Best Practices for Cleaning and Maintaining Cylindrical Printers

Best Practices for Cleaning and Maintaining Cylindrical Printers

Introduction

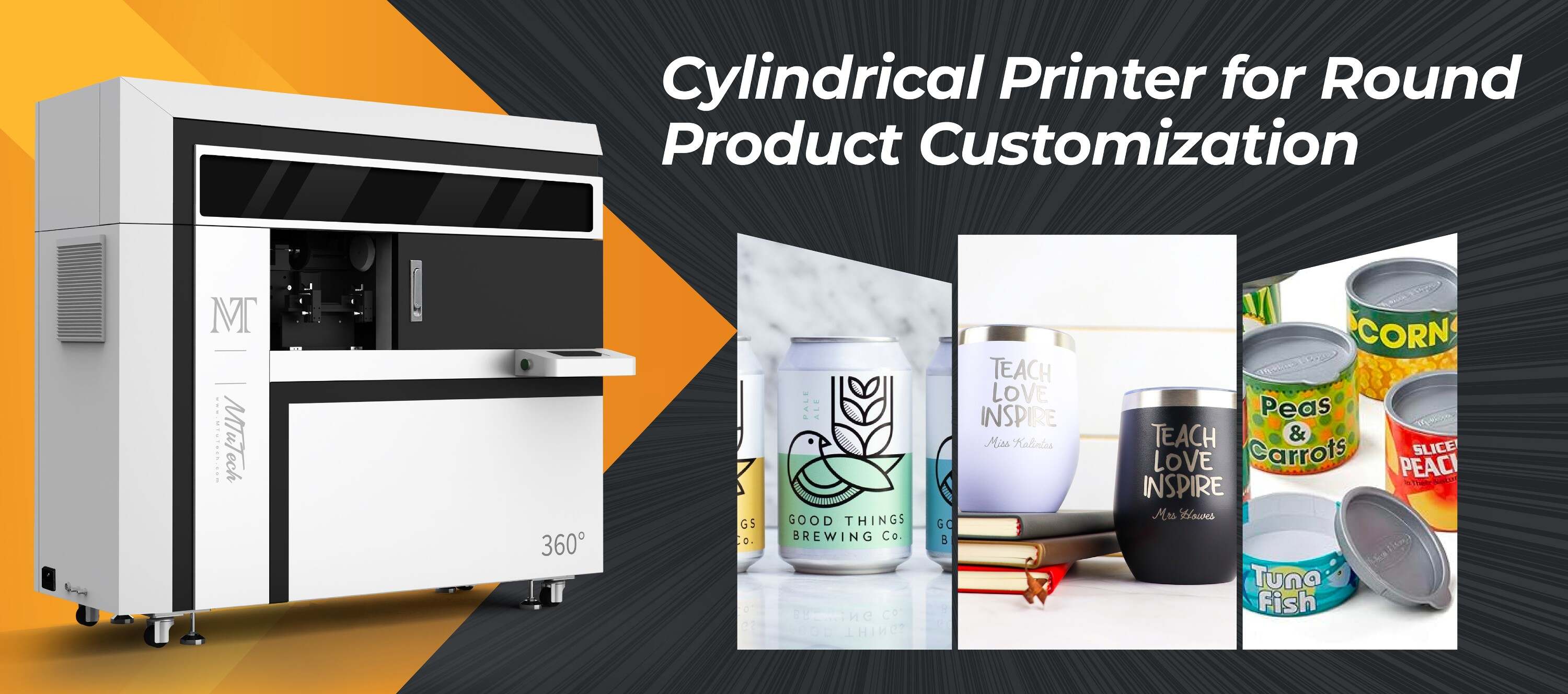

Cylindrical printers are innovative machines that bring efficiency and creativity to the printing world, especially in industries that require custom solutions for cylindrical objects like bottles, cans, and tubes. Like any sophisticated machinery, keeping these printers in optimal condition necessitates regular cleaning and maintenance. In this blog post, we will delve into the best practices for cleaning and maintaining cylindrical printers to ensure they operate seamlessly and yield quality prints consistently.

Why Cleaning and Maintenance Matter

Proper cleaning and maintenance of cylindrical printers come with a number of benefits:

·

Enhanced Print Quality: Regular cleaning prevents ink build-up and residue accumulation, ensuring sharp and vibrant results.

·

·

Extended Lifespan: Routine maintenance helps identify issues before they lead to major malfunctions, prolonging the machine's operational life.

·

·

Cost Efficiency: Investing time in maintenance can save money in the long run by reducing repairs and the need for early machine replacement.

·

·

Increased Efficiency: Well-maintained printers operate more smoothly, allowing for faster production times and improved workflow.

·

Key Components of Cylindrical Printers

Understanding the main components of cylindrical printers can help in effectively cleaning and maintaining them. Here are the vital parts to consider:

·

Print Head: The print head is crucial for ink delivery and needs frequent cleaning to avoid clogs.

·

·

Rollers: Rollers should be kept clean and lubricated for smooth printing operation.

·

·

Ink Reservoir: Inspecting and cleaning the ink reservoir prevents contamination and ensures consistent pigment flow.

·

·

Other Auxiliary Components: This includes software, belts, and settings that also require periodic checks and maintenance.

·

Best Practices for Cleaning Cylindrical Printers

1. Establish a Regular Cleaning Schedule

Create a timetable for cleaning your cylindrical printer. Depending on usage, daily, weekly, and monthly tasks can be established:

·

Daily: Wipe down the exterior, clean the print head, and check for ink build-up.

·

·

Weekly: Inspect rollers and other components for dust or residues, updating software settings as necessary.

·

·

Monthly: Conduct a thorough cleaning of the ink reservoir and check the overall functionality of the machine.

·

2. Use Appropriate Cleaning Supplies

Using the right cleaning materials is essential for avoiding damage:

·

Lint-Free Cloths: Use lint-free cloths to avoid leaving particles that can affect print quality.

·

·

Compatible Solvents: Use cleaning solutions specifically designed for your printer's ink type based on the manufacturer’s recommendations.

·

·

No Abrasive Cleaners: Avoid harsh chemicals that may scratch or damage the printer surfaces.

·

3. Clean the Print Head

The print head is fundamental to achieving high-quality prints. Here’s how to clean it:

·

Turn off the printer and unplug it.

·

·

Remove the print head according to the manufacturer’s instructions.

·

·

Soak the print head in a suitable cleaning solution for about 30 minutes.

·

·

Use a lint-free cloth to gently wipe away any remaining residue.

·

·

Reinstall the print head and run a test print to ensure proper operation.

·

4. Maintain the Rollers

Dirty rollers can lead to uneven printing. To keep them in prime condition:

·

Inspect the rollers for ink residue or dust accumulation.

·

·

Use appropriate cleaning solutions to wipe down the rollers.

·

·

Maintain lubrication as per the manufacturer’s guidelines.

·

5. Check the Ink Reservoir

Regularly monitoring the ink reservoir ensures uninterrupted printing:

·

Examine the reservoir for contamination or clogs regularly.

·

·

Replace cartridges promptly when ink levels are low.

·

·

Clean any spills immediately to prevent ink from corrupting other components.

·

6. Software Maintenance

Keeping the software updated is just as important as hardware maintenance:

·

Regularly check for firmware updates from the manufacturer.

·

·

Backup settings and configurations before performing updates.

·

·

Optimize software settings to align with your printing needs.

·

Common Maintenance Tips

Beyond basic cleaning, here are some additional maintenance tips:

·

Monitor Performance: Keep track of print quality and machine performance. Any noticeable decline should trigger an inspection.

·

·

Utilize Manufacturer Guides: Always refer to the user manual for specific maintenance and cleaning instructions tailored to your printer model.

·

·

Ask Experts: Don’t hesitate to seek professional help whenever you face complex issues or need advanced maintenance.

·

Conclusion

Maintaining and cleaning cylindrical printers is an integral part of keeping these machines running smoothly and effectively. By implementing a regular cleaning schedule, using the right supplies, and proactively addressing potential issues, you can ensure high-quality prints and extend the lifespan of your equipment. For those seeking high-quality cylindrical printing solutions, explore our high-quality cylindrical printers here. Remember, a clean machine is a productive machine!

FAQ

How often should I clean my cylindrical printer?

The frequency of cleaning depends on usage, but a daily quick clean, weekly maintenance tasks, and monthly thorough cleans are recommended for optimal performance.

What are the best supplies for cleaning cylindrical printers?

Use lint-free cloths, compatible cleaning solvents, and avoid abrasive materials to prevent damage while cleaning your printer.

Can I use any cleaning solution for the print head?

No, use only cleaning solutions that are specifically recommended for your printer type and model. This will help avoid damage to the print head.

Is it necessary to maintain the software of my printer?

Yes, maintaining the software is crucial. Keeping it updated ensures that you benefit from improvements, fixes, and feature enhancements.

What symptoms indicate that my printer needs cleaning or maintenance?

Signs of necessary cleaning or maintenance may include clogged print heads, poor print quality, unusual noises during operation, or error messages from the printer.