Design Tools for Efficient Cylinder UV Print Workflow

Introduction

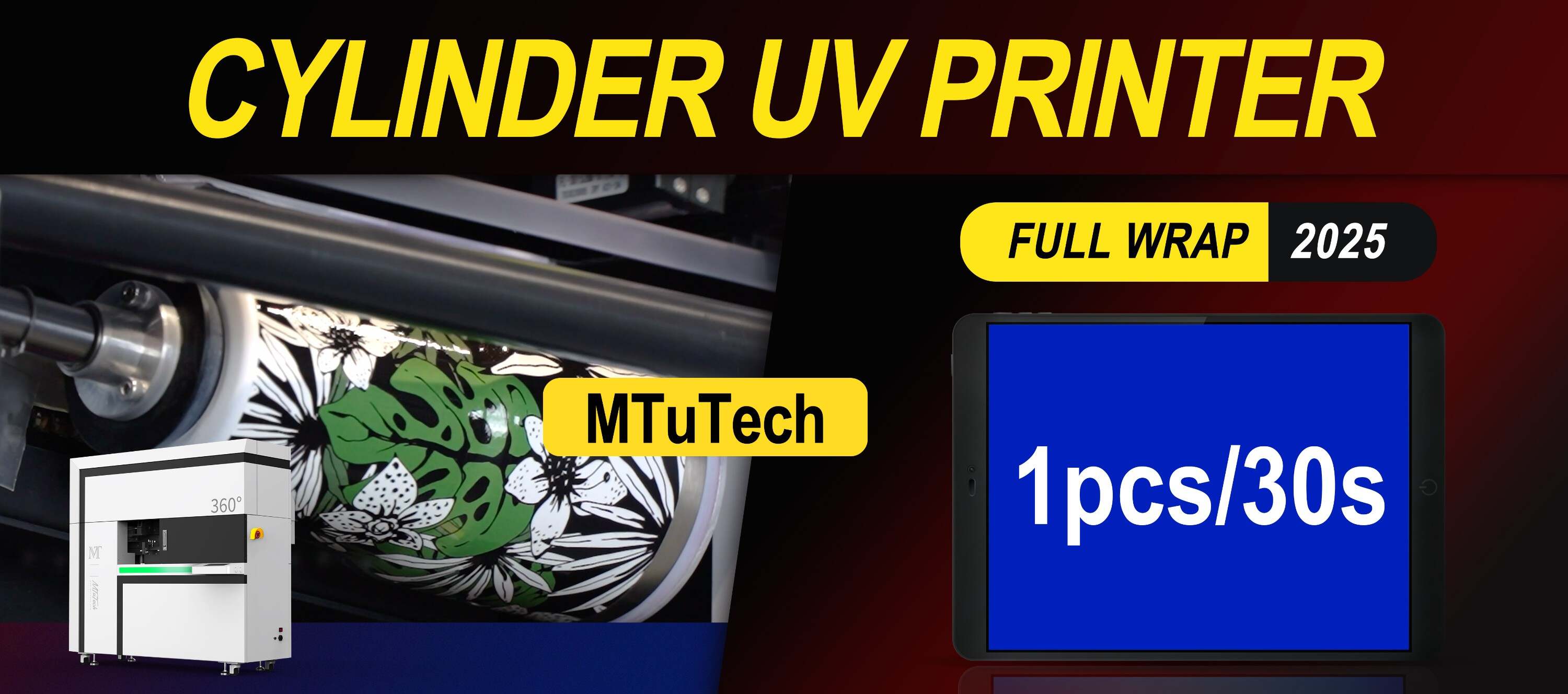

In today’s fast-paced printing industry, the demand for high-quality, efficient, and versatile printing solutions has never been greater. Cylinder UV printing, in particular, has emerged as a game-changer, allowing businesses to produce vivid prints on a variety of cylindrical surfaces. However, to leverage the full potential of cylinder UV printing, an efficient workflow is essential. This is where the right design tools come into play. In this blog post, we will explore the various design tools that enhance the cylinder UV print workflow, allowing for improved efficiency and superior print quality.

Understanding Cylinder UV Printing

Cylinder UV printing is a specialized printing method that uses ultraviolet light to cure or dry ink as it is printed. This technology enables prints to be applied to a wide range of surfaces, such as glass, plastic, metal, and more, making it ideal for packaging, marketing materials, and product customization. The advantages of cylinder UV printing include:

·

Rapid curing times, allowing for faster turnaround on projects.

·

·

Vivid colors and high-quality finishes.

·

·

Durability and resistance to fading and scratching.

·

·

Environmentally friendly options with reduced VOC emissions.

·

Essential Design Tools for Cylinder UV Printing

To ensure a seamless cylinder UV print workflow, it is crucial to utilize the best design tools available. Let’s take a closer look at some essential tools that can significantly enhance your process.

1. Vector Design Software

Vector design software is invaluable for creating scalable graphics without losing quality. This is particularly important in cylinder printing, where designs need to wrap seamlessly around curved surfaces. Some popular vector design software options include:

·

Adobe Illustrator: Widely regarded as the industry standard, this powerful tool offers advanced features for vector creation and manipulation.

·

·

CorelDRAW: This is another popular choice among designers, offering robust tools for vector graphics and typography.

·

·

Inkscape: A free alternative to the above options, Inkscape provides essential vector design capabilities suitable for printing projects.

·

2. 3D Modeling Software

When dealing with three-dimensional objects, 3D modeling software becomes essential. This software allows designers to visualize how their graphics will appear on cylindrical surfaces. Recommended options are:

·

Autodesk Fusion 360: This is an intuitive platform that combines parametric design, sculpting, and mesh modeling capabilities.

·

·

SketchUp: Known for its user-friendly interface, SketchUp is good for quick mock-ups and basic shape modeling.

·

3. RIP Software

RIP (Raster Image Processor) software plays a critical role in converting design files into printable formats. It optimizes the color separation and print layout, ensuring that the final output matches the design intent. Popular RIP software includes:

·

Wasatch SoftRIP: Known for its robust features and compatibility with various printers, this software allows for extensive color management options.

·

·

SAi Flexi: A comprehensive solution that combines design and RIP functions, enabling seamless workflows from design to output.

·

4. Color Management Tools

Ensuring accurate color reproduction is vital in UV printing. Color management tools help maintain color consistency across different devices and media. Key tools in this area include:

·

Calibrated Monitors: Use high-quality, color-calibrated monitors for accurate color previews before printing.

·

·

Color Profiles: Incorporate ICC profiles that match your printer and ink combinations to achieve the desired results.

·

Workflow Integration

The design tools mentioned above are powerful on their own, but their true potential is unlocked when they are integrated into a cohesive workflow. Here’s how to ensure effective workflow integration:

1. File Preparation

Before printing, ensure that your files are correctly prepared. This involves:

·

Checking for resolution and color mode suitability.

·

·

Converting text to outlines to avoid font issues.

·

·

Verifying dimensions and layout against the actual dimensions of the cylindrical object.

·

2. Prototyping

Utilizing 3D modeling and vector design tools, create prototypes of the printed product. Use mock-ups to visualize how the final print will look on the cylinder. This step is essential for identifying potential design flaws before going into production.

3. Collaborative Design

Involve your entire team in the design process. Use collaboration tools such as:

·

Adobe Creative Cloud: Allows team members to share designs and work on projects simultaneously.

·

·

Trello or Asana: Project management tools that help keep everyone on track and maintain transparency in the workflow.

·

4. Feedback and Iteration

Establish a feedback loop to refine designs based on team input and client requirements. Iterative design is key to achieving the best results, especially when working with clients who have specific expectations for their products.

Conclusion

Designing for cylinder UV printing requires a combination of creativity, technical skill, and the right tools. By integrating vector design software, 3D modeling tools, efficient RIP software, and robust color management solutions into your workflow, you can significantly enhance the efficiency and quality of your printing process. The market for cylinder UV printing continues to grow, and being equipped with the right design tools can provide a competitive edge. To explore even more about high-quality cylinder UV printing solutions, explore our high-quality Cylinder UV printers here.

FAQ

What is the primary benefit of using cylinder UV printing?

The primary benefit of cylinder UV printing is the ability to print on a wide range of substrates, including materials that are typically challenging to print on, such as glass and metal, while providing vibrant colors and quick curing times.

Which design software is best for beginners in cylinder UV printing?

For beginners, Inkscape is a great option as it is free and offers a variety of vector design tools. Adobe Illustrator is another excellent option, though it requires a subscription.

How can I ensure my colors are consistent across various prints?

Using ICC color profiles specific to your printer and ink combinations is essential for maintaining color consistency. Regular calibration of monitors and printers will also help ensure color accuracy.

What should I consider when choosing RIP software for cylinder UV printing?

When selecting RIP software, consider factors such as compatibility with your printer, available color management tools, ease of use, and the ability to handle complex files. Software like Wasatch SoftRIP and SAi Flexi are popular choices in the industry.

Can I create prototypes before the final print?

Yes, creating prototypes is an important step in the design process. You can use 3D modeling software to visualize how the graphics will look on the cylindrical object before going into production.