

Final Result:

A flexible, durable graphic that conforms to slightly curved surfaces while feeling almost painted-on rather than applied. Typical thickness: 50-100 microns (thinner than a credit card).

White Ink Technology

White ink serves as the foundation for vibrant colors on dark or transparent surfaces. Understanding its role helps optimize print quality:

On Dark Surfaces:

White ink prints first, creating an opaque base layer. Color inks print on top of the white, appearing vibrant regardless of substrate color underneath.

On Transparent Surfaces:

White ink creates opacity where needed while allowing transparency elsewhere. This enables creative effects like stained glass appearance or partial window coverage.

Print Order Matters:

The printer deposits white ink, then immediately prints CMYK colors while the white is still wet. This creates perfect registration and color accuracy. Finally, clear varnish seals everything.

Circulation System:

White ink contains titanium dioxide pigments that settle when idle. MTuTech systems include automatic circulation that keeps white ink properly suspended, preventing clogs and ensuring consistent coverage.

Operating Economics & Business Planning

Equipment Investment

Entry System (MT-UV DTF 30): $X,XXX - $X,XXX

Complete starter package including printer, initial consumables, training.

Production System (MT-UV DTF 60): $X,XXX - $X,XXX

Industrial configuration with extended features and capacity.

Contact us for current pricing, financing options, and available promotions

Consumable Costs Per Transfer

For typical 4" x 4" crystal sticker:

UV DTF transfer film: $0.08 - 0.15

Backing film: $0.05 - 0.10

UV ink (all colors): $0.12 - 0.20

Varnish: $0.03 - 0.05

Total materials: $0.28 - 0.50

Labor costs:

Minimal. The automated process requires loading film rolls and monitoring production. One operator easily manages 100-200+ transfers per hour.

Revenue Opportunities & Pricing

Retail Custom Stickers:

Small (2"-4"): $3-8 each

Medium (4"-6"): $8-15 each

Large (6"-10"): $15-30 each

Wholesale UV DTF Transfers:

Bulk pricing to other decorators: $1-5 per transfer depending on size and quantity.

Product Branding Services:

Custom labels for bottles, packaging, products: $0.75-3.00 per piece at volume.

Promotional Products:

Decorated items (phone cases, drinkware, etc.): $5-25 markup per item depending on product cost.

Sample Business Model: Custom Sticker Shop

Investment: $8,000 (entry system + startup inventory)

Average order: 12 stickers at $6 each = $72

Material cost per order: $6

Labor (15 minutes): $5

Gross profit per order: $61

Orders needed for payback: 132 orders

Timeline at 3 orders/day: 44 days

This conservative model shows profitability quickly. Most successful operators exceed these numbers significantly with proper marketing.

What You Need Beyond the Printer

Essential Requirements

Work Surface:

Stable table approximately 4' x 2' for the MT-UV DTF 30 model or 6' x 2' for the MT-UV DTF 60. Standard folding tables work fine; no special installation required.

Computer:

Windows-based PC or laptop (Mac not compatible with RIP software). Minimum 8GB RAM, modern processor. Most computers purchased within last 5 years work perfectly.

Power:

Standard 220V outlet. Many models include voltage adapters for different regional standards. Total power consumption comparable to a standard home appliance.

Design Software:

RIP software included handles printing. For creating designs: Adobe Illustrator, Photoshop, CorelDraw, or free alternatives like GIMP or Inkscape. If you can create a PNG or JPG file, you can print it.

Consumables Inventory

UV DTF Transfer Film:

Keep 2-3 rolls on hand. Typical roll: 30m or 60m length. Shelf life: unlimited when stored properly (away from direct sunlight, room temperature).

Backing Film:

Adhesive carrier film. Stock 2-3 rolls matching your transfer film width. Unlimited shelf life.

UV Ink:

Full set includes CMYK, White, and Varnish. One set typically prints 1000-2000 transfers depending on coverage. Shelf life: 12+ months sealed.

Varnish:

Clear protective coating. Consumption rate lower than color inks; one bottle lasts several thousand transfers.

Facility Requirements

Space:

Fits in home office, garage, small commercial space. No special ventilation beyond normal room air circulation.

Temperature:

Room temperature, 60-80°F ideal. Avoid direct sunlight on equipment. Standard air conditioning environments work perfectly.

Humidity:

Moderate humidity (40-60%) ideal for optimal ink performance and film handling.

Noise:

Quieter than most commercial printers. Quiet enough for home office or retail environments without disturbing neighbors or customers.

MTuTech Support & Training

Included with Every UV DTF Printer Purchase

Remote Installation Support:

Scheduled video session with technician walks you through unpacking, assembly, initial calibration, and first test prints. Typically 1-2 hours. We stay on the call until you're printing successfully.

Operation Training:

Learn design preparation, color management, printer operation, maintenance procedures, troubleshooting basics, and optimization techniques. Self-paced video modules plus live Q&A sessions available.

Technical Support Access:

Direct phone and email support with actual technicians who know the equipment. Response during business hours typically within 2-4 hours. No ticket systems, no outsourced call centers.

Troubleshooting Resources:

Video library covering common issues, preventive maintenance, repair procedures, and optimization tips. Searchable knowledge base with solutions to hundreds of scenarios.

Parts & Consumables:

Common maintenance parts and consumables ship within 24 hours. Critical components like printheads available for next-day delivery in most regions.

What Makes MTuTech Support Different

We Answer When You Call:

Your business depends on equipment uptime. When you have a deadline and need help, you reach people who can actually help—not a voicemail system or ticket queue.

Real Expertise:

Our technicians work with this equipment daily. They've seen every issue, handled every scenario, and can diagnose problems quickly rather than reading from scripts.

Business Partnership:

We succeed when you succeed. Your growth means you'll eventually upgrade equipment or refer other customers. This alignment means we're genuinely invested in your business success.

Extended Support Options Available

Priority Support Packages:

After-hours emergency support, expedited parts shipping, annual preventive maintenance visits, extended warranty coverage beyond standard terms.

On-Site Installation:

Available in major markets. Technician travels to your location for complete equipment setup, operation training, and process optimization. Typical visit: full day comprehensive training.

Advanced Training:

Specialized courses covering color management, specialty applications, production workflow optimization, advanced troubleshooting, business development strategies.

Getting Started with MTuTech UV DTF

Step 1: Consultation

Schedule call or video meeting to discuss:

Your business goals and target applications

Expected production volume

Experience level with printing equipment

Space availability and power requirements

Budget parameters

No pressure, no sales tactics. We ask questions to understand your situation, then recommend equipment that actually fits your needs. If UV DTF isn't the best solution for your application, we'll tell you honestly.

Step 2: Equipment Recommendation

Based on consultation, receive recommendation including:

Specific printer model suited to your volume and applications

Required consumables for startup

Optional accessories that might benefit your operation

Complete investment breakdown with no hidden costs

Step 3: See Technology in Action

Multiple options available:

Watch demonstration videos showing actual production

Schedule live video tour with equipment running and producing real transfers

Speak with existing customers about their experience

Request physical samples of UV DTF transfers to evaluate quality

Visit our facility if local (appointments recommended)

Step 4: Detailed Quote

Receive comprehensive pricing:

Complete printer system with standard accessories

Starter consumables package (enough for 100-500 transfers)

Shipping costs

Payment options and financing availability

Optional upgrades or accessories

Transparent pricing, no surprises.

Step 5: Order & Delivery

Payment Options:

Credit card (Visa, MC, Amex)

Wire transfer

Financing available for qualified businesses

Lease-to-own programs for some configurations

Equipment typically ships within 5-7 business days. Full tracking provided. Insurance coverage included.

Step 6: Installation & Training

Upon delivery:

Schedule remote installation session at your convenience

Technician guides complete setup via video call

Run test prints to verify performance and calibration

Complete hands-on training with your actual designs

You're ready to accept customer orders

Typical timeline from order to first production: 10-14 days

Frequently Asked Questions

About UV DTF Technology

What surfaces can UV DTF transfers be applied to?

Glass, metal, wood, acrylic, ceramic, plastic, leather, painted surfaces, and many others. Basically any clean, dry, hard surface. Not suitable for fabrics—use regular DTF printers for textiles.

How durable are UV DTF transfers?

When properly applied, transfers withstand 50+ dishwasher cycles, extended UV sun exposure, chemical cleaners, and daily handling. Expected lifespan: 5+ years outdoors, essentially permanent indoors.

Can transfers be removed?

Yes, but removal damages the transfer—they're designed as permanent decoration. Use a razor blade to lift an edge, then peel carefully. Adhesive residue may remain (clean with adhesive remover).

What's the difference between UV DTF and regular DTF?

Regular DTF creates heat transfers for fabric (t-shirts, hoodies, etc.). UV DTF creates adhesive transfers for hard surfaces (glass, metal, wood, etc.). Different technologies for completely different applications.

Do I need a laminator?

No. MTuTech UV DTF printers include integrated automatic lamination. The film emerges as finished, ready-to-apply transfers. No separate equipment needed.

About Business Operations

What's the learning curve?

Most operators produce sellable transfers within first few hours. The automated process handles the technical aspects; you focus on loading designs and monitoring production. Full proficiency typically within one week.

What maintenance is required?

Daily: 5-minute printhead cleaning cycle (automated)

Weekly: Check ink levels and film supply (5 minutes)

Monthly: Deep cleaning and calibration (20 minutes)

Much simpler than maintaining textile DTF or DTG equipment.

Can I print on pre-cut shapes?

The printer outputs continuous film that you cut to size after printing. Most operators use a standard paper cutter for straight edges or die-cutting equipment for custom shapes.

What's the minimum order quantity?

Zero. Print one transfer or one thousand with identical setup. Single-piece custom orders are just as economical as bulk production.

About Costs & ROI

What's the true cost per transfer?

For a 4" x 4" crystal sticker: $0.28-0.50 in materials. Add your labor and markup for retail pricing. Most shops charge $5-10 for this size, creating strong margins.

How much should I charge customers?

Market rates vary by location and customer type. Research local competitors. Typical retail: $3-30 per sticker depending on size. Wholesale/bulk: $1-5 per transfer depending on volume.

What's realistic production capacity?

Entry system: 100-300 transfers daily

Production system: 500-2000+ transfers daily

Actual output depends on design complexity, operator efficiency, and workflow organization.

How long until equipment pays for itself?

Highly variable based on pricing and volume. Home-based businesses typically see 3-6 month payback. Established businesses adding UV DTF often recoup investment in 2-3 months with proper marketing.

About Support & Service

What if I need help after purchase?

Direct phone and email support with technicians. Most inquiries answered within 2-4 hours during business hours. Emergency support available for priority support customers.

How fast can I get replacement parts?

Common items ship within 24 hours. Critical components like printheads available next-day in most locations. We stock parts locally to minimize downtime.

Is training really included?

Yes. Remote installation support, operation training, and troubleshooting resources included with every system at no additional charge.

Do you buy back used equipment?

We consider trade-ins when customers upgrade to larger systems. Contact us with equipment details for evaluation.

Why Businesses Choose MTuTech UV DTF Printers

Reliability Drives Revenue

"We researched six different UV DTF brands before choosing MTuTech. Nine months in, zero regrets. The equipment runs consistently, support answers when we call, and our downtime has been essentially zero. That reliability translates directly to customer satisfaction and referrals." – David L., Custom Promotional Products

Support Makes the Difference

"Had a technical issue during our busiest season. Called support at 3 PM, tech walked me through diagnosis in 10 minutes, had replacement part shipped same day, back in production next morning. That's the difference between losing $2,000 in orders versus delivering on time." – Rachel M., Sticker & Label Shop

Technology That Grows With You

"Started with the 30cm model printing stickers for my Etsy shop. Within four months, added the 60cm system to handle wholesale accounts. The technology is identical, so training was easy. Now we're doing $15K monthly revenue from an $8K initial investment." – Marcus T., Online Retail

From Traditional to Digital

"We did screen printed stickers for 20 years. Setup time and minimum quantities killed small orders. Switched to UV DTF and immediately captured the custom market we'd been turning away. First month paid for 40% of the equipment. Within six months, UV DTF revenue exceeded our traditional screen printing." – Jennifer K., Commercial Printing

Ready to Start Your UV DTF Business?

Contact MTuTech Today

Phone:+8613564008182

Email:admin@mtutech.com

Business Hours: Monday-Friday 9 AM - 6 PM EST

After Hours: Leave voicemail for next-business-day callback

Schedule Free Consultation:

Request a Quote

Request Information Package:

Visit Our Demonstration Facility

Address:Building 6, No. 99, Lane 1919, Duhui Road, Minhang District, zip code 201108, Shanghai China.

See UV DTF technology running in person. Watch live production, examine finished transfers, bring your design files for sample printing. Most visitors find 60-90 minute appointments sufficient to evaluate the technology and ask questions.

Schedule appointment:Contact Us Now

Get Complete Startup Package Pricing

Contact us for current pricing on turnkey packages:

Your choice of UV DTF printing system

Starter consumables (enough for first 500 transfers)

Complete training and setup support

30 days priority technical support

Optional: business planning and marketing consultation

Financing available for qualified businesses

About MTuTech

MTuTech specializes in professional digital printing equipment for businesses serious about quality, reliability, and support. We work exclusively with manufacturers who share our commitment to proven technology, quality components, and honest performance claims.

Our Difference:

We don't sell equipment—we build partnerships. Your success drives our reputation, which is why support doesn't end after delivery. We're available throughout your equipment's life because we're invested in your business growth.

Industry Experience:

Over a decade specializing in UV printing, DTF printing, and textile decoration technologies. Our team includes former print shop owners who understand production pressures, deadline stress, and equipment reliability requirements.

Quality Standards:

All equipment manufactured in ISO-certified facilities with comprehensive testing protocols. Compliance with regional electrical and safety standards verified before shipping.

Global Service:

We ship worldwide with full tracking and insurance. International customers receive the same support and service as domestic accounts, with technical support available via phone, email, and video.

Customer Success:

From home-based startups to production facilities, our customers build profitable businesses using MTuTech equipment. Read their stories, see their work, and contact them directly to hear honest feedback.

Additional Educational Resources

Learn More About UV DTF Printing

Technology Guides:

UV DTF vs UV flatbed printer comparison

Understanding crystal sticker markets

Design optimization for best results

Color management for accurate output

Business Resources:

Starting a custom sticker business

Pricing strategies for profitability

Marketing UV DTF services effectively

Scaling from startup to production facility

Application Tutorials:

Glass and bottle decoration techniques

Automotive decal production

Promotional product decoration

Creating metallic and special effects

Get Your Free Consultation & Quote Today

Call +8613564008182 or Email admin@mtutech.com