How to Integrate Cylinder UV Printing into Your Existing Production Line

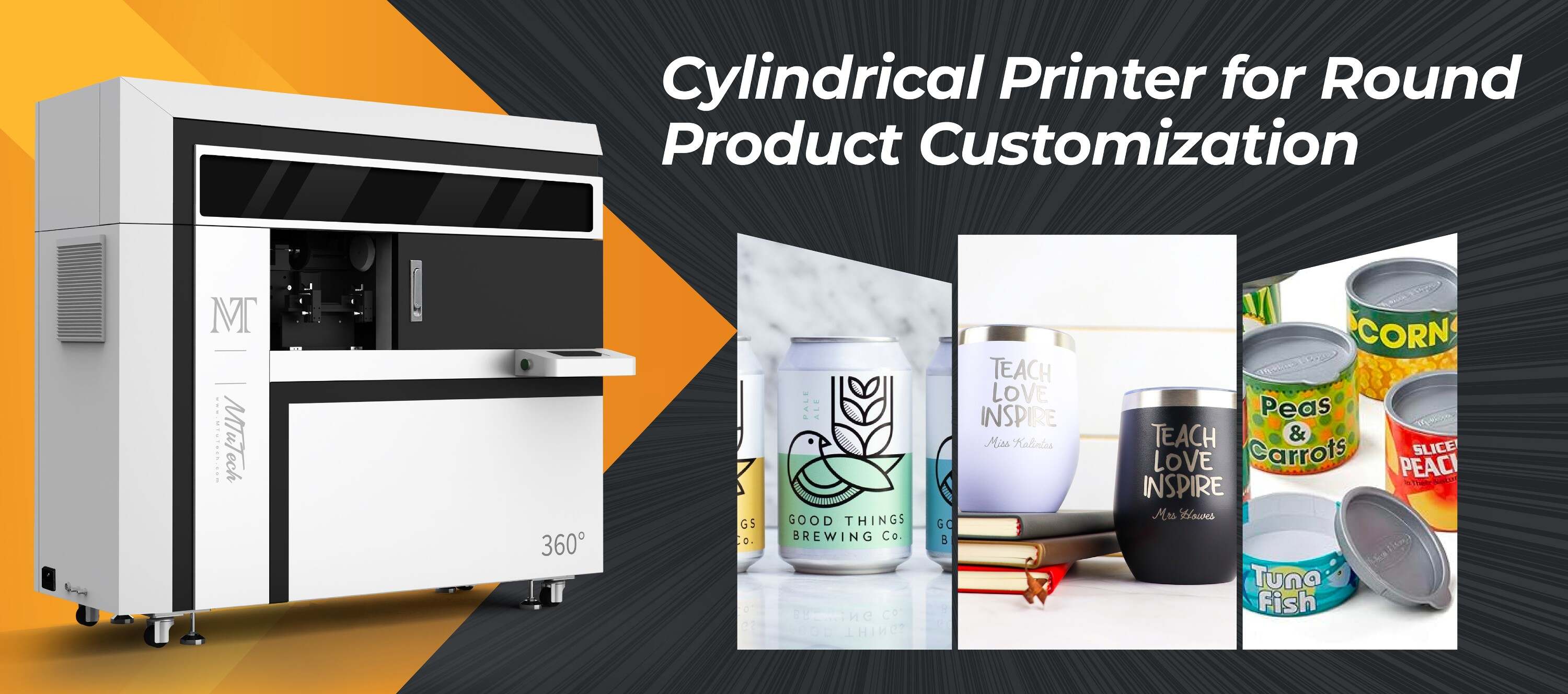

Integrating cylinder UV printing into an existing production line is an excellent way for businesses to expand their capabilities and enhance their offerings. Whether you're in the packaging, promotional products, or industrial equipment sectors, UV printing can be a game-changer by enabling you to print on cylindrical surfaces like bottles, cans, and tubes. However, the process of integrating a UV printer into an existing system may seem daunting at first, especially if you have a production line that relies on different printing technologies.

In this blog, we’ll explore how you can successfully integrate cylinder UV printing into your production line, streamline your processes, and maximize your return on investment.

1. Understand the Benefits of Cylinder UV Printing

Before jumping into the integration process, it’s crucial to understand why cylinder UV printing is beneficial for your production line:

- High-quality, durable prints: UV inks offer superior adhesion, ensuring vibrant colors that are long-lasting, even when exposed to harsh conditions.

- Customization: UV printing allows for printing on a wide variety of materials, including plastics, metals, and ceramics. This versatility makes it ideal for businesses that need to customize products like bottles, packaging, or promotional items.

- Fast curing: The UV curing process is immediate, meaning there’s no waiting for the ink to dry, which increases production speed.

- Environmental benefits: UV inks are eco-friendly because they don’t emit harmful volatile organic compounds (VOCs), which reduces the environmental impact of your production process.

Knowing the advantages can help you assess how it aligns with your current production goals and business strategy.

2. Evaluate Your Current Production Line Setup

The first step in integrating cylinder UV printing is to evaluate your existing production line setup. You’ll need to assess the following aspects:

- Space and layout: UV printers require enough space to operate efficiently. Measure the available space on your production floor to determine where the printer will fit and how it will interact with other equipment.

- Workflow and automation: Consider how the new UV printer will integrate with your existing machinery, such as conveyors, material handlers, and packaging systems. If your current workflow is manual, you may need to invest in automation to streamline the process.

- Quality control: Implementing UV printing requires some adjustments to your quality control processes. You will need to test the durability, color accuracy, and overall quality of the prints to ensure they meet your standards.

3. Choose the Right Cylinder UV Printer for Your Needs

Selecting the right UV printer is critical to ensuring that the integration process goes smoothly. Here are some factors to consider:

- Size and print area: Choose a cylinder UV printer that can accommodate the size of the cylindrical products you plan to print on. Some printers have a larger print area, while others are designed for smaller objects.

- Material compatibility: Make sure the printer is compatible with the materials you plan to use. Most UV printers can handle a wide variety of materials, but it’s essential to check that the machine suits your production needs.

- Printer speed: The speed of the printer will affect your overall production rate. Choose a printer that can keep up with your manufacturing volume, ensuring that the integration doesn’t slow down your workflow.

- Ease of use: The printer should be easy to operate and maintain. Look for features like user-friendly software and built-in diagnostics that help streamline the printing process.

4. Plan for the Integration Process

Once you’ve selected the right UV printer, the next step is planning for its integration. Here’s what you should focus on:

- Training your team: Your employees will need proper training to operate the new printer efficiently. Provide hands-on training and detailed manuals to help them become familiar with the UV printing process.

- Software and system integration: Cylinder UV printers often come with specialized software for designing, printing, and controlling the printing process. Ensure that the software integrates with your existing systems, such as inventory management or design software, to reduce the chances of errors and inefficiencies.

- Adjusting the workflow: Depending on the complexity of your existing production line, you may need to adjust the workflow to incorporate the UV printer. For example, you might need to add new stations for product loading/unloading, quality checks, or packaging.

- Test runs: Before launching full-scale production, conduct test runs to ensure everything is working smoothly. Make any necessary adjustments to the machine settings, workflow, and software to optimize performance.

5. Optimize Maintenance and Troubleshooting

One of the key factors in keeping your cylinder UV printer integrated into your production line is regular maintenance and troubleshooting:

- Routine maintenance: UV printers require periodic maintenance to keep them running at optimal levels. Ensure that your team is trained on how to clean and maintain the printer regularly. This includes checking ink levels, cleaning print heads, and inspecting the UV light source.

- Troubleshooting common issues: Be prepared for occasional issues that may arise, such as clogged nozzles, inconsistent print quality, or software malfunctions. Familiarize yourself with common problems and solutions, or ensure that you have access to technical support when needed.

6. Measure ROI and Efficiency Gains

Once your UV printer is fully integrated into your production line, it’s essential to measure the return on investment (ROI) and efficiency gains. Track metrics such as:

- Production speed: Monitor how quickly the UV printer can print on cylindrical products compared to previous methods.

- Print quality and consistency: Evaluate how well the printer performs in terms of color accuracy and print durability.

- Cost savings: Analyze how the printer’s fast curing and reduced ink usage contribute to cost savings over time.

These metrics will help you assess whether the integration has met your expectations and whether any adjustments need to be made.

Conclusion

Integrating cylinder UV printing into your existing production line can provide a substantial boost to your business, allowing you to offer customized, high-quality printed products at a faster rate. With careful planning, the right equipment, and proper training, this technology can become a seamless part of your production process. It offers significant advantages, including increased productivity, enhanced customization, and eco-friendly practices, making it a great investment for businesses looking to stay ahead of the competition.

For a detailed guide on how cylinder UV printing is transforming custom printing solutions, check out [this link](https://www.mtutech.com/Blogfor360RotaryUVPrinter/Cylinder-UV-Printer-Transforming-Custom-Printing-Solutions-759.html).