Cylindrical Printing for Kids’ Products: Safety and Compliance

Cylindrical Printing for Kids’ Products: Safety and Compliance

Introduction

In today’s consumer-driven market, the demand for customized and eye-catching children's products is skyrocketing. As manufacturers explore innovative ways to attract young audiences, cylindrical printing has emerged as a popular solution. This printing technique not only enhances the aesthetic appeal of products but also raises important questions about safety and compliance. In this blog post, we will dive deep into cylindrical printing, especially concerning its application in kids' products.

Understanding Cylindrical Printing

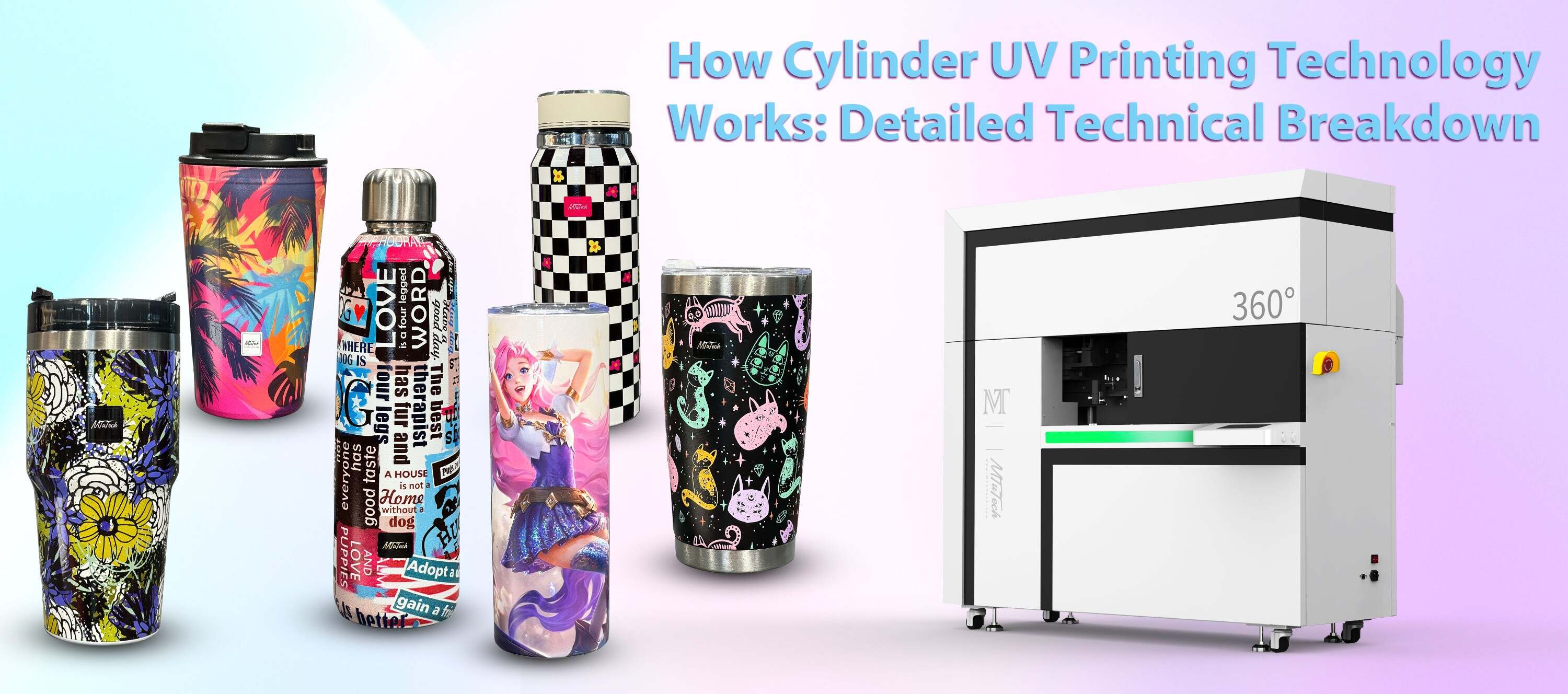

Cylindrical printing refers to the process of printing on cylindrical objects using specialized printers that can wrap designs around various surfaces seamlessly. It is especially popular for items like bottles, cups, and toys. The primary advantage of cylindrical printing lies in its ability to offer full-color designs that can wrap around the entirety of the product. This capability not only improves visual appeal but also enhances branding opportunities for manufacturers.

Benefits of Cylindrical Printing in Children’s Products

Enhanced Aesthetic Appeal

Cylindrical printing allows for vibrant and complex designs that capture children's attention. This feature is crucial when competing for shelf space in stores or online marketplaces. Bright colors, unique patterns, and engaging characters can transform mundane products into exciting, must-have items for kids.

Customization Opportunities

The flexibility of cylindrical printing enables manufacturers to offer customization options. Personalizing a product — for example, a cups with a child’s name or a unique design — can boost emotional attachment and encourage sales. Customization not only leads to greater consumer satisfaction but also allows brands to cater to niche markets.

Durability of Prints

One of the significant advantages of cylindrical printing is the longevity of the printed designs. Unlike traditional printing methods, which can wear off or fade, cylindrical printing uses UV-curable inks that are resistant to scratches, fading, and water damage. This durability is particularly beneficial for kids’ products, which are often subjected to rigorous use.

Safety Considerations for Kids’ Products

When it comes to children's products, safety is a non-negotiable priority. Here are some essential considerations regarding the safety and compliance of cylindrical printing:

Non-Toxic Materials

Printed materials used in children's products must comply with safety regulations regarding toxicity. Manufacturers should ensure that the inks used in cylindrical printing are free from harmful chemicals, such as lead and phthalates. It's advisable to choose inks that are made from eco-friendly, non-toxic materials.

Compliance with Safety Standards

Regulatory bodies like the Consumer Product Safety Commission (CPSC) and the American Society for Testing and Materials (ASTM) set stringent standards for children’s products. Manufacturers must ensure that their cylindrical printing processes adhere to these standards, which may include:

·

Thorough testing for chemical composition

·

·

Regular audits to ensure compliance

·

·

Certification of materials used in production

·

Durability and Child Resistance

Aside from chemical safety, the physical durability of printed products is imperative. Cylindrical prints should not easily chip or fade, and children’s products should be designed with safe edges and structures that are resistant to breakage. This durability ensures that products can withstand the wear and tear associated with children's play.

Age Appropriateness

Safety also includes ensuring that products are age-appropriate. Toys and products targeted at younger children should have additional safety measures, such as break-proof materials and designs that prevent choking hazards. Understanding the appropriate age range for a product helps manufacturers tailor their cylindrical printing accordingly, avoiding potential safety issues.

Environmental Considerations

Another crucial aspect of manufacturing children’s products through cylindrical printing is the environmental impact. As consumers become more eco-conscious, businesses must align their production methods with sustainability goals.

Sustainable Inks and Materials

Using water-based inks and recyclable materials can significantly reduce the environmental footprint of products. In addition, manufacturers should look for suppliers who offer eco-friendly cylindrical printing options, ensuring that they contribute to a more sustainable future.

Waste Management Practices

Efficient waste management practices reduce the adverse environmental impact of production. This includes recycling any excess materials generated during the cylindrical printing process and ensuring that hazardous waste is handled and disposed of correctly.

Choosing the Right Partner for Cylindrical Printing

Selecting the right printing partner is essential for ensuring the safety and compliance of your kids’ products. Here are key factors to consider:

Experience and Expertise

Look for a printing company with extensive experience in cylindrical printing, particularly in the children’s product sector. Knowledge of compliance and safety regulations is paramount, as they will better navigate the complexities involved in production.

Quality Assurance Processes

Ensure that the company has a robust quality assurance process in place. This can include regular testing of materials and ongoing inspections during the production process, ensuring the final product meets safety standards.

Transparency and Communication

A reliable printing partner should maintain open lines of communication, providing you with all necessary documentation regarding safety compliance and materials used. Transparency is a vital component of a trustworthy relationship.

Conclusion

In conclusion, cylindrical printing offers exciting opportunities for creating vibrant and engaging products aimed at children. However, manufacturers must prioritize safety and compliance to ensure the well-being of their young consumers. By choosing non-toxic materials, adhering to regulatory standards, and implementing sustainable practices, businesses can thrive while maintaining a reputation for safety and quality. If you are exploring cylindrical printing options, explore our high-quality cylindrical printers here to find robust solutions for your manufacturing needs.

FAQ

What is cylindrical printing used for in kids’ products?

Cylindrical printing is primarily used for decorating cylindrical objects like bottles, cups, and toys. It enhances the visual appeal and offers customization options that attract young consumers.

Are the inks used in cylindrical printing safe for children?

When selecting cylindrical printing services, it’s crucial to confirm that non-toxic, eco-friendly inks are used. Manufacturers should ensure compliance with safety regulations regarding chemical compositions.

How can manufacturers ensure safety compliance in cylindrical printing?

Manufacturers can ensure safety compliance by following established safety standards, conducting regular materials testing, and using certified suppliers for inks and materials.

What are some best practices for sustainable cylindrical printing?

Best practices for sustainable cylindrical printing include using water-based inks, recycling materials, and implementing waste management processes to minimize environmental impact.

How can I choose a reliable printing partner for kids’ products?

Look for a partner with experience in cylindrical printing for children’s products, solid quality assurance processes, and a commitment to transparency and open communication regarding safety compliance.