Cylindrical Printer Upgrade Paths: Modular vs Fixed Configuration

Introduction

In today's competitive market, businesses must continually adapt to meet their customers' needs. For those in the printing industry, this means evaluating the capabilities of their printing equipment. One crucial decision an organization must make is whether to opt for a modular or fixed configuration when considering an upgrade to their cylindrical printers. Both options offer distinct advantages, which we will explore in this article. Understanding these upgrade paths can help businesses choose the right configuration for their needs, enhancing productivity and ensuring long-term satisfaction.

Understanding Cylindrical Printers

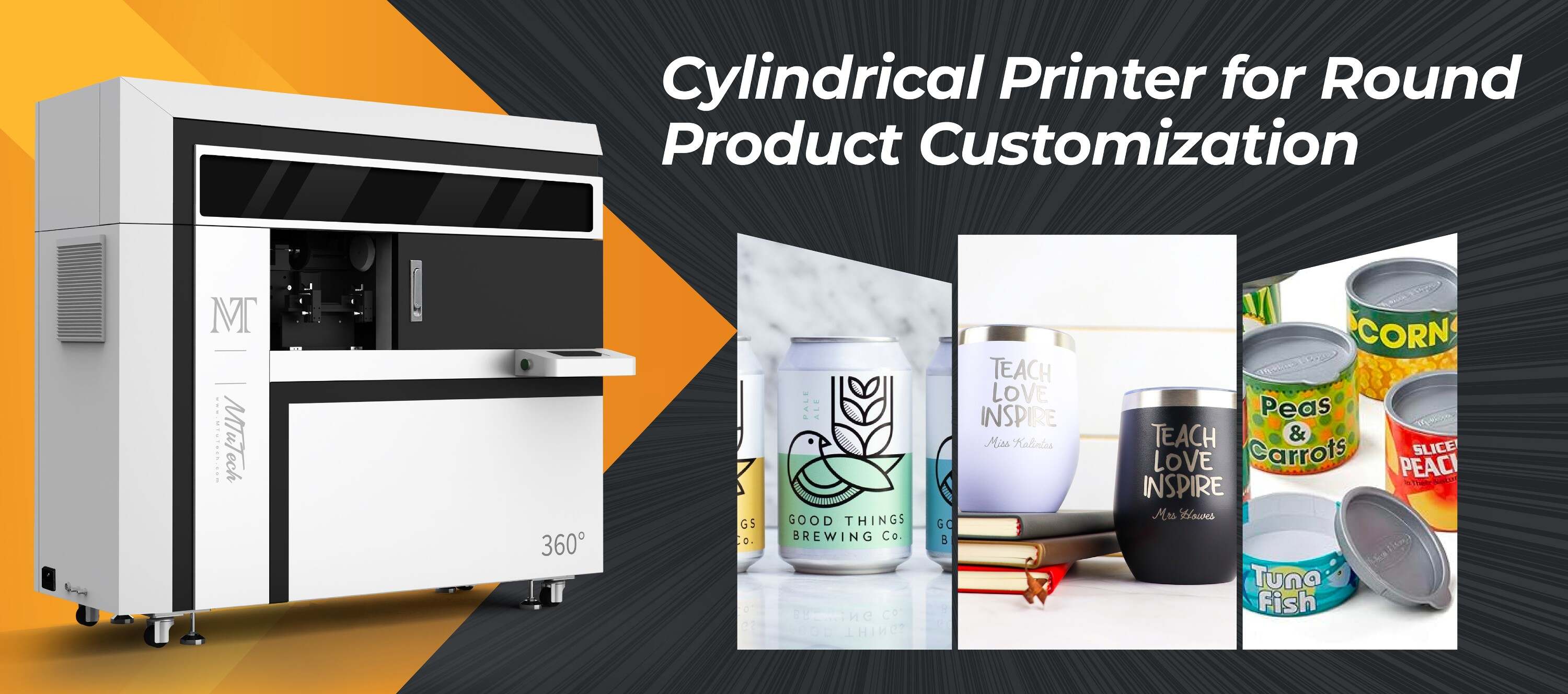

Cylindrical printers are specialized machines designed to print on round surfaces such as bottles, cans, and tubes. These printers have gained popularity due to their ability to produce high-quality graphics and text consistently. Manufacturers and suppliers focused on this niche market are continually innovating, leading to various configurations and features that businesses can leverage.

Fixed Configuration Cylindrical Printers

A fixed configuration cylindrical printer is typically a standalone machine with a defined set of capabilities. These printers are designed for specific applications and offer a streamlined approach to high-volume printing.

Features of Fixed Configuration Printers

·

Consistency: Fixed configuration printers provide reliable output quality, making them ideal for high-volume production.

·

·

Lower Initial Investment: These printers generally have lower upfront costs compared to modular printers.

·

·

Simplicity: Fixed configurations often require less training and technical expertise to operate effectively.

·

·

Space Efficiency: Fixed machines tend to have a smaller footprint, making them suitable for businesses with limited production space.

·

Limitations of Fixed Configuration Printers

·

Lack of Flexibility: Users are typically limited to the machine's original specifications, restricting adaptability to new projects or designs.

·

·

Upgrading Costs: Upgrades often necessitate the purchase of entirely new units, which can be costly and time-consuming.

·

Modular Configuration Cylindrical Printers

Modular configuration printers are designed with adaptability in mind, allowing businesses to customize and upgrade their machines as needed. This type of printer is made up of various independent modules that can be added, removed, or modified to enhance functionality.

Benefits of Modular Configuration Printers

·

Customization: Businesses can select the modules that cater specifically to their production needs, allowing for a tailored approach to printing.

·

·

Scalability: As business demands fluctuate, modular printers can be upgraded with additional modules to enhance capacity or functionality without replacing the entire unit.

·

·

Cost-Effectiveness: Instead of a massive upfront investment, companies can progressively upgrade their machines as budgets allow.

·

·

Longevity: Modular systems can evolve with changing technologies, ensuring long-term relevance and productivity.

·

Challenges of Modular Configuration Printers

·

Higher Initial Setup Complexity: The flexibility of modular printers can lead to more complicated initial setups, requiring higher expertise during installation.

·

·

Maintenance Considerations: With more components and modules, maintenance can become more complex and require specialized knowledge.

·

Comparing the Two Configurations

When deciding between a modular and a fixed configuration cylindrical printer, it's crucial to consider the specific needs of your business as well as your long-term goals. Here’s a breakdown of factors to evaluate.

Cost

Fixed configuration printers generally have lower initial costs, making them an attractive option for startups or businesses with tight budgets. However, modular printers, while potentially more expensive to set up initially, can be more cost-effective in the long run due to their adaptability and ease of upgrades.

Flexibility and Customization

For businesses that expect to diversify their product range or anticipate growing demand, modular printers offer distinctive advantages. The ability to customize modules means companies can respond swiftly to market changes without having to replace their entire equipment.

Production Volume and Speed

If your business operates on high-volume production requirements, fixed configuration printers may provide the speed and efficiency necessary for seamless operations. However, modular printers can offer speed enhancements through additional printing heads or specialized modules, allowing increased productivity as needed.

Technology and Features

As printing technologies evolve, the challenge is to keep pace with the latest developments. Modular systems tend to be more future-proof, as businesses can upgrade their machines to incorporate new technologies without having to invest in a completely new unit.

Choosing the Right Path for Your Business

Ultimately, the decision between a modular or fixed configuration cylindrical printer depends on various factors unique to your business. Here are some key points to consider:

·

Current and Future Production Needs: Assess if your current needs align with fixed configuration capabilities or if you foresee expanding your product line which would favor a modular option.

·

·

Budget Constraints: Analyze your financial situation, keeping in mind both initial costs and long-term operational expenses.

·

·

Space Considerations: Evaluate your production floor plan to determine which printer fits best.

·

·

Technical Expertise: Determine the level of training and support you have available for operating complex systems.

·

Conclusion

Both modular and fixed configuration cylindrical printers offer unique advantages that cater to different business requirements. By carefully evaluating your production needs, budget, and long-term goals, you can make an informed decision that sets your business up for success. If you’re ready to enhance your printing capabilities, explore our high-quality cylindrical printers here and find the perfect solution tailored to your specific needs.

FAQ

What types of materials can be printed using cylindrical printers?

Cylindrical printers can print on a wide variety of materials, including plastic, glass, metal, and paper. This versatility makes them suitable for a range of products, including bottles, jars, and cans.

What is the average cost difference between modular and fixed configuration printers?

The average cost difference can vary widely based on the manufacturer and the features of the machines. Generally, fixed configuration printers can range from $10,000 to $50,000, while modular printers may start at $20,000 and can exceed $100,000 depending on the selected modules and functionalities.

How can I determine the best configuration for my specific needs?

Start by evaluating your production volume, desired customization, budget constraints, and future growth expectations. Consulting with a printing solution expert can also provide insights tailored to your specific business scenario.

What kind of training is required to operate modular printers?

Modular printers may require more specialized training due to their complexity. Companies often provide training sessions or workshops for operators to familiarize themselves with the customization options and various modules of the printer.

Can I retrofit a fixed configuration printer to make it modular?

While it is generally challenging to retrofit fixed configuration printers to become modular, some manufacturers may offer upgrade kits or parts to enhance functionality. However, this process may not provide the same flexibility as investing in a modular printer from the start.