How to Add Raised Effects with Cylinder UV Embellishments

Introduction

In the world of print design, standing out can be a challenge. With competition growing in various industries, finding ways to enhance your product's appeal has never been more crucial. One innovative method to achieve this is through cylinder UV embellishments, which allow for the creation of eye-catching raised effects on various cylindrical materials. In this blog post, we'll explore what cylinder UV embellishments are, how they can benefit your branding, and how to effectively add these effects to your designs.

Understanding Cylinder UV Embellishments

Cylinder UV embellishments involve applying a layer of UV coating on various cylindrical objects, such as bottles, cans, and tubes. This process creates a tactile, raised effect that enhances the visual appeal of the product. These embellishments are not just for aesthetics; they serve functional purposes as well, such as adding durability and protection to printed surfaces.

The Process of Adding Raised Effects

The process of adding raised effects using cylinder UV embellishments generally includes the following steps:

·

Design Creation: Start with a digital design that incorporates the areas where you want the raised effects.

·

·

Selection of Materials: Choose the appropriate cylindrical materials that will be printed upon.

·

·

UV Coating Application: Use a cylindrical UV printer to apply the UV coating to the designated areas of your design.

·

·

Curing: After application, the UV coating is cured using UV light to solidify and create the raised effect.

·

·

Finishing Touches: Finally, inspect the printed product and make any necessary adjustments to ensure the quality meets your standards.

·

Benefits of Cylinder UV Embellishments

Using cylinder UV embellishments comes with a variety of benefits that can significantly elevate your branding strategies:

1. Enhanced Visual Appeal

The raised effects add dimension and texture to your products, making them more visually striking. This can lead to increased customer engagement and interest.

2. Differentiation in the Market

With so many products available, having unique embellishments can set your brand apart from competitors. Customers are more likely to choose a product that stands out visually.

3. Improved Durability

The UV coating acts as a protective layer, making the print more resistant to scratches, moisture, and fading, thereby improving the product's longevity.

4. Eco-Friendly Options

Many modern UV coatings are formulated to be environmentally friendly, allowing brands to maintain their commitment to sustainability while still achieving stunning results.

5. Versatile Applications

Cylinder UV embellishments can be applied to a myriad of products, including:

·

Cosmetic bottles

·

·

Food and beverage packaging

·

·

Pharmaceutical containers

·

·

Promotional items

·

Features of Cylinder UV Printing

When considering whether to implement cylinder UV embellishments in your production processes, it’s essential to understand the unique features this printing technique offers:

High-Quality Output

Cylinder UV printing ensures vibrant colors and sharp detail, bringing your designs to life with precision. The quality is often superior to traditional methods.

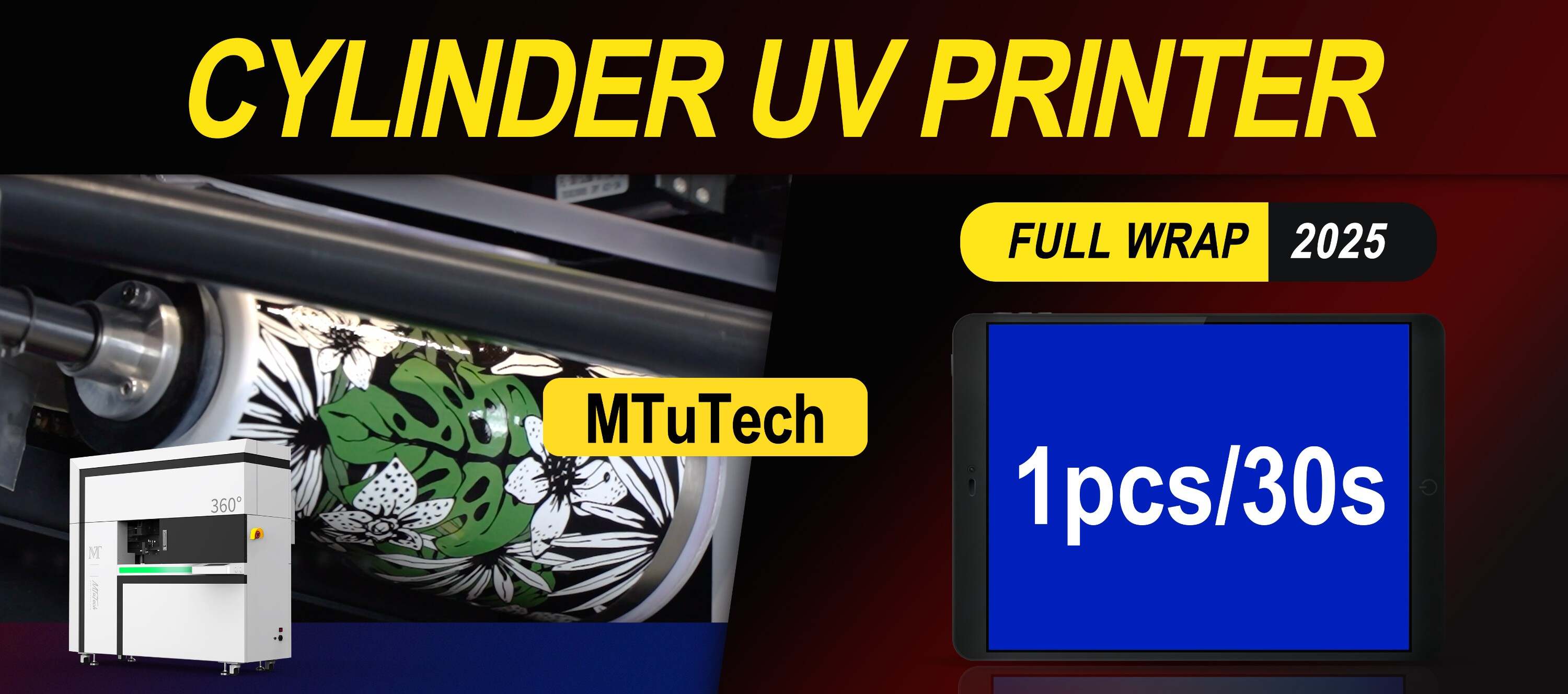

Quick Turnaround Time

Once cured, the products are ready for packaging, enabling quicker production cycles compared to conventional printing processes.

Customization Options

With cylinder UV printing, you can customize textures, colors, and designs to meet specific branding needs, allowing for creative flexibility.

Best Practices for Implementing Cylinder UV Embellishments

If you’re considering adding raised effects with cylinder UV embellishments, here are some best practices to ensure successful implementation:

1. Collaborate with Experts

Partnering with professionals who specialize in cylinder UV printing can help you navigate the technical aspects and achieve optimal results.

2. Invest in Quality Equipment

Utilizing high-quality cylindrical printers is essential for ensuring precision and durability. Explore our high-quality Cylindrical printers here to find equipment that meets your needs.

3. Test Prototypes

Before mass producing, create prototypes to test design elements and visibility to fine-tune your final product.

4. Regular Maintenance

Ensure your printing equipment is well-maintained to avoid disruptions and guarantees consistent quality across production runs.

Conclusion

Incorporating raised effects with cylinder UV embellishments can significantly enhance the aesthetic and functional value of your products. This innovative printing technique not only provides a stunning visual experience but also helps brands differentiate themselves in a crowded marketplace. By partnering with the right printing professionals and investing in quality equipment, you'll be well on your way to creating outstanding products that captivate your audience.

FAQ

What types of products can benefit from cylinder UV embellishments?

Several products can benefit, including cosmetic packaging, beverage bottles, food containers, and promotional items, among others.

Is cylinder UV printing environmentally friendly?

Many modern UV coatings are formulated to be eco-friendly, allowing brands to reduce their environmental impact while still achieving great results.

How do I ensure quality in cylinder UV printing?

Working with experienced professionals and investing in high-quality equipment can greatly enhance the quality of your cylinder UV printing.

Can I customize my designs when using UV embellishments?

Yes! Cylinder UV printing allows for a wide range of customization options, including textures, colors, and designs, tailored specifically to your brand needs.

What is the curing process for UV coatings?

The UV coating is cured using UV light immediately after application, solidifying the coating and providing the raised effect.