Cylindrical Packaging Design: Mistakes to Avoid with UV Printing

Introduction

In today’s competitive market, cylindrical packaging is gaining traction due to its unique aesthetic and practical advantages. Whether it’s for beverages, cosmetics, or food items, cylindrical designs can capture consumers' attention while offering functionality. However, when it comes to UV printing on these cylindrical packages, several mistakes can compromise the quality and effectiveness of the design. In this article, we will explore common pitfalls to avoid to ensure your cylindrical packaging looks its best and delivers optimal performance.

Understanding UV Printing

UV printing, or ultraviolet printing, is a modern printing technology that uses ultraviolet light to dry or cure ink as it is printed. This process delivers vibrant colors, sharp images, and durable finishes, making it an ideal choice for cylindrical packaging. However, specific challenges are inherent to this technology, especially when applied to three-dimensional surfaces.

Common Mistakes in Cylindrical Packaging Design

Poor Design Adaptation

One of the most significant mistakes in cylindrical packaging design is failing to adapt the design to the shape of the surface. Unlike flat surfaces, cylindrical packaging requires careful consideration of how the graphics will appear when wrapped around the curvature.

·

Ignoring the Wrap Effect: Designs can become distorted when wrapped around cylinders. Always preview how your artwork will look on the final product.

·

·

Skipping Prototype Testing: Utilize prototypes to assess design flaws or aesthetic issues before full production.

·

Neglecting Color Calibration

Color consistency is crucial in UV printing. Neglecting proper color calibration can lead to discrepancies between the digital design and the final print product.

·

Inconsistent Color Profiles: Always use the same color profiles across your design software and printer to ensure uniformity.

·

·

Overlooking Pantone Matching System (PMS): Utilize PMS guides to maintain consistent color across different batches of packaging.

·

Ignoring Material Selection

The choice of material can significantly affect the printing process and the final product's appearance. Selecting unsuitable materials may lead to various problems, such as poor ink adhesion, fading, or peeling.

·

Not Considering Surface Finish: A glossy or matte finish can dramatically change the appearance of colors. Choose the finish that best represents your brand.

·

·

Incompatible Materials: Ensure that the material you select is optimized for UV printing to achieve the best results.

·

Miscalculating Print Size and Resolution

Another common error is miscalculating the print size and image resolution, which can lead to blurred images or text that is hard to read.

·

Choosing Low Resolution: Always select a resolution of at least 300 DPI for high-quality prints.

·

·

Failing to Account for Bleeds: Design with appropriate bleeds to ensure that the ink extends to the edges of your cylindrical packaging.

·

Overcomplicating the Design

Less is often more in packaging design. Overcomplicating the design elements can overwhelm your audience and dilute your brand message.

·

Cluttered Graphics: Avoid excessive text and imagery. Focus on a clean design that effectively communicates your brand.

·

·

Using Too Many Colors: Limit your color palette to maintain brand consistency and improve visual appeal.

·

Failing to Consider Regulatory Requirements

Cylindrical packaging must often comply with various regulations, especially in industries like food and beverages. Ignoring these can lead to costly recalls and damage to your brand's reputation.

·

Missing Mandatory Information: Ensure all essential details, such as nutritional information and allergen warnings, are included in the design.

·

·

Non-compliance with Labeling Regulations: Research your industry’s specific labeling requirements to avoid legal issues.

·

Skipping Quality Control

Quality control is critical for ensuring the final product meets your standards and those of your consumers. Skipping this step can result in subpar packaging that reflects poorly on your brand.

·

Neglecting to Inspect Samples: Always review samples before mass production to catch potential issues.

·

·

Not Evaluating Print Performance: Test the durability of the print under various conditions, including exposure to moisture and light.

·

Best Practices for UV Printing on Cylindrical Packaging

Utilize Technology and Tools

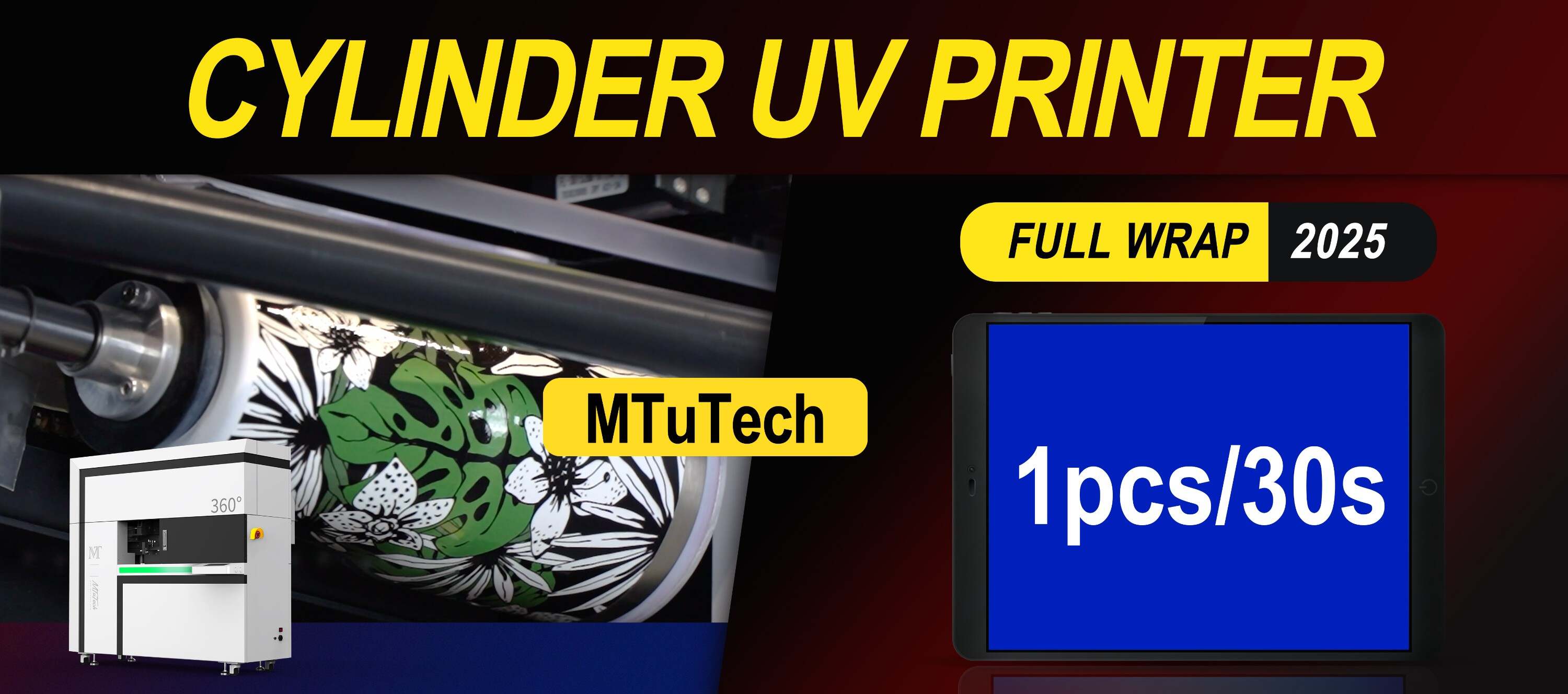

Modern printing technology has come a long way. Use high-quality printers specifically designed for cylindrical packaging, as they will often have features that optimize the UV printing process.

Incorporate Feedback and Revisions

Always seek input from your colleagues or focus groups to gather insights on the design. Use this feedback to refine your approach and avoid common pitfalls. A collaborative effort will produce a design that resonates with your target audience.

Stay Updated on Trends

The packaging industry is always evolving. Regularly researching trends in cylindrical packaging and UV printing can keep your designs fresh and appealing. Leverage innovative technologies to enhance visual appeal and improve user experiences.

Conclusion

Cylindrical packaging can offer significant advantages if executed correctly. By avoiding the common mistakes discussed in this article, you can ensure your UV printing process is efficient and results in eye-catching designs that enhance your brand image. Never underestimate the importance of research, proper planning, and quality control in delivering premium packaging solutions.

For those looking to elevate their printing capabilities, it may be worth exploring high-quality options like those available through Cylinder UV Printers. Investing in the right technology can be a game-changer for your business.

FAQ

What is UV printing?

UV printing is a digital printing method that uses ultraviolet light to cure or dry the ink during the printing process, resulting in high-quality prints with vibrant colors and sharp images.

Can UV printing be used on all types of materials?

No, not all materials are suitable for UV printing. It is essential to select materials that are compatible with UV inks to achieve optimal results.

Why is color calibration important in UV printing?

Color calibration ensures that the colors in your design are accurately reproduced in the final print. Inconsistent colors can negatively impact brand identity and customer trust.

How can I ensure my packaging design is compliant with regulations?

Research industry-specific regulations related to packaging and labeling. Ensure your design includes all necessary information to comply with these standards.

What should I do if I notice quality issues on my printed packaging?

If you notice any quality issues, it is crucial to halt production and conduct a thorough inspection. Address the issues immediately and test a new batch if necessary before proceeding.