Budget Breakdown: Setting Up a Small Cylinder UV Print Business

Introduction

Starting a small cylinder UV print business can be an exciting venture for those passionate about printing, design, and creativity. The rise of customization and personal branding provides an excellent opportunity to capitalize on these trends. However, establishing this type of business requires careful financial planning and budgeting. In this blog post, we will provide you with a comprehensive budget breakdown to help you set up your cylinder UV print operation efficiently.

Understanding Cylinder UV Printing

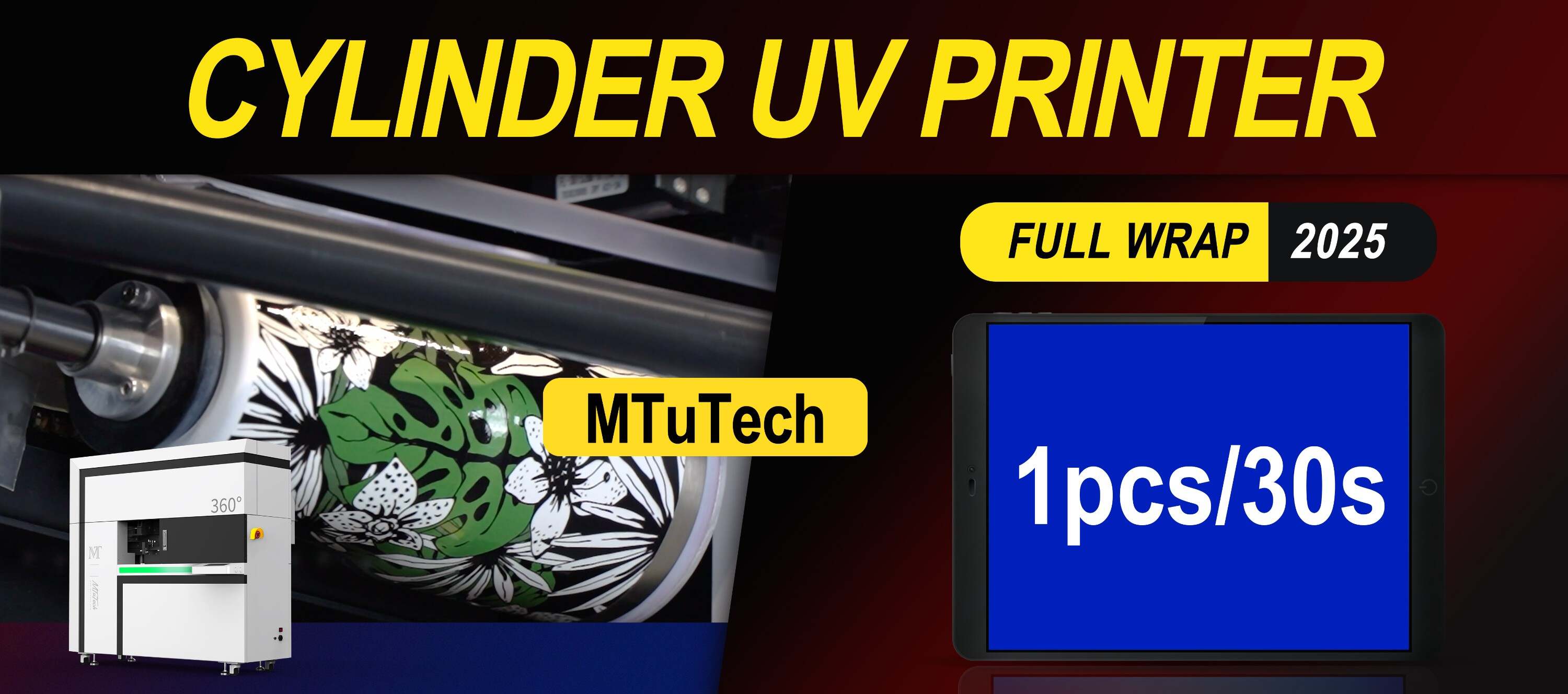

Cylinder UV printing is a technology that allows for the printing of high-quality graphics on cylindrical objects. This process uses ultraviolet light to cure or dry ink as it is printed, ensuring vibrant colors and a durable finish. Items such as bottles, cans, and promotional products can all benefit from this printing method.

Initial Investment: Key Components

When setting up a small cylinder UV print business, it is essential to identify the primary components that will contribute to your initial investment. The main expenses typically include equipment, materials, workspace, and operational overhead. Here’s a breakdown of each component:

1. Equipment Costs

·

Cylinder UV Printer: The most significant investment will be the printer itself. High-quality cylinder UV printers can range from $20,000 to $50,000 depending on features and capabilities. Make sure to consider the speed, color options, and software compatibility.

·

·

Computer and Software: You will need a reliable computer setup, typically costing between $1,500 to $3,000. Software for design and printing may cost an additional $500 to $2,000. Options like Adobe Illustrator or CorelDRAW are popular for design work.

·

·

Finishing Equipment: Depending on your services, you may require additional equipment such as adhesive applicators, curing stations, or cutting tools, which can add another $2,000 to $7,000 to your budget.

·

2. Material Costs

·

Inks and Coatings: The cost of inks can vary widely. Expect to spend around $100 to $300 per month on inks, depending on your volume of printing.

·

·

Substrates: Pricing for the materials you will print on (like bottles, cans, or promotional items) varies. A budget of $500 to $1,500 for initial stock is a good starting point.

·

·

Maintenance Supplies: Setting aside funds for cleaning agents and maintenance supplies will help keep your equipment in good working order. This could be around $200 to $500 annually.

·

3. Workspace Costs

·

Rental Costs: If you do not have adequate space at home, consider renting a small studio or workshop. Rental prices vary dramatically based on location, but budgeting around $500 to $2,000 a month is wise.

·

·

Utilities: Don’t forget to consider electricity and water bills, which could range from $100 to $500 monthly.

·

·

Insurance: Business insurance is essential for protecting your equipment and liability. Depending on coverage, expect to pay $500 to $2,000 annually.

·

4. Operational Overhead

·

Licensing and Permits: Depending on your local regulations, you might need permits for operating a printing business. Costs can range from $100 to $500.

·

·

Marketing and Branding: Developing a strong brand presence is crucial. Consider spending at least $500 to $2,000 on initial marketing efforts such as website development, social media promotion, and digital marketing.

·

·

Staffing Costs: If you plan to hire employees, factor in wages. Starting one-person operations can save costs, but if you expand, estimate around $25,000 per year for entry-level employees.

·

Total Estimated Startup Costs

Now that we have broken down the various components, let’s summarize the total estimated startup costs:

·

Equipment Costs: $23,500 - $62,000

·

·

Material Costs: $800 - $2,300 (initial stock and monthly operating costs)

·

·

Workspace Costs: $1,000 - $4,500 (rent, utilities, and insurance)

·

·

Operational Overhead: $1,200 - $4,000 (for marketing, licenses, and staffing)

·

Total: Approximately $27,500 to $72,800.

Funding Your Business

If the total initial investment seems daunting, various funding options may help you get started:

·

Personal Savings: Utilizing savings can be the quickest way to fund your business without incurring debt.

·

·

Small Business Loans: Look into local banks or credit unions that provide startup loans specifically for small businesses.

·

·

Grants and Competitions: Research available grants for entrepreneurs in your area, and consider entering business competitions.

·

·

Crowdfunding Platforms: Platforms like Kickstarter or Indiegogo can help raise funds while developing initial market interest.

·

Generating Revenue: Pricing Your Services

Next, it's critical to consider how you will price your services to ensure a profitable outcome. Pricing should be competitive while reflecting your quality and complexity of work. Here are factors to consider:

·

Cost of Materials: Calculate your cost per item, including substrates, inks, and labor.

·

·

Market Research: Research your competitors to see what they charge for similar services.

·

·

Value Additions: If you offer customization or unique designs, ensure these are reflected in your pricing.

·

Marketing Your Cylinder UV Print Business

With your business set up and pricing established, it's time to promote your services. Here are some effective marketing strategies:

·

Website and SEO: Create a user-friendly website that is optimized for search engines to attract customers searching online.

·

·

Social Media Marketing: Engage your audience through platforms like Instagram, Facebook, and Pinterest, showcasing your work and attracting new customers.

·

·

Networking: Build relationships with local businesses and attend trade shows to showcase your printing capabilities.

·

·

Email Campaigns: Collect emails from interested customers and send regular updates, promotions, and tips related to your services.

·

Conclusion

Setting up a small cylinder UV print business can be highly rewarding if done correctly. Although there is a considerable upfront investment, careful planning, creative marketing, and precise pricing strategies can lead to a successful and profitable venture. By utilizing the information in this budget breakdown, you will be well on your way to turning your passion for printing into a thriving business. Whether you're at the early stages of research or ready to take the plunge, ensuring you have all components aligned will be the key to your success.

FAQ

What is a cylinder UV printer?

A cylinder UV printer is a specialized printing machine designed to print high-quality images on cylindrical objects using ultraviolet light to cure the ink quickly.

What are the typical substrates used in cylinder UV printing?

Common substrates include plastic and metal bottles, cans, promotional items, and various cylindrical packaging products.

How much can I expect to earn from a small cylinder UV print business?

Earnings can vary widely based on your market niche, pricing, and volume of orders. However, many small businesses in this sector report profit margins between 20-40%.

Is cylinder UV printing environmentally friendly?

Yes, UV printing is often considered more environmentally friendly than traditional printing methods as it produces minimal VOC emissions and uses limited solvent-based inks.

How do I find clients for my cylinder UV print business?

Networking, social media, local advertisements, and partnerships with businesses that require custom printing services can help you build a client base.

Additionally, explore our high-quality Cylinder UV printers here for options that suit your startup needs and enhance your service offerings.