Can You Print on Powder-Coated Tumblers with UV Printers?

Can You Print on Powder-Coated Tumblers with UV Printers?

Introduction

The rise in popularity of personalized drinkware has led to new opportunities for customization in various industries. Among the various types of tumblers available, powder-coated tumblers have gained significant traction due to their durability and aesthetic appeal. However, when it comes to printing designs directly onto these tumblers, many professionals in the printing industry may wonder, "Can you print on powder-coated tumblers with UV printers?" In this blog post, we'll explore this question in detail and discuss the specifics of UV printing on powder-coated surfaces.

Understanding Powder-Coated Tumblers

Before diving into the printing process, it's essential to understand what powder-coated tumblers are and how they differ from other drinkware options.

What is Powder Coating?

Powder coating is a dry finishing process that involves applying a powdered paint to a surface, which is then cured under heat to form a hard, protective layer. This results in a durable and attractive finish that is resistant to chipping, scratching, and fading. Here are some key benefits of powder-coated tumblers:

·

Durability: Resistant to abrasion and wear.

·

·

Corrosion Resistance: Suitable for various environments.

·

·

Variety of Colors: Available in a wide range of colors and finishes.

·

·

Eco-Friendly: Generally considered more environmentally friendly than traditional liquid paints.

·

The UV Printing Process

Ultraviolet (UV) printing is a modern method of printing that uses UV light to cure or dry the ink as it is printed. This technique offers several advantages, particularly for customization and personalization:

Advantages of UV Printing

·

High-Quality Images: UV printing delivers vibrant colors and sharp details with excellent resolution.

·

·

Immediate Drying: The inks cure instantaneously, allowing for quick production cycles.

·

·

Versatility: Can be used on various materials, including glass, wood, and metal.

·

·

Eco-Friendly Inks: Many UV inks are eco-solvent and environmentally friendly.

·

Printing on Powder-Coated Tumblers

The main question remains: Can you print on powder-coated tumblers using UV printers? The answer is a cautious "yes," but there are several factors to consider to achieve the best results.

Surface Preparation

Successful printing on powder-coated surfaces requires proper surface preparation. Here are the steps to ensure optimal adhesion of the UV ink:

·

Clean the Surface: Remove any dust, oil, or residues by cleaning the tumbler thoroughly.

·

·

Light Abrasion: Lightly sand the surface or use a surface treatment to enhance ink adhesion.

·

·

Test Samples: Always run tests on a sample tumbler to assess ink adherence and appearance.

·

Ink Selection

The choice of ink is crucial when working with any substrate, especially powder-coated tumblers. Opt for high-quality UV inks designed for use on glossy or non-porous surfaces. These inks typically provide better adhesion and longer-lasting prints.

Best Practices for UV Printing on Powder-Coated Tumblers

To achieve high-quality results when printing on powder-coated tumblers, consider the following best practices:

Temperature and Humidity Control

Maintain ideal temperature and humidity levels in your printing environment. This will help the UV inks cure properly and avoid issues with adhesion or print quality.

Proper Printer Settings

Adjust your UV printer settings according to the characteristics of the powder-coated surface. This may involve adjusting the curing speed and height settings to ensure optimal ink transfer and adhesion.

Post-Printing Treatment

After printing and curing, it's essential to allow the tumblers to cool down before handling them. Additionally, consider applying a clear coat or protective layer to enhance durability and longevity.

Common Challenges and Solutions

As with any printing process, challenges can arise. Here are some common issues and their solutions:

Adhesion Problems

If you notice that the UV ink is peeling or chipping, it may be due to insufficient surface preparation or the wrong type of ink. Ensure that the surface is properly prepared, and test different inks if necessary.

Print Quality Issues

To address print quality concerns, such as blurriness or distortion, check that your printer's settings are appropriately adjusted for the coated surface. Regular maintenance of the printer can also help avoid these issues.

Conclusion

Printing on powder-coated tumblers with UV printers is a feasible option when done correctly. By understanding the intricacies of both the printing process and the substrate, businesses can effectively create beautiful, long-lasting designs on powder-coated tumblers. As this trend continues to grow, mastering this technique can set your business apart in the competitive world of custom drinkware.

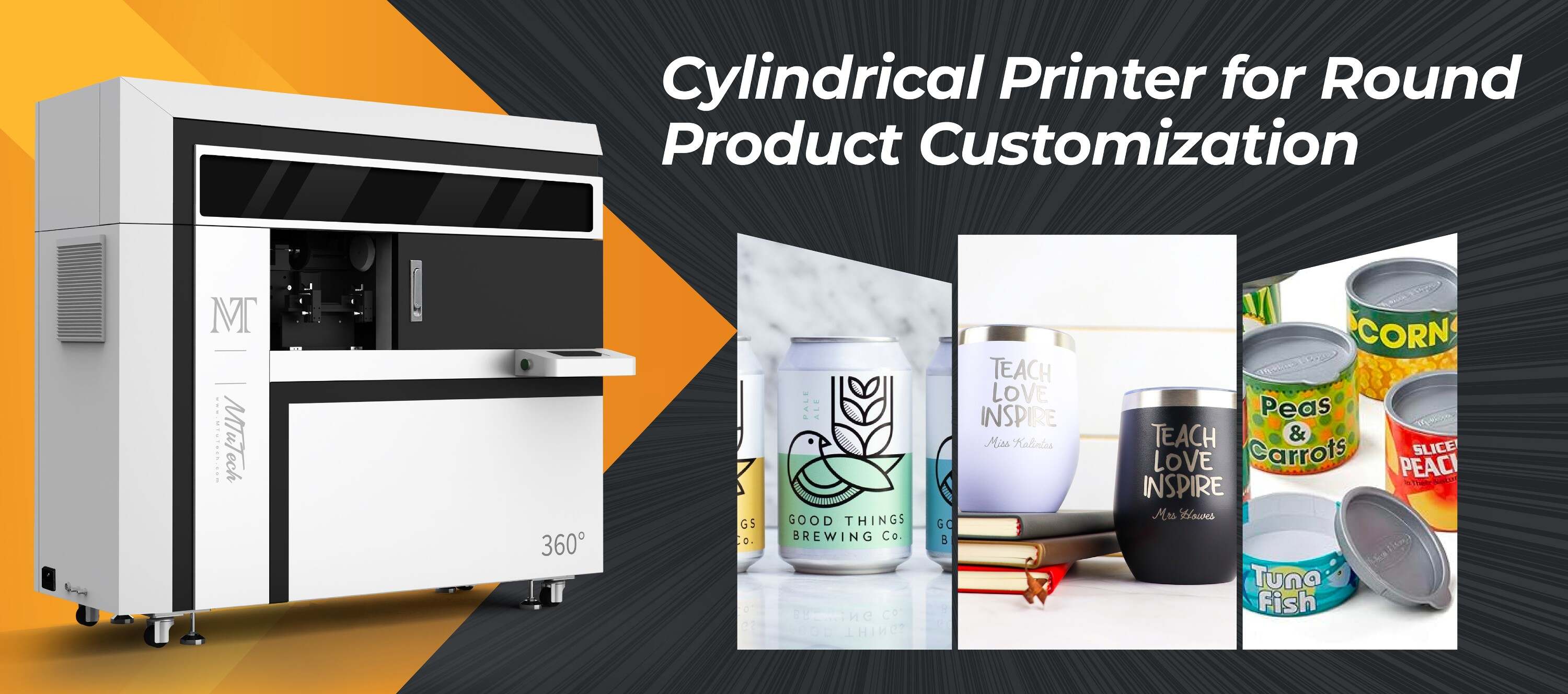

For those looking to invest in high-quality printers suitable for this type of work, explore our high-quality Tumbler printers here to take your customization game to the next level.

FAQ

Can all UV printers print on powder-coated surfaces?

No, not all UV printers are equipped to handle powder-coated surfaces. It's essential to use specialized UV inks and adjust printer settings to optimize adhesion and print quality.

Is pre-treatment necessary for powder-coated tumblers?

Yes, pre-treatment such as cleaning and possibly abrading the surface is crucial for achieving satisfactory results and long-lasting prints on powder-coated tumblers.

How durable are UV prints on tumblers?

UV prints can be quite durable, especially when the proper preparation and ink selection techniques are followed. However, applying a clear coat can enhance durability even further.

Are there any specific inks for printing on powder-coated tumblers?

Yes, specialized UV inks designed for non-porous and glossy surfaces are recommended as they provide better adhesion and more vibrant results.

Can I print any design on powder-coated tumblers?

Yes, you can print various designs, including photographs and logos, on powder-coated tumblers, provided you follow the right processes and use the correct inks.