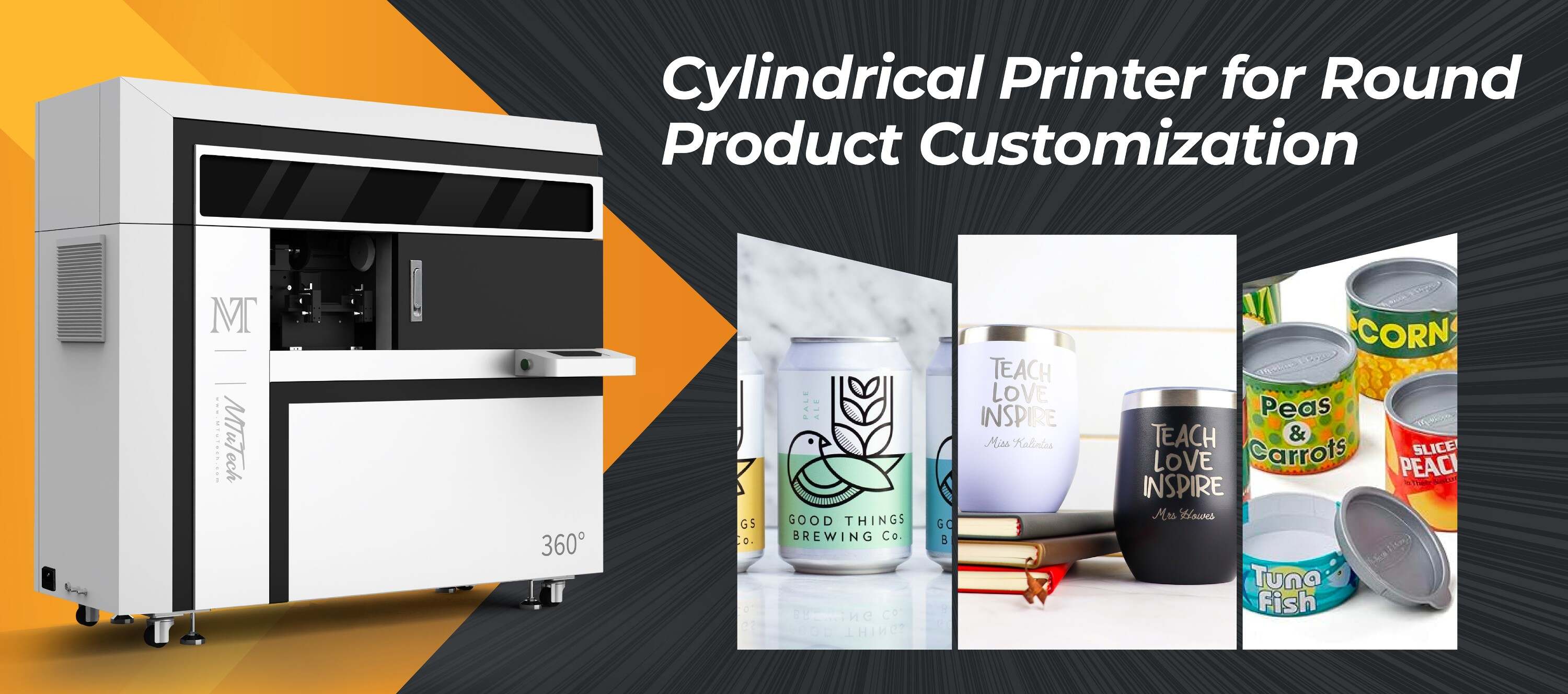

Cylindrical Printing for Fast-Moving Consumer Goods (FMCG)

Introduction

In the competitive world of fast-moving consumer goods (FMCG), brands are constantly seeking innovative ways to differentiate themselves from competitors. One such innovation that has made waves recently is cylindrical printing. This technique offers unique advantages that cater to the needs of FMCG companies, particularly in terms of packaging and branding. In this article, we will explore the benefits and features of cylindrical printing and how it can revolutionize the FMCG industry.

Understanding Cylindrical Printing

Cylindrical printing is a specialized printing technique used primarily for decorating cylindrical objects—such as bottles, cans, and tubes—commonly found in FMCG packaging. Traditional printing methods often fall short when it comes to achieving high quality on these shapes, but cylindrical printing overcomes these hurdles with precision and efficiency.

Why Is It Important for FMCG?

The FMCG sector is characterized by high competition and fast turnover of products. Packaging plays a crucial role in attracting consumers and influencing purchase decisions. Here are a few reasons why cylindrical printing is essential:

·

Brand Visibility: Eye-catching designs on cylindrical packaging can stand out on crowded shelves.

·

·

Customization: Brands can easily create unique aesthetics that align with their marketing strategies.

·

·

Durability: Cylindrical printing often uses UV-resistant inks, ensuring that colors remain vibrant despite exposure to light.

·

Benefits of Cylindrical Printing for FMCG

Adopting cylindrical printing can produce a range of benefits for FMCG brands. Let’s delve into some of the key advantages.

1. High-Quality Prints

Cylindrical printing delivers exceptional print quality, which is critical for capturing consumer attention. Advanced printing technology ensures that colors are vibrant and details are sharp, enhancing the overall presentation of the product.

2. Versatility

This printing method is incredibly versatile, able to print on a wide array of materials, including glass, plastic, and metal. This adaptability makes it suitable for various FMCG products such as beverages, cosmetics, and household cleaning items.

3. Speed and Efficiency

Time is money in the FMCG sector. Cylindrical printing processes are designed for high-speed production, allowing brands to bring their products to market quickly without compromising on quality.

4. Cost-Effective Printing Solutions

Although the initial investment in cylindrical printing technology may seem high, the long-term savings in terms of reduced waste and faster production times can significantly lower overall costs. Brands benefit from lower maintenance and operational costs compared to traditional printing methods.

5. Sustainable Practices

Sustainability is becoming increasingly important to consumers. Many cylindrical printing technologies utilize eco-friendly inks and materials, aligning with the growing demand for sustainable products in the FMCG sector.

Key Features of Cylindrical Printing Technology

Cylindrical printing has several features that set it apart from traditional printing methods. Understanding these features can help FMCG companies to better leverage this technology.

Automated Workflow

Many cylindrical printers feature automated workflows that streamline the printing process. This automation minimizes the risk of human error and increases production speed—an important factor in an industry where quick turnaround times are essential.

Printing on Various Substrates

From shrink sleeves to direct printing on complex shapes, cylindrical printing accommodates a range of substrate materials and shapes. This flexibility allows for intricate designs and creative branding solutions.

Integration with Digital Technology

Modern cylindrical printers often integrate with digital technologies, allowing for on-demand printing. This means companies can make last-minute changes to designs without the need for expensive and time-consuming setup processes.

Customizable Graphics

The ability to create customized graphics in real-time is one of the standout features of cylindrical printing. Whether changing logos, colors, or designs, FMCG brands can adapt to market trends and consumer preferences quickly.

End-to-End Solutions

Some cylindrical printing solutions offer end-to-end services, meaning they can handle everything from design to printing and packaging. This can be particularly advantageous for FMCG brands looking to simplify their supply chain management.

Applications of Cylindrical Printing in FMCG

The applications for cylindrical printing within FMCG are vast. Here are a few notable examples:

Beverage Packaging

From soda cans to water bottles, cylindrical printing excels in creating vibrant, captivating labels that promote brand identity effectively. Beverage companies can enhance their visibility and communicate their brand message through striking graphical designs.

Cosmetic and Personal Care Products

Many cosmetic brands use cylindrical packaging for products like lipsticks and creams. The ability to print intricate designs and logos helps reinforce brand prestige and image, appealing directly to consumer aesthetics.

Household Goods

Everyday items like cleaning products and soaps can benefit from customized cylindrical printing. A well-designed label can communicate important product information while enhancing shelf presence.

Challenges and Considerations

While cylindrical printing offers numerous benefits, there are also challenges and considerations FMCG brands should keep in mind. These include:

·

Initial Investment: The cost of acquiring cylindrical printing technology can be significant, especially for smaller brands.

·

·

Training Needs: Employees may require specialized training to operate advanced printing machines effectively.

·

·

Design Complexity: While customization is a strength, overly complex designs may lead to production inconsistencies or errors.

·

Conclusion

Cylindrical printing stands poised as a game-changer in the FMCG industry, offering high-quality, versatile, and efficient solutions that cater to the ever-evolving needs of brands. By enhancing visibility, allowing for customization, and embracing sustainability, cylindrical printing can help FMCG companies spend less time worrying about the packaging and more on what matters—connecting with their consumers. Explore our high-quality Cylindrical printers here to see how you can elevate your branding efforts today.

FAQ

What types of products are suitable for cylindrical printing?

Cylindrical printing is ideal for a range of products, including beverage containers, cosmetic packaging, and household goods. It is particularly effective on cylindrical surfaces such as bottles, cans, and tubes.

How does cylindrical printing differ from traditional printing methods?

Cylindrical printing utilizes specialized technology designed for curved surfaces, allowing for higher quality prints, adaptability to various substrates, and faster production speeds compared to traditional flat printing methods.

Is cylindrical printing environmentally friendly?

Yes, many modern cylindrical printing techniques use eco-friendly inks and materials, making them a more sustainable choice for brands looking to reduce their carbon footprint.

What are the costs associated with cylindrical printing?

While the upfront investment in cylindrical printing technology can be higher than traditional methods, cost savings may be realized through increased efficiency, reduced waste, and faster turnaround times.

Can I customize designs in cylindrical printing?

Absolutely! One of the primary benefits of cylindrical printing is the ability to quickly customize designs and graphics, allowing brands to adapt to market trends and consumer preferences easily.