Color Profiling for Consistency in Cylinder UV Printing

Introduction

In the world of printing, achieving consistency and accuracy in color reproduction is essential for maintaining brand integrity and satisfying customer expectations. This is particularly true for cylinder UV printing, a process that is gaining popularity for its versatility and ability to produce high-quality prints on various surfaces. One crucial aspect that contributes to color consistency in cylinder UV printing is color profiling. In this blog post, we will delve into the significance of color profiling, the methodology involved, and how it can enhance the overall effectiveness of your printing operations.

Understanding Cylinder UV Printing

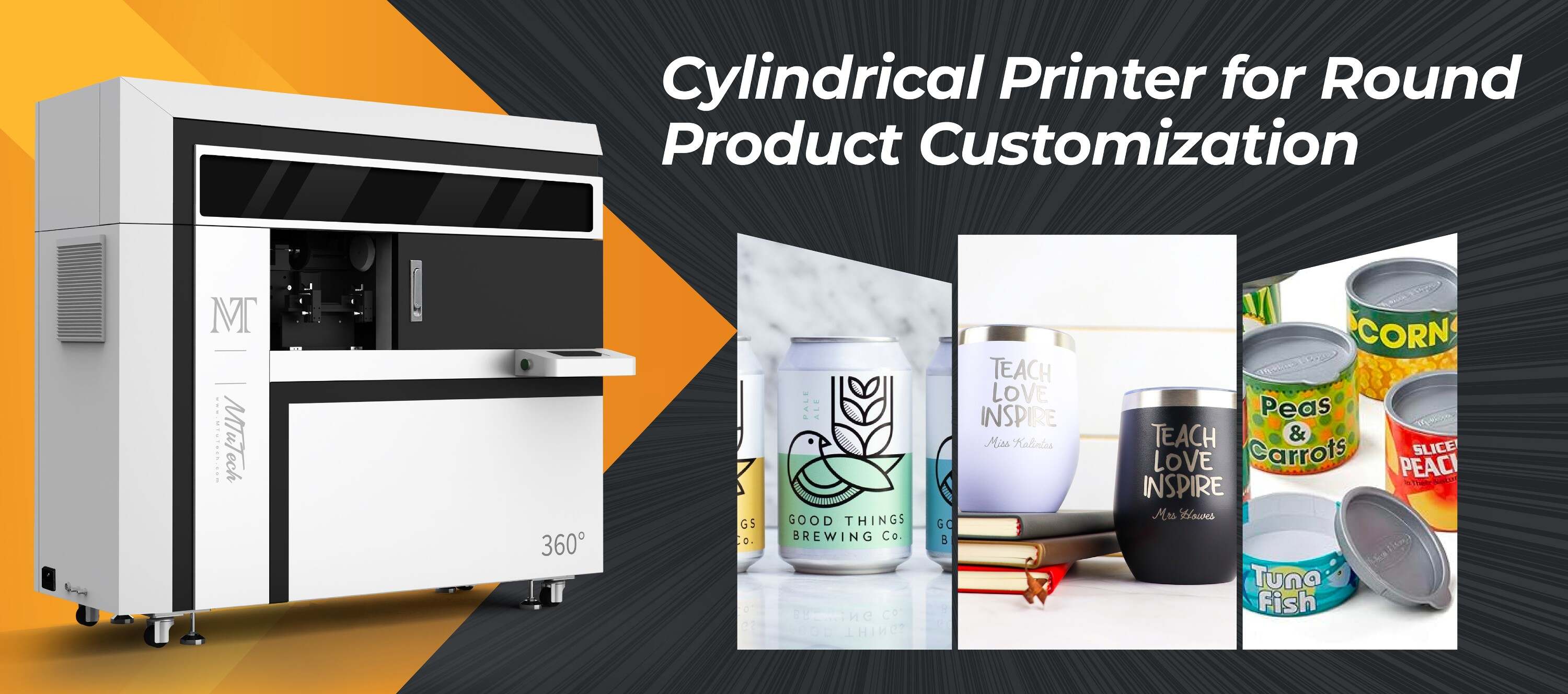

Cylinder UV printing involves printing on cylindrical objects, often found in packaging, promotional products, and custom items. This method uses ultraviolet light to cure or dry the ink as it is printed, resulting in a finish that is both durable and resistant to various environmental factors.

The Need for Color Consistency

Maintaining color consistency in cylinder UV printing is vital for several reasons:

·

Brand Consistency: For businesses, consistent color reproduction reinforces brand identity.

·

·

Customer Satisfaction: Customers expect the colors in the products they receive to match their expectations or graphics provided.

·

·

Reduced Waste: Inconsistent colors can lead to misprints, resulting in wasted materials and increased costs.

·

The Importance of Color Profiling

Color profiling is the process of creating a profile that defines how a specific device or printing process reproduces color. When it comes to cylinder UV printing, color profiling serves several critical functions:

1. Accurate Color Reproduction

Color profiling allows printers to accurately reproduce colors as specified in digital files. This reduces discrepancies between designs and final products, ensuring colors appear as intended across different batches.

2. Device Calibration

Each cylinder UV printer may have different characteristics affecting its color output. Color profiling helps calibrate the device, ensuring that it operates within expected parameters and achieves consistent results.

3. Optimized Ink Usage

By using color profiles, printers can optimize the amount of ink used for specific colors, thereby reducing costs and minimizing environmental impact. This optimization is crucial in ensuring that the ink enhances rather than detracts from the print quality.

Creating a Color Profile for Cylinder UV Printing

The process of creating a color profile involves several key steps:

Step 1: Calibration of Equipment

Before creating a color profile, ensure that all equipment, including the printer and computer monitors, are properly calibrated. This means checking that the printer is set to the correct configuration and that the screen displays colors accurately.

Step 2: Selecting a Color Target

Choosing the right color target is crucial for creating an effective profile. A color target is typically a printed sheet that contains a series of color patches representing various hues and saturation levels. This target will serve as the reference for color adjustments.

Step 3: Measuring Color Output

Once the color target is printed, use a color measurement device, such as a spectrophotometer, to measure the colors produced by the printer. The data collected will be compared to the known values of the color target.

Step 4: Generating the Color Profile

Using software designed for color profiling, you can create a profile based on the measurements taken. This profile will include information about how your printer reproduces color, allowing it to accurately match the color standards in the future.

Step 5: Testing and Refining

Once the color profile is established, conduct a test print to evaluate the results. Fine-tune the profile as necessary to achieve the desired color consistency. It’s advisable to repeat this process regularly to ensure ongoing accuracy.

Benefits of Implementing Color Profiling

Investing time and resources into color profiling can yield significant benefits for businesses engaged in cylinder UV printing:

·

Improved Quality Control: Consistent color output means higher quality prints, which can elevate the company's reputation.

·

·

Time Savings: By minimizing reprints due to color errors, companies can accelerate their production timelines.

·

·

Greater Flexibility: With the correct color profile, printers can adapt more quickly to new products or designs while maintaining color integrity.

·

·

Cost-Effectiveness: Lower ink consumption and reduced waste can lead to significant cost savings over time.

·

Challenges and Considerations

While color profiling offers many advantages, it also comes with challenges that need careful consideration:

1. Variability in Materials

The surface on which you are printing can significantly impact color output. Different materials may absorb ink differently, affecting color perception. Understanding the interaction between ink and substrate is crucial for accurate color profiling.

2. Environmental Factors

Lighting conditions under which colors are viewed can influence perceptions. Therefore, it's essential to establish ideal viewing conditions to assess color accuracy effectively.

3. Ongoing Maintenance

Color profiles can drift over time due to wear and changes in your printing environment. Ongoing maintenance and re-profiling are necessary to ensure that consistency is upheld.

Conclusion

Color profiling is a fundamental aspect of achieving consistency in cylinder UV printing. By understanding and implementing effective color profiling techniques, businesses can produce high-quality prints, enhance brand integrity, and improve customer satisfaction. While the process may have its challenges, the benefits far outweigh the drawbacks, making it an essential investment for any printing operation. To get started with enhancing your cylinder UV printing capabilities, explore our high-quality Cylinder UV printers here and ensure your printing process stands out in today’s competitive market.

FAQ

What is color profiling in printing?

Color profiling is the process of creating a profile that defines how a specific printing device reproduces colors. It ensures that the colors in the final print match the intended colors specified in design files.

Why is color consistency important in cylinder UV printing?

Color consistency is crucial for brand integrity, meeting customer expectations, reducing waste, and ensuring high-quality outputs. Inconsistent colors can lead to customer dissatisfaction and additional costs associated with reprints.

How often should I recalibrate my color profile?

It’s advisable to recalibrate your color profile regularly, especially when changing substrates, inks, or environmental conditions. Regular maintenance ensures ongoing accuracy in color reproduction.

What tools do I need for color profiling?

Essential tools for color profiling include a spectrophotometer for measuring color output and software designed for generating color profiles. Additionally, calibrated monitors are essential for ensuring accurate color display during the profiling process.

Can material changes affect color profiling?

Yes, changes in printing substrate can significantly influence the absorption and reflection of ink, which can alter the perceived color. It is critical to consider the material properties when developing or adjusting a color profile.