Cylindrical Printer Parts Availability: OEM vs Third-Party Suppliers

Introduction

In the world of cylindrical printing, the quality of your products hinges not only on the printer itself but also on the availability of parts and supplies. When it comes to sourcing these essential components, businesses are often faced with a choice: original equipment manufacturer (OEM) parts or third-party suppliers. Each option presents unique advantages and challenges that can significantly impact your printing operations. This blog delves into the differences between OEM and third-party cylindrical printer parts availability, helping you make an informed decision for your business.

Understanding Cylindrical Printers

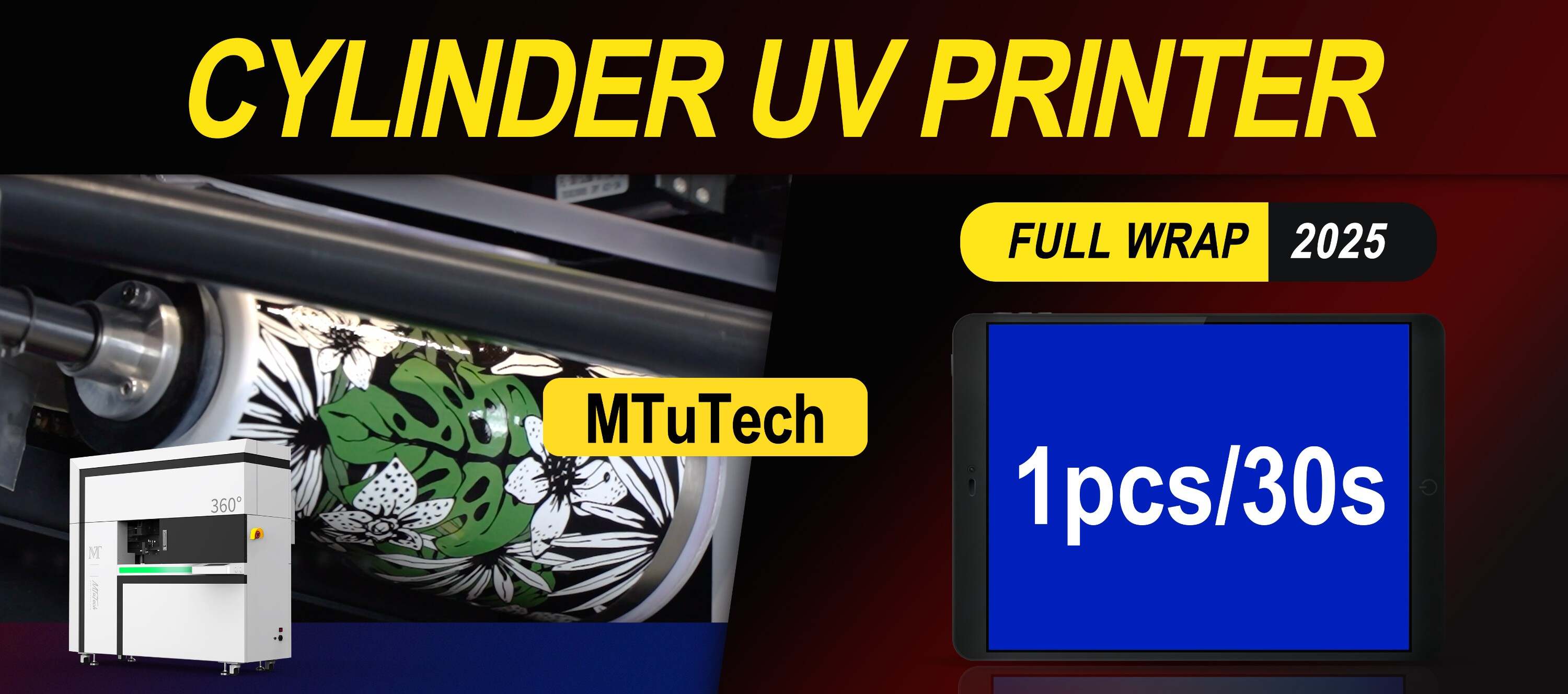

Cylindrical printers are specialized machines designed for printing on cylindrical objects like bottles, cans, and tubes. They employ advanced technology to ensure high-quality prints that can withstand the rigors of various environments. As a vital part of many production lines, maintaining the uptime and efficiency of these printers is crucial. This underscores the importance of having access to quality parts, whether from OEMs or third-party suppliers.

OEM Parts: Quality Assurance and Compatibility

What are OEM Parts?

OEM parts are manufactured by the same company that produced the cylindrical printer. These parts are designed to meet the exact specifications and quality standards of the original machine. This can inspire confidence in their performance and longevity.

Benefits of OEM Parts

·

Quality Assurance: OEM parts are made from high-quality materials and are thoroughly tested for reliability and performance.

·

·

Guaranteed Compatibility: Because they are designed specifically for your machine, OEM parts ensure a proper fit and seamless operation.

·

·

Warranty Protection: Using OEM parts often comes with a warranty that can cover potential damages or malfunctions, providing peace of mind.

·

·

Expert Support: OEMs typically have customer support teams who are knowledgeable about their products and can provide assistance when needed.

·

Challenges of OEM Parts

·

Higher Costs: One of the primary drawbacks of OEM parts is that they can be significantly more expensive than their third-party counterparts.

·

·

Limited Availability: Depending on your location and the specific printer model, obtaining OEM parts can sometimes be challenging if there are supply chain disruptions.

·

Third-Party Parts: Cost-Effective Alternatives

What are Third-Party Parts?

Third-party parts are manufactured by independent companies that are not affiliated with the original manufacturer of the cylindrical printer. These parts may not always adhere to the same standards or specifications as OEM parts.

Benefits of Third-Party Parts

·

Cost Savings: Third-party suppliers often offer more affordable pricing, making it easier for businesses to manage their budgets.

·

·

Wide Availability: Many third-party parts are widely available and can be sourced quickly, especially in locations where OEM parts might be difficult to find.

·

·

Diverse Options: The variety of third-party suppliers can lead to innovations and different product options that might enhance performance.

·

Challenges of Third-Party Parts

·

Quality Concerns: The quality of third-party parts can vary widely, and opting for cheaper alternatives may sometimes lead to performance issues.

·

·

Compatibility Issues: Not all third-party parts are designed to fit original machines perfectly, which can result in operational issues if the parts do not integrate properly.

·

·

Lack of Warranty: Many third-party parts do not come with warranties, potentially increasing costs if the parts fail and require replacement.

·

Comparing OEM and Third-Party Parts

Choosing between OEM and third-party parts involves several considerations. Below, we’ll compare these two options based on critical factors that can influence your decision.

1. Cost

While OEM parts generally come with a premium price tag, third-party options can help reduce costs. However, it is essential to balance cost with quality to avoid long-term expenditures due to failures or performance issues.

2. Availability

If you require immediate access to parts, third-party suppliers might be your best bet. On the other hand, OEM parts may be subject to longer lead times, particularly if they are not widely stocked.

3. Quality and Performance

OEM parts typically guarantee high quality due to their manufacturing standards. In contrast, third-party parts can vary, so researching suppliers and their products becomes essential to ensure acceptable performance standards.

4. Support and Service

When investing in OEM parts, you often gain access to better customer support and service options. Third-party suppliers may offer varying levels of support, so it’s beneficial to check reviews and testimonials before making a choice.

Making the Right Choice for Your Business

The decision between OEM and third-party cylindrical printer parts should be based on your specific business needs and operations. Here are some key points to guide your decision:

·

Assess your budget and analyze the long-term value of parts. Sometimes, investing in quality can save you money down the road.

·

·

Evaluate part availability in your area and consider the potential downtime if parts need to be ordered.

·

·

Research third-party suppliers thoroughly, including reviews, customer experiences, and product guarantees.

·

Moreover, maintaining a balanced approach between both options might be beneficial. For instance, using OEM parts for critical components while sourcing less critical parts from third-party suppliers can create a cost-effective hybrid strategy.

Conclusion

The choice between OEM and third-party cylindrical printer parts is a critical consideration for businesses looking to optimize efficiency, reduce costs, and maintain high-quality production. By understanding the pros and cons of each option, along with the unique needs of your operation, you can make a more informed decision. It's about finding a balance that suits your requirements, ensuring your cylindrical printing operations remain seamless and productive. For those seeking to invest in quality machines, explore our high-quality cylindrical printers here to elevate your custom printing solutions.

FAQ

What is the difference between OEM and third-party printer parts?

OEM parts are made by the original manufacturer, ensuring high quality and compatibility, while third-party parts are produced by independent companies, which can be more cost-effective but may vary in quality and compatibility.

Are third-party parts reliable for cylindrical printers?

Reliability varies with third-party parts; some may perform exceptionally well, while others might not meet quality standards. It’s essential to research suppliers and read reviews to ensure you’re choosing a reputable option.

Can using third-party parts void my printer warranty?

Using third-party parts could potentially void your warranty depending on the manufacturer’s policies. It's advisable to check your warranty terms before making a decision.

How can I ensure I’m choosing quality third-party parts?

To choose quality third-party parts, conduct thorough research on suppliers, look for customer reviews and testimonials, and ask for product guarantees or warranties.

What should I consider before purchasing printer parts?

Consider factors such as cost, availability, compatibility, quality, and the level of customer support when deciding whether to purchase OEM or third-party printer parts.