Cylindrical Printer Training Packages: What Should Be Included?

Introduction

In recent years, the demand for advanced printing solutions has surged, particularly in the realm of cylindrical printing. Businesses are recognizing the potential for customization and variety in their product offerings. However, to harness the full potential of cylindrical printing technology, proper training is essential. This blog will explore the key components that should be included in effective cylindrical printer training packages to ensure businesses and their employees can maximize their productivity and creativity.

Benefits of Comprehensive Training

Investing in a comprehensive training package for cylindrical printers is not just an expense; it’s a strategic move. Understanding the benefits can help stakeholders appreciate why such training is invaluable:

·

Improved Skillset: Workers are equipped with the necessary skills to operate printers efficiently.

·

·

Increased Productivity: Well-trained staff can complete tasks faster and with fewer errors.

·

·

Reduction in Downtime: Knowledge about troubleshooting and maintenance can minimize operational interruptions.

·

·

Enhanced Creativity: Familiarity with the technology allows employees to experiment and innovate.

·

Essential Features of Training Packages

Training packages should be designed holistically to encompass various aspects of cylindrical printing. Here are the fundamental components that should be included:

1. Equipment Operation

This is the core of any training program. Employees should learn about:

·

The different types of cylindrical printers and their specifications.

·

·

How to set up the equipment for different materials and products.

·

·

Understanding and using software that drives the printer.

·

2. Material Knowledge

Different materials require different handling and printing techniques. Training should cover:

·

Types of materials suitable for cylindrical printing (e.g., glass, metal, plastic).

·

·

Material preparation techniques, including cleaning and priming.

·

·

Understanding how different materials affect print quality and durability.

·

3. Print Design Techniques

Incorporating design elements into cylindrical printing is essential for appeal and branding. Training should focus on:

·

Basics of graphic design relevant to cylindrical printing.

·

·

Software tools (e.g., Adobe Illustrator, CAD programs) for creating designs.

·

·

Best practices for layout and color compatibility.

·

4. Troubleshooting and Maintenance

Technical difficulties can halt production and lead to frustration. It’s crucial to include:

·

Common issues and how to identify them early.

·

·

Prevention strategies for equipment wear and tear.

·

·

Routine maintenance schedules and best practices.

·

5. Quality Control Standards

Quality assurance is critical in printing. Training should entail:

·

Establishing benchmarks for print quality.

·

·

Techniques for inspecting prints and identifying defects.

·

·

Understanding customer requirements and feedback for continuous improvement.

·

Interactive and Practical Learning

Effective training goes beyond theoretical knowledge. Here are ways to enhance learning through practical application:

1. Hands-On Sessions

Providing practical sessions allows employees to apply what they’ve learned. Scheduling time for:

·

Real-world printing tasks using various printers.

·

·

Experimenting with different materials and designs.

·

2. Simulated Scenarios

Incorporating simulated scenarios into training fosters quick thinking and problem-solving. This can include:

·

Role-playing difficult customer requests for custom prints.

·

·

Solving common issues that might arise during a printing process.

·

3. Assessment and Feedback

Regular assessment ensures that employees grasp the material. Including:

·

Interactive quizzes and practical tests.

·

·

Constructive feedback sessions to address any weaknesses.

·

Continuous Learning and Support

The printing industry is constantly evolving, and so should the training. A robust package should provide:

·

Access to online resources and updates about the latest technology.

·

·

Opportunities for advanced training and specialization courses.

·

·

Support forums or groups for ongoing peer-to-peer learning.

·

Conclusion

In conclusion, investing in a cylindrical printer training package is a smart decision for businesses looking to innovate and stand out in competitive markets. By including components such as equipment operation, material knowledge, design techniques, troubleshooting, and ongoing support, organizations can equip their teams for success. This leads to improved productivity, higher-quality output, and ultimately, satisfied customers.

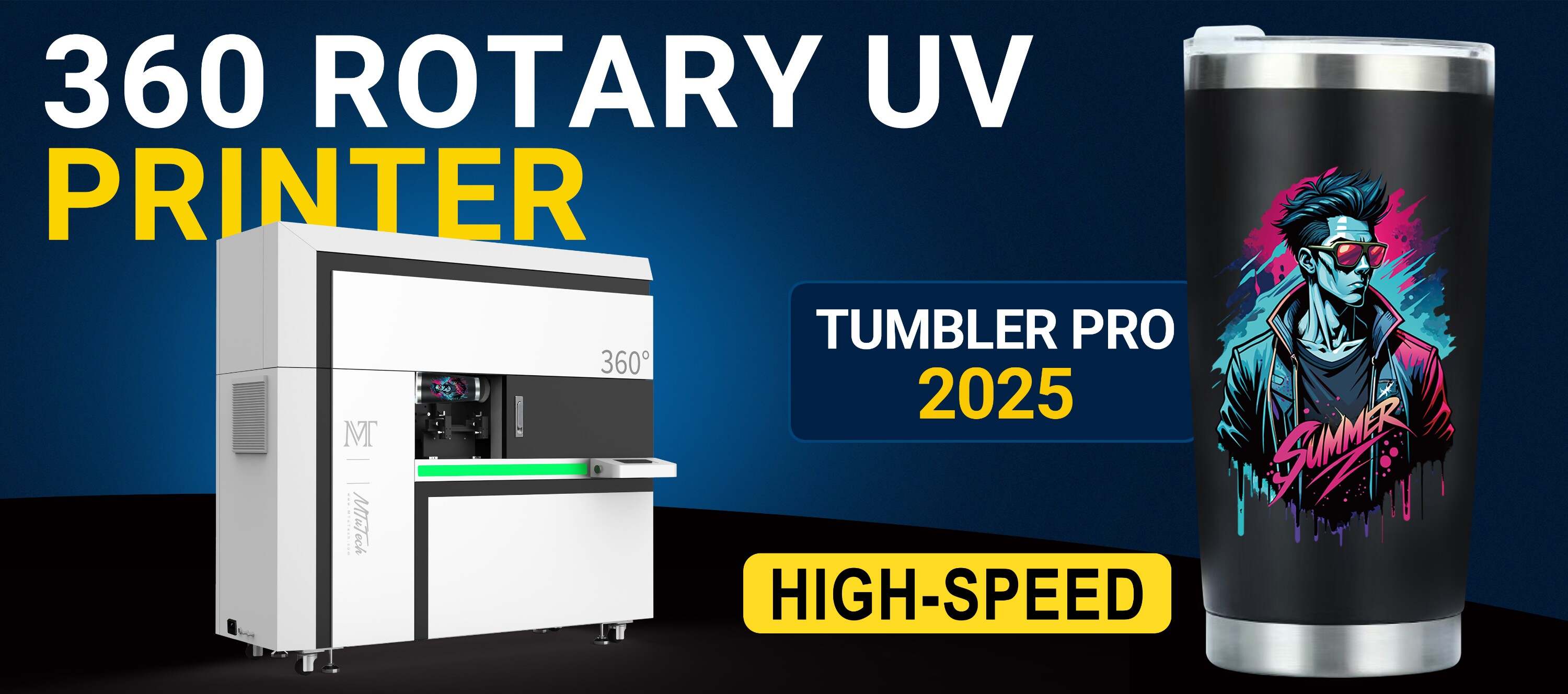

For anyone seeking to elevate their printing capabilities and explore high-quality options, explore our high-quality cylindrical printers here.

FAQ

What is a cylindrical printer?

A cylindrical printer is a specialized printing device designed to print on cylindrical objects like bottles, cans, and pens. They use advanced technologies such as UV printing and are capable of high-detail and colorful designs, making them popular in custom packaging and promotional items.

Why is training important for operating cylindrical printers?

Training is crucial for ensuring that operators can use the machines effectively and efficiently. Proper training minimizes mistakes, reduces machine downtime, enhances print quality, and fosters creative use of the printing technology.

How long does a typical cylindrical printer training package last?

Training durations can vary significantly based on the depth of content covered and the employees' prior experience. However, a comprehensive training program could range from a few days to several weeks, depending on both theoretical and practical components.

Can I customize the training package for my team's specific needs?

Yes, many training providers offer customizable packages. You can often select specific modules that best fit your team's current skill levels and the unique requirements of your business.

What are some common issues encountered while using cylindrical printers?

Common issues include misalignment during printing, ink smudging, material compatibility problems, and software or hardware malfunctions. Understanding these issues through training can significantly reduce occurrence and impact.