How to Avoid Ink Pooling on Curved Cylindrical Surfaces

Introduction

In the world of printing, particularly when dealing with curved cylindrical surfaces, a common challenge arises: ink pooling. This phenomenon can significantly affect the quality of prints, leading to smudged lines, uneven color distribution, and overall dissatisfaction with the finished product. To achieve pristine results, it’s crucial to understand the mechanics behind ink application on these surfaces and implement appropriate strategies to mitigate ink pooling issues. In this article, we will explore practical methods to avoid ink pooling while printing on curved cylindrical objects, ensuring that your projects maintain the highest quality standards.

Understanding Ink Pooling

Ink pooling occurs when excess ink gathers at low points or edges of a surface rather than adhering evenly. This can be particularly problematic when printing on curved surfaces, such as bottles, jars, and other cylindrical objects, as gravity and surface tension play significant roles in how ink behaves.

The Causes of Ink Pooling

Several factors contribute to ink pooling on curved cylindrical surfaces:

·

Inadequate Surface Preparation: The surface of the material may not be properly prepared for printing, leading to poor ink adhesion.

·

·

Incorrect Printer Settings: Misconfigured printer settings can lead to an improper amount of ink being applied.

·

·

Ink Viscosity: Too thick or too thin ink can determine how well it spreads across a curved surface.

·

·

Cylindrical Surface Geometry: The curvature and diameter of the object can affect ink application, leading to uneven distribution.

·

Strategies to Prevent Ink Pooling

To achieve consistent and high-quality prints on curved cylindrical surfaces, consider the following strategies:

1. Proper Surface Preparation

Ensuring that the surface of the cylindrical object is prepared correctly is vital. Follow these steps:

·

Clean the Surface: Remove any dust, oil, or residues using appropriate cleaning agents.

·

·

Use Adhesion Promoters: Consider applying an adhesion promoter to enhance ink bonding to the substrate.

·

·

Test Surface Compatibility: Before a large batch, test different surfaces to identify the best preparation techniques.

·

2. Optimize Printer Settings

Fine-tuning your printer settings can significantly reduce the chances of ink pooling:

·

Adjust Ink Density: Decrease ink density to prevent excess ink from being applied.

·

·

Modify Print Speed: Slower print speeds allow for more uniform ink distribution, reducing the risk of pooling.

·

·

Utilize Print Head Calibration: Regular printer maintenance and calibration ensure consistent ink application.

·

3. Choose the Right Ink

The type of ink used can dramatically impact the printing process on curved surfaces:

·

Ink Viscosity: Select ink with the appropriate viscosity to enhance flow and reduce pooling.

·

·

Fast-Drying Inks: Consider using fast-drying inks to minimize the time ink has to pool before drying.

·

·

UV-Curable Inks: For certain projects, UV-curable inks can provide a quick, even cure and minimize pooling.

·

4. Implement Advanced Print Techniques

Utilizing advanced printing techniques can further mitigate the risk of ink pooling:

·

Multiple Pass Printing: This technique applies multiple thin coats of ink, allowing for better distribution and reduced pooling.

·

·

Variable Dot Printing: Adopting variable dot technologies enables better control over ink droplets, leading to more even application.

·

·

Heat and Pressure Applications: Certain printing methods utilize heat and pressure to ensure ink adheres evenly.

·

Best Practices for Successful Printing

In addition to strategies aimed at preventing ink pooling, implementing best practices can help enhance overall print quality:

·

Perform Regular Maintenance: Keep printers clean and well-maintained to prevent common printing issues.

·

·

Conduct Trial Runs: Always perform test prints on sample objects before beginning a full production run.

·

·

Document Findings: Maintain records of successful and unsuccessful print runs to identify patterns and solutions.

·

Evaluating the Impact of Ink Pooling

To evaluate the effectiveness of your strategies in reducing ink pooling, consider the following:

·

Visual Inspection: Regularly conduct inspections of printed items for signs of pooling or uneven coverage.

·

·

Customer Feedback: Gather client feedback regarding print quality to identify areas needing improvement.

·

·

Adjust Techniques Accordingly: Use data from trials and inspections to continuously refine your printing techniques.

·

Conclusion

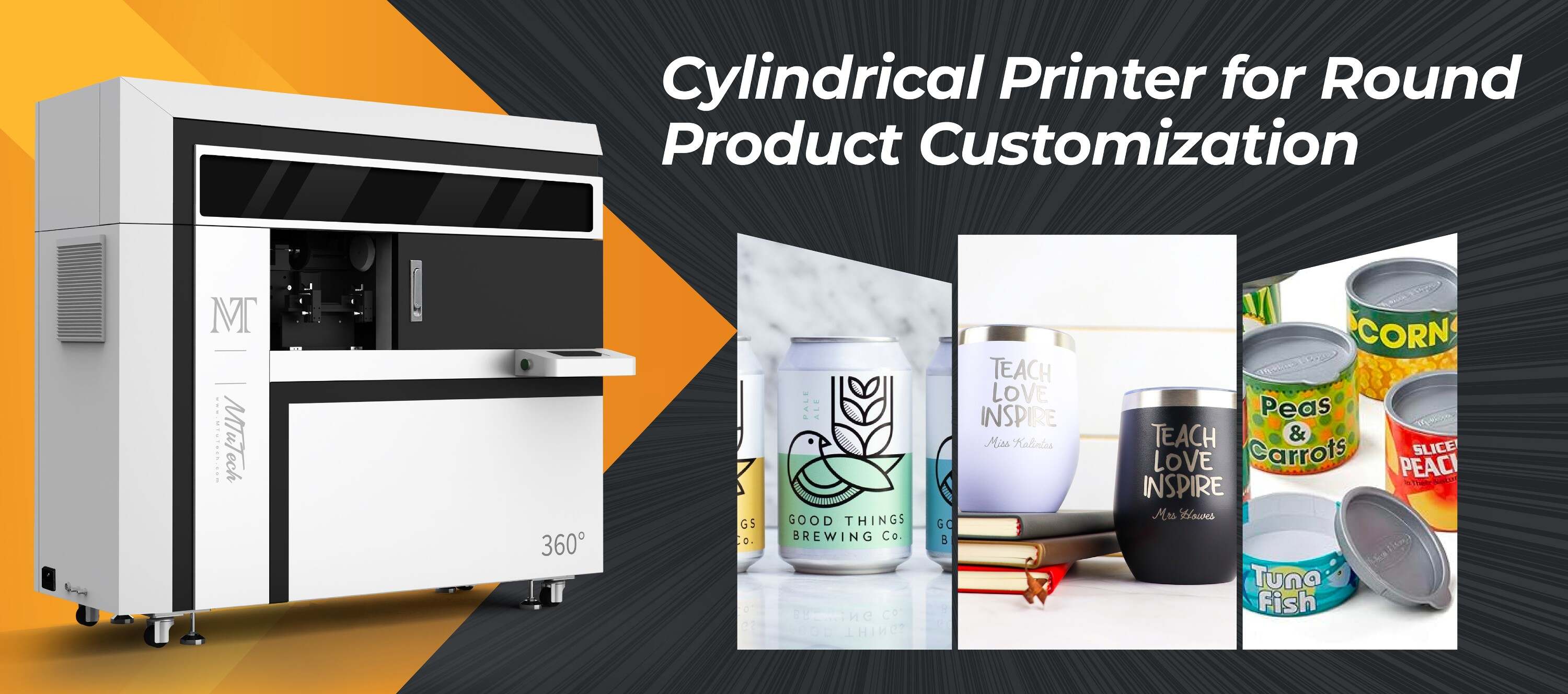

Avoiding ink pooling on curved cylindrical surfaces is an essential consideration for achieving high-quality prints. By understanding the causes of ink pooling and implementing effective strategies, including proper surface preparation, optimizing printer settings, selecting the right ink, and incorporating advanced techniques, you can ensure that your printing projects are successful and meet the standards of both you and your clients. For those serious about enhancing their printing capabilities, explore our high-quality Cylindrical printers here that are specifically designed to tackle these challenges with ease.

FAQ

What is ink pooling?

Ink pooling occurs when excess ink accumulates at low spots or edges on a surface, resulting in uneven print quality and unsatisfactory finishes.

What are the main causes of ink pooling?

Inadequate surface preparation, incorrect printer settings, ink viscosity, and the geometry of the cylindrical surface are the primary factors that contribute to ink pooling.

How can I improve surface preparation for printing?

Properly clean the surface, use adhesion promoters, and test surface compatibility to enhance ink bonding and adherence.

What types of ink are best for reducing ink pooling?

Choosing inks with appropriate viscosity, opting for fast-drying inks, and utilizing UV-curable inks can help mitigate pooling issues.

Is it necessary to perform trial runs before full production?

Yes, conducting trial runs on sample objects is crucial to ensure optimal print quality and adjust settings as needed for the full production run.

How often should I maintain my printer?

Regular maintenance should be performed according to the manufacturer’s recommendations, and special attention should be given when changing ink types or experiencing print quality issues.