Cylindrical Printing for Brewery and Beverage Industries

Introduction

In the dynamic world of the brewery and beverage industries, standing out on the shelves is more critical than ever. Cylindrical printing has emerged as a powerful solution to create eye-catching labels, containers, and branding materials that resonate with consumers. This innovative printing technology not only enhances product appeal but also aligns with the rapid advancements in packaging design and sustainability.

What is Cylindrical Printing?

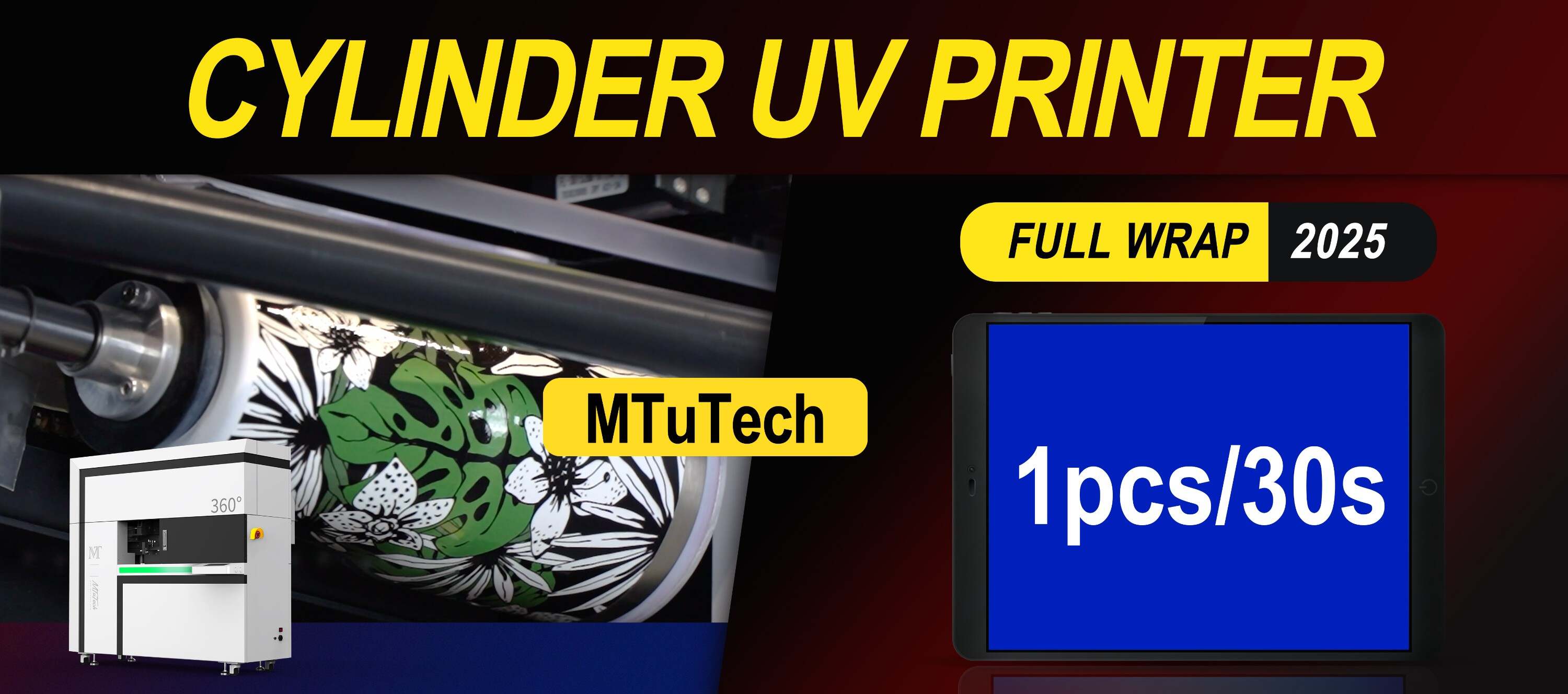

Cylindrical printing refers to the process of applying designs onto cylindrical objects such as bottles, cans, and barrels. This method enables 360-degree printing, ensuring that artwork covers the entirety of the surface area, making it visually appealing from any angle. With the rise of craft breweries and beverage brands, cylindrical printing has become an essential tool for packaging design, delivering vibrant colors and intricate details.

Benefits of Cylindrical Printing

The adoption of cylindrical printing within the brewery and beverage industries comes with numerous benefits that can enhance branding efforts and improve product visibility.

1. Enhanced Visual Appeal

Cylindrical printing allows for full-color, high-resolution designs that can capture the essence of the brand. Consumers are often drawn to products that stand out on the shelf, making captivating visuals essential.

2. Versatility in Packaging

This type of printing can be applied to a variety of materials, including glass, plastic, and metal. This versatility allows manufacturers to choose the most suitable packaging for their products without compromising on design integrity.

3. Branding Opportunities

Your product label is often the first interaction a consumer has with your brand. Cylindrical printing enables businesses to create unique branding opportunities, from beer labels to promotional containers, helping to convey the brand story effectively.

4. Environmentally Friendly Options

Many modern cylindrical printers utilize eco-friendly inks and technologies, enabling companies to adopt sustainable practices. As consumers increasingly prefer environmentally responsible products, this can give breweries a competitive edge.

5. Cost-Effectiveness

While initial investments may seem significant, cylindrical printing can ultimately save money in the long run. It allows for small batch runs without the need for extensive setup changes, enabling breweries to experiment with limited-edition flavors and designs.

Features of Cylindrical Printing Solutions

Modern cylindrical printing solutions come equipped with advanced features that elevate printing capabilities and ensure high-quality results. Here are some of the key features to consider:

1. High-Speed Printing

Efficiency is crucial in any production process. Advanced cylindrical printers are designed to operate at high speeds, enabling breweries to meet growing demand without sacrificing quality.

2. Customization Options

Customization is key in the craft beverage market. Cylindrical printing allows for intricate designs, texts, and graphics to be fully tailored to the brand's vision, ensuring that no two products are the same.

3. Digital Technology Integration

Many cylindrical printing solutions now incorporate digital technologies, allowing for precise color matching and quick adjustments during the printing process. This digital integration enhances overall production efficiency and minimizes errors.

4. Minimal Waste Production

Efficient ink utilization and the ability to print on demand lead to minimal waste in cylindrical printing, making it a sustainable choice for businesses looking to reduce their environmental impact.

5. User-Friendly Interfaces

Modern cylindrical printers often come equipped with intuitive interfaces that simplify the operation process, reducing the need for extensive training and allowing operators to focus on creativity and production.

Challenges in Cylindrical Printing

While cylindrical printing offers many benefits, it is not without challenges. Understanding these challenges can help breweries effectively navigate potential issues:

·

Initial Investment: High-quality cylindrical printers can require substantial upfront investments that may be daunting for small businesses.

·

·

Material Compatibility: Not all materials perform equally well in cylindrical printing, necessitating testing and adaptation.

·

·

Technical Knowledge: Operators should possess a skill set that combines art with technology, as precision is vital in producing high-quality prints.

·

Best Practices for Implementing Cylindrical Printing

To maximize the benefits of cylindrical printing, breweries should adopt best practices that streamline the process and enhance product appeal:

·

Invest in Quality Materials: Select high-quality inks and substrates to ensure durability and vibrant colors.

·

·

Train Your Team: Provide comprehensive training to staff to operate the machinery efficiently and ensure high-quality output.

·

·

Embrace Design Innovation: Regularly update your designs to align with market trends and consumer preferences, allowing your brand to remain relevant.

·

·

Focus on Sustainability: Choose eco-friendly options whenever possible to appeal to environmentally conscious consumers.

·

·

Collaborate with Experts: Working with experienced printers can provide insights and improve the overall quality of production.

·

Conclusion

Cylindrical printing is revolutionizing the way breweries and beverage companies approach packaging. By leveraging this innovative technology, businesses can enhance their brand presence, appeal to consumers, and embrace sustainability. With its myriad of benefits, cylindrical printing remains an invaluable asset in the competitive marketplace. If you’re looking to elevate your branding with cutting-edge technology, consider investing in cylindrical printing solutions.

For those interested in exploring state-of-the-art cylindrical printing options, explore our high-quality Cylindrical printers here.

FAQ

What types of products can be printed using cylindrical printing?

Cylindrical printing is ideal for various products such as beer bottles, soda cans, and other beverage containers, allowing brands to create striking designs and labels.

Is cylindrical printing environmentally friendly?

Many modern cylindrical printing solutions utilize eco-friendly inks and reduce waste through efficient ink utilization, making them suitable for environmentally conscious practices.

How does cylindrical printing compare to traditional label printing?

Cylindrical printing offers 360-degree coverage and high-resolution designs, whereas traditional label printing may limit design options and placement on surfaces.

Can I customize designs for limited beer releases?

Absolutely! Cylindrical printing supports customization, making it perfect for limited edition or seasonal releases, ensuring that each design can be unique.

What should I consider when choosing a cylindrical printer?

Consider factors such as the types of materials you need to print on, the speed of production, customization capabilities, and eco-friendliness when selecting a cylindrical printer.