How to Add White and Varnish Layers in Cylindrical Printing

Introduction

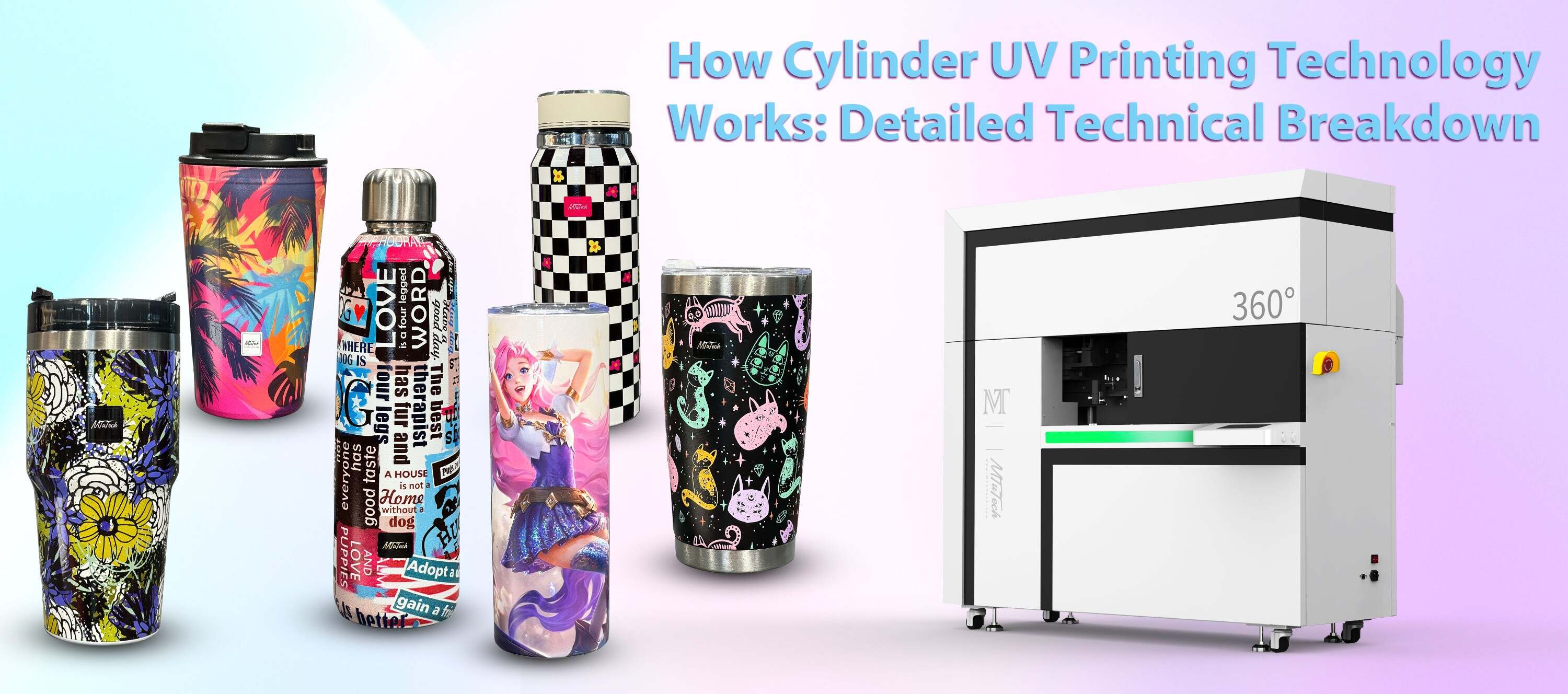

Cylindrical printing has revolutionized the way we approach printing on non-flat surfaces, such as bottles, jars, and other cylindrical objects. The ability to apply unique finishes like white and varnish layers not only enhances the aesthetic appeal but also adds functional properties to the printed item. This blog will explore how to effectively add white and varnish layers in cylindrical printing, highlighting the techniques, benefits, and tips for achieving professional results.

Understanding the Basics of Cylindrical Printing

Before delving into the specifics of adding layers, it's essential to understand the fundamentals of cylindrical printing. This printing technique involves wrapping a design around a 3D object, which poses unique challenges compared to flat surfaces. Specialized printers, often equipped with UV technology, are employed to achieve vibrant colors and finishes.

Key Components of Cylindrical Printing:

·

Cylindrical Printer: Typically, UV printers designed to adapt to the curvature of the object.

·

·

Ink Composition: Includes specific inks optimized for adhesion on curved surfaces.

·

·

Drying Mechanism: Important for immediate curing, preventing smudging and ensuring vibrant finishes.

·

The Importance of White Layers in Cylindrical Printing

White layers play a crucial role in cylindrical printing, especially when working with transparent or colored substrates. The application of a white layer acts as a foundation, enabling other colors to stand out vibrantly.

Why You Should Add a White Layer:

·

Enhanced Color Vibrancy: Without a white layer, colors may appear dull or muted when printed on transparent or dark surfaces.

·

·

Improved Contrast: A white base allows for better contrast, making the design more legible and visually appealing.

·

·

Functional Benefits: Provides a barrier that can protect the underlying substrate from UV light damage.

·

Applying White Layers in Cylindrical Printing

The process of applying a white layer in cylindrical printing involves several critical steps to ensure that the foundation is laid correctly before any additional colors are applied.

Step-by-Step Process for Applying White Layer:

1.

Prepare the Printer: Ensure your cylindrical printer is calibrated and ready for white ink application.

2.

3.

Select the Right Ink: Use high-opacity white ink designed for cylindrical printing. This ensures better coverage and adherence.

4.

5.

Adjust Settings: Make necessary adjustments to print speed, ink volume, and drying settings to optimize the application of the white layer.

6.

7.

Print the White Layer: Initiate the printing process to apply the white layer evenly around the cylindrical object.

8.

9.

Dry the Layer: Utilize UV curing after printing the white layer to ensure it adheres properly to the substrate.

10.

What is Varnish Layering?

A varnish layer serves as a protective coat that enhances the finish of printed items. It can add gloss or matte finishes, depending on the desired outcome. Varnish layers also protect printed designs from scuffs, scratches, and environmental factors.

Benefits of Adding Varnish Layers:

·

Surface Protection: Helps shield prints from wear and tear.

·

·

Visual Appeal: Adds a glossy or matte finish that improves the overall look.

·

·

Enhanced Texture: Can give a tactile feel that distinguishes the printed product.

·

How to Apply Varnish Layers in Cylindrical Printing

Applying a varnish layer is relatively straightforward and often follows the white layer application. It is vital to wait until the previous layers have fully cured before applying varnish.

Step-by-Step Process for Applying Varnish Layer:

1.

Finish Curing the White Layer: Ensure the white layer is completely dry and cured before proceeding.

2.

3.

Select Varnish Type: Choose between gloss and matte varnish according to your desired finish.

4.

5.

Printer Settings: Adjust printer settings for varnish application, such as ink volume and speed.

6.

7.

Print the Varnish Layer: Start the process of varnishing, ensuring an even application around the object.

8.

9.

Final Curing: Cure the varnish layer under UV light to harden and protect your print.

10.

Tips for Successful Layering

Here are some expert tips to enhance your cylindrical printing projects:

·

Test Before Production: Always conduct a test print on a sample substrate to fine-tune your settings.

·

·

Maintain Equipment: Regularly clean your printer and check for wear and tear on components to ensure consistent performance.

·

·

Manage Environment: Keep your printing environment controlled; temperature and humidity can affect ink performance and adhesion.

·

·

Consult Manufacturer Recommendations: Follow specific ink and printer guidelines to achieve the best results.

·

Conclusion

Adding white and varnish layers in cylindrical printing can significantly elevate the quality and appeal of your printed products. Understanding the correct techniques and processes is vital for achieving professional results. With careful attention to detail and the right equipment, you can create stunning printed items that will stand out in the market.

If you’re looking to explore your options for cylindrical printing, explore our high-quality Cylindrical printers here and see how they can meet your specific needs.

FAQ

What substrates can be used for cylindrical printing?

Cylindrical printing can be performed on a variety of substrates, including glass, plastic, metal, and ceramic surfaces. The choice of substrate often depends on the end-use of the printed item.

How do I ensure the white layer adheres properly?

To ensure proper adhesion of the white layer, make sure your printer settings are calibrated correctly and that the substrate is clean and free from dust or oils. Additionally, consider using high-opacity white ink specifically designed for your materials.

Can I use varnish on all types of inks?

Not all inks are compatible with varnish. Always consult with the ink manufacturer to confirm compatibility, especially if you are using special effects inks or coatings.

How do I choose between gloss and matte varnish?

Your choice between gloss and matte varnish should depend on the desired aesthetic. Gloss finishes can enhance color vibrancy and depth, while matte finishes can give a more sophisticated and subtle look.

What maintenance does a cylindrical printer require?

Regular maintenance includes cleaning print heads, ensuring proper ink flow, and checking for software updates. It's also essential to keep the printer in a controlled environment to prevent issues such as clogged nozzles.