How Cylindrical Printing Is Changing Beverage Packaging Design

Introduction

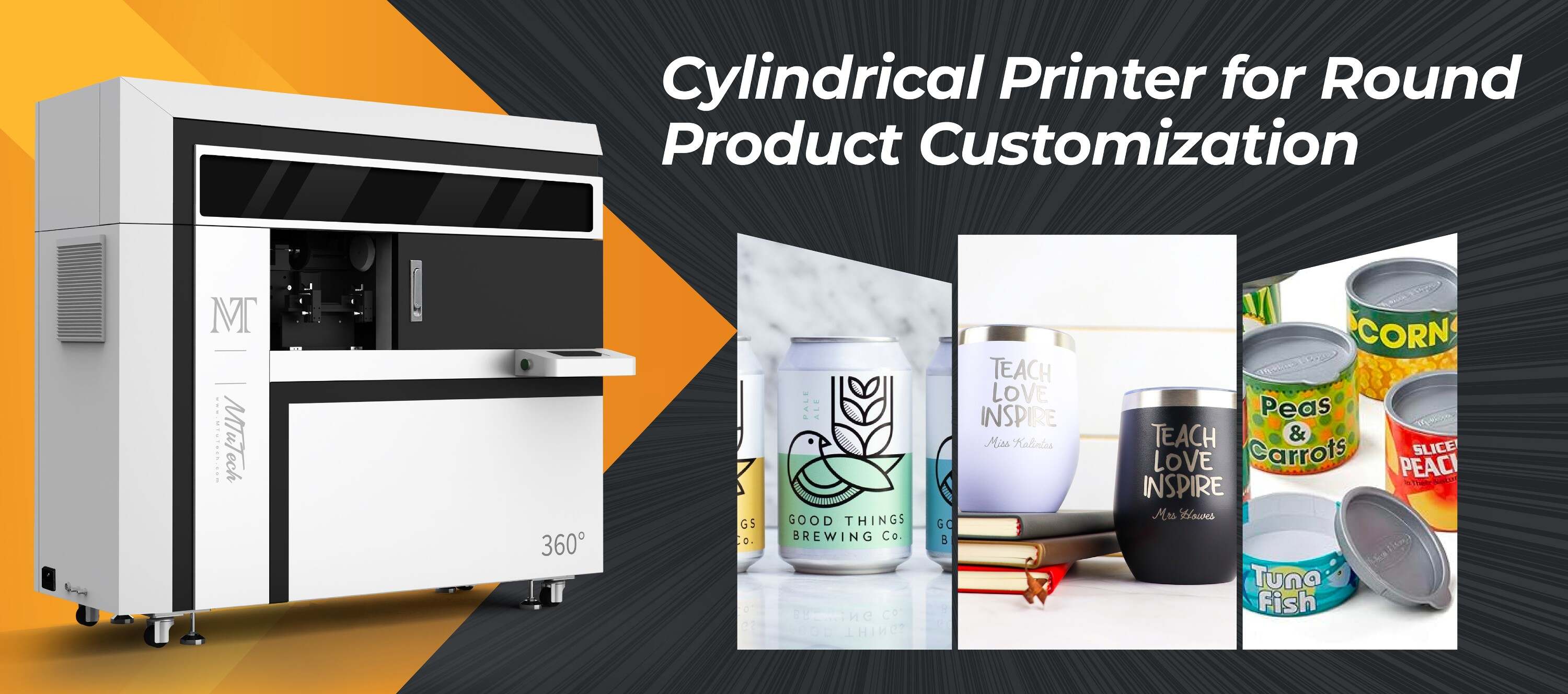

In the ever-competitive beverage industry, the pursuit of innovative packaging design has taken center stage. A standout in this arena is cylindrical printing, a revolutionary method that is reshaping how beverages are packaged. Unlike traditional flat printing, cylindrical printing utilizes the full three-dimensional surface of bottles and cans, allowing for unique visual storytelling and brand representation.

The Evolution of Beverage Packaging

Traditionally, beverage packaging relied heavily on flat labels, which limited the design possibilities and often resulted in a less engaging product appearance. As consumers increasingly seek visually appealing products, brands are realizing the importance of standing out on crowded retail shelves.

Cylindrical printing has emerged as a game-changer, enabling brands to utilize the entire surface area of their containers. This technique not only enhances aesthetic appeal but also facilitates a more cohesive brand narrative. Let’s explore how cylindrical printing is revolutionizing beverage packaging design.

Benefits of Cylindrical Printing

1. Enhanced Visual Appeal

With cylindrical printing, brands can create stunning graphics that wrap seamlessly around the product. This capability leads to:

·

Vivid colors and intricate designs that attract customers.

·

·

3D effects that create depth and interest.

·

·

The ability to convey stories and brand values across the entire surface area.

·

2. Improved Brand Recognition

Brand recognition is critical, especially in a marketplace filled with competing options. The curved surfaces of beverage containers allow for:

·

Unique shapes that differentiate products.

·

·

Consistent branding across various formats and sizes.

·

·

Enhanced visibility from multiple angles, increasing the chances of consumer engagement.

·

3. Sustainable Packaging Options

As consumers increasingly prioritize sustainability, cylindrical printing offers brands a chance to highlight environmentally friendly practices. Benefits include:

·

Utilizing eco-friendly inks and materials that comply with sustainability standards.

·

·

Reducing waste by minimizing the need for separate labels.

·

·

Innovative designs that encourage recycling and responsible disposal.

·

Features of Cylindrical Printing Technology

1. Versatility

Cylindrical printing is compatible with various materials and can be applied to a wide range of beverage containers. From aluminum cans to glass bottles, this technology ensures that:

·

Brands can maintain design consistency across different products.

·

·

Lower costs associated with inventory due to the ability to print on-demand.

·

2. High-Quality Printing

Thanks to advancements in printing technology, cylindrical printing offers superior resolution and detail. Features include:

·

High-definition graphics that capture even the smallest details.

·

·

Durable finishes that withstand condensation, sunlight, and handling.

·

·

Reliable color accuracy that maintains brand integrity across batches.

·

3. Efficiency and Speed

Cylindrical printing machines are designed to increase production efficiency. Key aspects include:

·

Faster print speeds that enable quick turnaround times.

·

·

Simplified setup processes for different products and designs.

·

·

Integration with automated systems that reduce manual intervention.

·

Case Studies: Brands Leading the Way

Numerous brands have embraced cylindrical printing and witnessed positive results. Here are a few standout examples:

1. Coca-Cola

Coca-Cola utilized cylindrical printing on its iconic glass bottles to introduce limited-edition designs. This approach not only boosted customer engagement but also sparked conversations on social media, enhancing brand visibility.

2. BrewDog

BrewDog, a well-known craft beer producer, has used cylindrical printing to tell compelling stories about their brewing process and environmental commitments directly on their cans, drawing in environmentally conscious consumers.

3. PepsiCo

Pepsi has leveraged cylindrical printing to create visually striking campaigns that align with seasonal themes, helping to maintain consumer interest and boost sales during specific periods.

Challenges and Considerations

While cylindrical printing offers many advantages, it also presents unique challenges. Brands must consider:

·

Initial investment in specialized printing equipment, which can be significant.

·

·

Training staff to operate new machinery effectively.

·

·

Ongoing maintenance and calibration of printing equipment to ensure quality output.

·

By addressing these challenges, brands can fully harness the potential of cylindrical printing while reaping its many benefits.

Conclusion

Cylindrical printing is undeniably changing the landscape of beverage packaging design. Its ability to enhance visual appeal, improve brand recognition, and support sustainability efforts makes it an attractive choice for brands looking to differentiate themselves in a competitive market. As technology continues to advance, we can expect even more innovative applications and techniques in the future.

For beverage producers aiming to elevate their packaging design, explore our high-quality cylindrical printers here and find the perfect solution for your packaging needs.

FAQ

What is cylindrical printing?

Cylindrical printing is a method of printing that wraps graphics around the entire surface of cylindrical objects, such as bottles and cans. This technique allows for full customization of the packaging design.

What are the main benefits of cylindrical printing for beverage packaging?

The main benefits include enhanced visual appeal, improved brand recognition, and the opportunity for sustainable packaging solutions.

How does cylindrical printing differ from traditional flat printing?

Cylindrical printing utilizes the three-dimensional surface of a container, allowing for more extensive and vibrant designs, while traditional flat printing is limited to the two-dimensional surface of a label.

Is cylindrical printing cost-effective?

While the initial investment in cylindrical printing technology can be high, the potential for lower costs through reduced material waste and faster production times can lead to long-term savings.

Can all materials be used for cylindrical printing?

Yes, cylindrical printing can be used on various materials, including glass, plastic, and metal, making it versatile for different beverage packaging needs.