How to Print Detailed Artwork on Small Cylindrical Products

Introduction

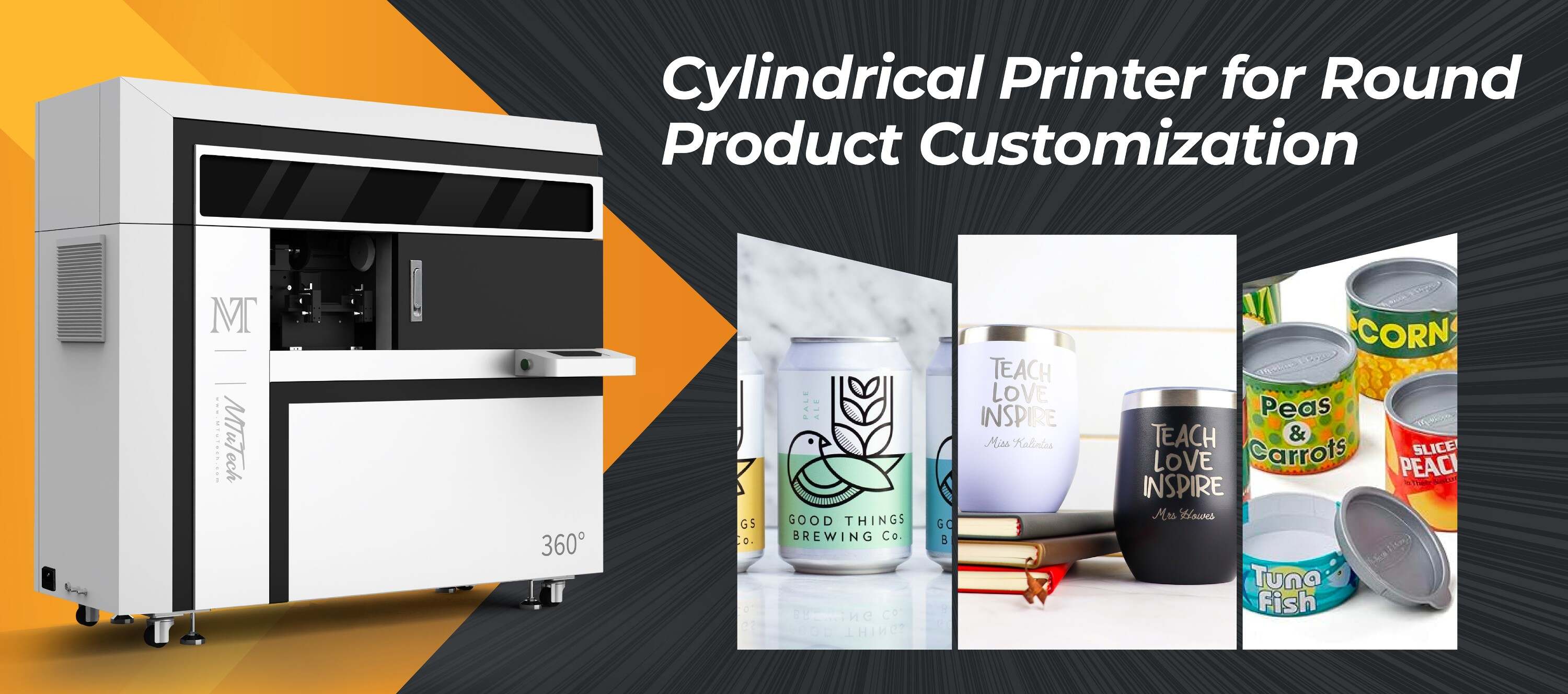

In the world of product branding and customization, printing intricate artwork on small cylindrical items has become a popular trend. Whether it’s for promotional giveaways, personal gifts, or unique merchandise, the ability to effectively print on cylindrical surfaces can elevate a product’s appeal and stand out in a crowded market. This blog post will explore the various methods and technologies available for printing detailed artwork on small cylindrical products, including how to choose the right printer, materials, and techniques to achieve stunning results.

Understanding the Importance of Cylindrical Printing

Cylindrical printing is essential in many industries, including beverage, cosmetics, and promotional products. The appeal of custom designs on drinkware, containers, or any round items can enhance brand visibility and customer loyalty.

Benefits of Printing on Cylindrical Products

·

Enhanced Branding: Unique and eye-catching designs can help businesses create a lasting impression.

·

·

Versatility: Small cylindrical products come in various sizes and materials, making them suitable for multiple applications.

·

·

Durability: Depending on the printing technique, your prints can be highly resistant to wear and tear.

·

·

Customization: Personalize items easily for gifts or promotional campaigns, adding value to your offerings.

·

Choosing the Right Printing Method

When it comes to printing on cylindrical products, the method chosen can significantly impact the quality and durability of the print. Here are some popular techniques:

1. UV Printing

UV printing has become increasingly popular for small cylindrical items. This method uses ultraviolet light to cure the ink as it is printed.

·

Pros: Fast drying, high-resolution prints, can print on various materials (glass, plastic, metal).

·

·

Cons: Initial investment costs can be high; requires specialized equipment.

·

2. Screen Printing

Screen printing is a traditional method that involves pushing ink through a mesh screen. It’s effective for simple designs and large quantities.

·

Pros: Cost-effective for bulk orders, vibrant colors.

·

·

Cons: Less detail can be achieved with intricate designs compared to other methods.

·

3. Digital Printing

Digital printing directly applies the artwork to the surface of the item. It’s an excellent option for short runs and intricate designs.

·

Pros: High-quality images, no setup fees for small orders.

·

·

Cons: Limited durability unless coated, typically more expensive on a per-item basis than screen printing.

·

Factors to Consider When Printing on Cylindrical Products

To achieve the best results, consider the following factors:

1. Material of the Product

The type of material you’ll be printing on plays a significant role in determining the printing method. Here are common materials and corresponding considerations:

·

Glass: Works well with UV printing; needs careful handling to prevent breakage.

·

·

Metal: Durable, ideal for UV and digital printing; ensure the inks are compatible.

·

·

Plastic: Flexible, but can warp under heat; digital printing is often preferred.

·

2. Size and Shape

The dimensions of the cylindrical product can affect how the printing process is conducted. Smaller items may require specialized clamping systems for stability during printing.

3. Design Complexity

The intricacy of your artwork will dictate the most suitable printing technique. For detailed images and gradients, UV or digital printing are the best choices. Screen printing is more suitable for solid colors and simpler designs.

4. Volume

Your printing volume will influence costs and lead times. Digital printing can be more cost-effective for low-volume orders, while screen printing is ideal for larger runs.

Steps to Print Detailed Artwork

Once you’ve determined the right method for printing on small cylindrical products, follow these steps for a successful print:

1. Design Creation

Create your artwork using graphic design software. Ensure the resolution is at least 300 dpi for the best quality in printing. Save your file in the appropriate format (often PDF, TIFF, or PNG depending on the printer).

2. Prepare the Printer

Set up the printer according to the manufacturer's instructions, ensuring it is calibrated for cylindrical objects. Select the correct settings for speed, ink type, and curing method.

3. Test Print

Before running a full batch, conduct a test print to check for color accuracy and alignment. This step is crucial to avoid costly mistakes later.

4. Production Run

Once satisfied with the test print, begin your production run. Monitor the process to ensure quality control and address any issues promptly.

Post-Printing Considerations

After printing, handle the items with care to avoid smudging or scratching the designs. Depending on the ink used, you may want to apply a protective coating for increased durability. Additionally, cure UV prints properly to ensure maximum longevity.

Conclusion

Printing detailed artwork on small cylindrical products opens up a world of possibilities for branding, personalization, and creativity. By understanding the various printing methods and considerations involved, you can achieve stunning results that captivate your audience. Whether you’re exploring options for promotional materials or personal gifts, investing in the right technology and techniques can make all the difference. Explore our high-quality Cylindrical printers here and elevate your printing capabilities today!

FAQ

What types of cylindrical products can be printed on?

You can print on a wide variety of cylindrical products, including drinkware (such as tumblers and mugs), cosmetic containers, bottles, and promotional items like pens and keychains.

Is it possible to print full-color designs?

Yes, many modern printing methods like UV printing and digital printing allow for full-color prints, enabling intricate and vibrant designs on cylindrical products.

How durable are the prints on cylindrical items?

The durability of prints depends on the ink and curing method used. UV-printed and coated items tend to have higher durability and resistance to scratches, fading, and wear.

Can I print a design that wraps around the entire product?

Yes, it is possible to create designs that wrap around the entire cylindrical surface. Ensure that your artwork is designed with the product’s dimensions in mind for a seamless look.

What is the cost difference between different printing methods?

Screen printing is often more economical for large runs, while digital and UV printing may have higher upfront costs but are more suitable for smaller orders or more complex designs. Prices vary based on setup, materials, and quantities.