Choosing Between Flatbed and Rotary for Tumbler Printing

Introduction

As the demand for customized drinkware continues to rise, many businesses are investing in tumbler printing technology. When it comes to choosing a printer, the two most popular options are flatbed and rotary printers. Both have unique strengths and applications, making the choice somewhat tricky. In this guide, we will explore the differences between flatbed and rotary printers, their benefits, and which may be the best fit for your specific needs.

Understanding Flatbed Printers

Flatbed printers are designed for printing on various materials, including those that are flat and rigid. These printers feature a flat printing surface where the tumbler is placed while it prints. Below are some key features and benefits of flatbed printing technology.

Features of Flatbed Printers

·

Versatility: Flatbed printers can print on a wide range of materials, including wood, glass, metal, and plastics.

·

·

High Resolution: These printers typically offer higher resolution printing, resulting in sharper images and finer details.

·

·

Thicker Substrates: Flatbeds can handle thicker items, making them ideal for custom jobs on larger or irregularly shaped surfaces.

·

Benefits of Flatbed Printing

·

Precision: The ability to print directly on the tumbler ensures that every inch is utilized effectively without the worry of distortion.

·

·

Color Range: Flatbed printers generally offer more vibrant colors, enhancing the quality of custom designs.

·

·

Easy Setup: Setting up a flatbed printer is typically straightforward, making it accessible for various skill levels.

·

Understanding Rotary Printers

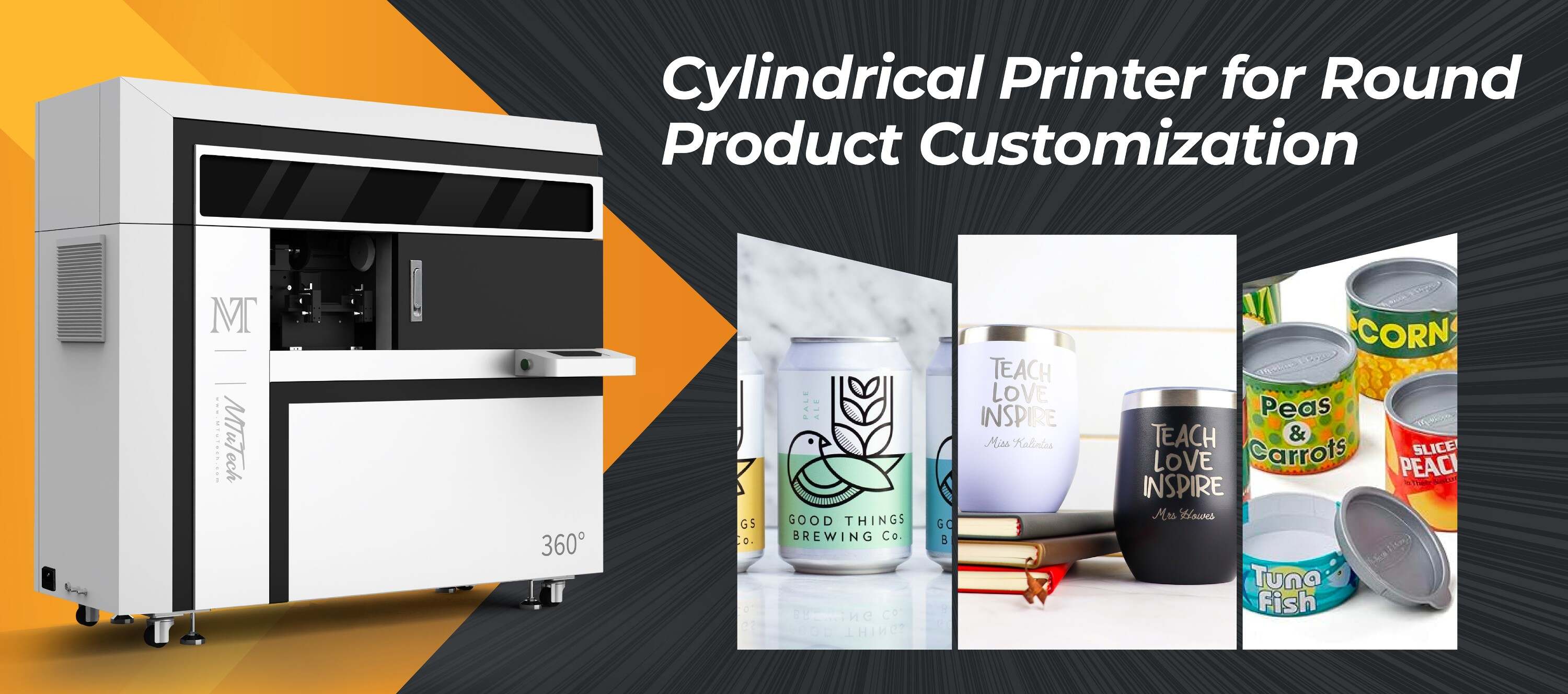

Rotary printers differ significantly from flatbed printers. They operate on a cylindrical printing surface, allowing for continuous feed of items like tumblers. Rotary printers are specifically designed for cylindrical objects, offering certain advantages that make them ideal for specific printing needs.

Features of Rotary Printers

·

Cylindrical Focus: Rotary printers are explicitly designed for printing on cylindrical objects, achieving even coverage and consistency.

·

·

Automated Processes: Many rotary printers come with automated features, allowing for faster production speeds and reduced labor costs.

·

·

Compact Size: Rotary printers often have a smaller footprint, making them suitable for businesses with limited space.

·

Benefits of Rotary Printing

·

Efficiency: Rotary printers excel in bulk production, making them ideal for businesses looking to produce high quantities quickly.

·

·

Less Waste: These printers often use less material as they print precisely on the intended surface, minimizing waste.

·

·

Consistent Quality: Rotary printing ensures uniformity in designs and colors, leading to high-quality results every time.

·

Factors to Consider When Choosing Between Flatbed and Rotary

Selecting the right printer for your tumbler printing needs involves evaluating several important factors. Here are some key considerations:

Production Volume

If your business aims to produce high volumes of tumblers quickly, a rotary printer may be the most suitable choice. Their automated features and efficiency lend themselves well to mass production. Conversely, a flatbed printer might be more appropriate if you're focusing on smaller, custom orders.

Print Quality

When it comes to print quality, flatbed printers often provide superior resolution and detail. If your business requires intricate designs, especially with various colors and effects, a flatbed printer may be your best bet.

Material Compatibility

Consider the materials you plan to print on. Flatbed printers can handle a wider range of substrates, whereas rotary printers are best suited for cylindrical items like tumblers and bottles. If your business may expand into different types of products in the future, flatbed printers offer more versatility.

Budget Constraints

When making a decision, factor in your budget for purchase and operation costs. Rotary printers tend to cost less up front and may save money in the long run due to their high efficiency and lower material waste. However, flatbeds offer greater versatility and may be worth the additional investment for a business focused on customization.

Space Requirements

The physical space available for your printing operation is another determining factor. Rotary printers often occupy less space, which can be a crucial consideration for smaller shops or businesses. Flatbed printers usually require more space due to their size and the need for ample setup.

Conclusion

Both flatbed and rotary printers present unique advantages and challenges for tumbler printing businesses. A flatbed printer excels at producing high-quality, intricate designs on a variety of materials, making it ideal for companies that prioritize customization. On the other hand, a rotary printer offers an efficient, automated solution for businesses focused on high-volume, consistent printing.

Ultimately, the best choice will depend on your specific needs, including production volume, budget, material compatibility, and available space. By carefully evaluating these factors, you can make a more informed decision. For businesses considering advanced customization solutions, you can explore our high-quality Tumbler printers here to find the right equipment for your needs.

FAQ

What is the main difference between flatbed and rotary printers?

The primary difference lies in the design: flatbed printers have a flat surface for printing on rigid substrates, while rotary printers have a cylindrical design specifically for printing on round surfaces like tumblers.

Which printer type is better for customization?

Flatbed printers are often considered better for customization due to their capability for high-resolution printing on a variety of materials, allowing for intricate designs and details.

Can I use a rotary printer for flat items?

Generally, rotary printers are not designed for flat items, as their mechanics are tailored for cylindrical printing. It’s advisable to use a flatbed printer for flat substrates.

Are rotary printers faster than flatbed printers?

Yes, rotary printers tend to be faster due to their automated processes and efficiency in producing high volumes of prints in a short time frame.

Can I print on different materials with a flatbed printer?

Yes, flatbed printers are versatile and can print on a wide array of materials, making them suitable for various customization projects beyond just tumblers.