How to Print Multi-Layer Designs on Tumblers with UV Printers

Introduction

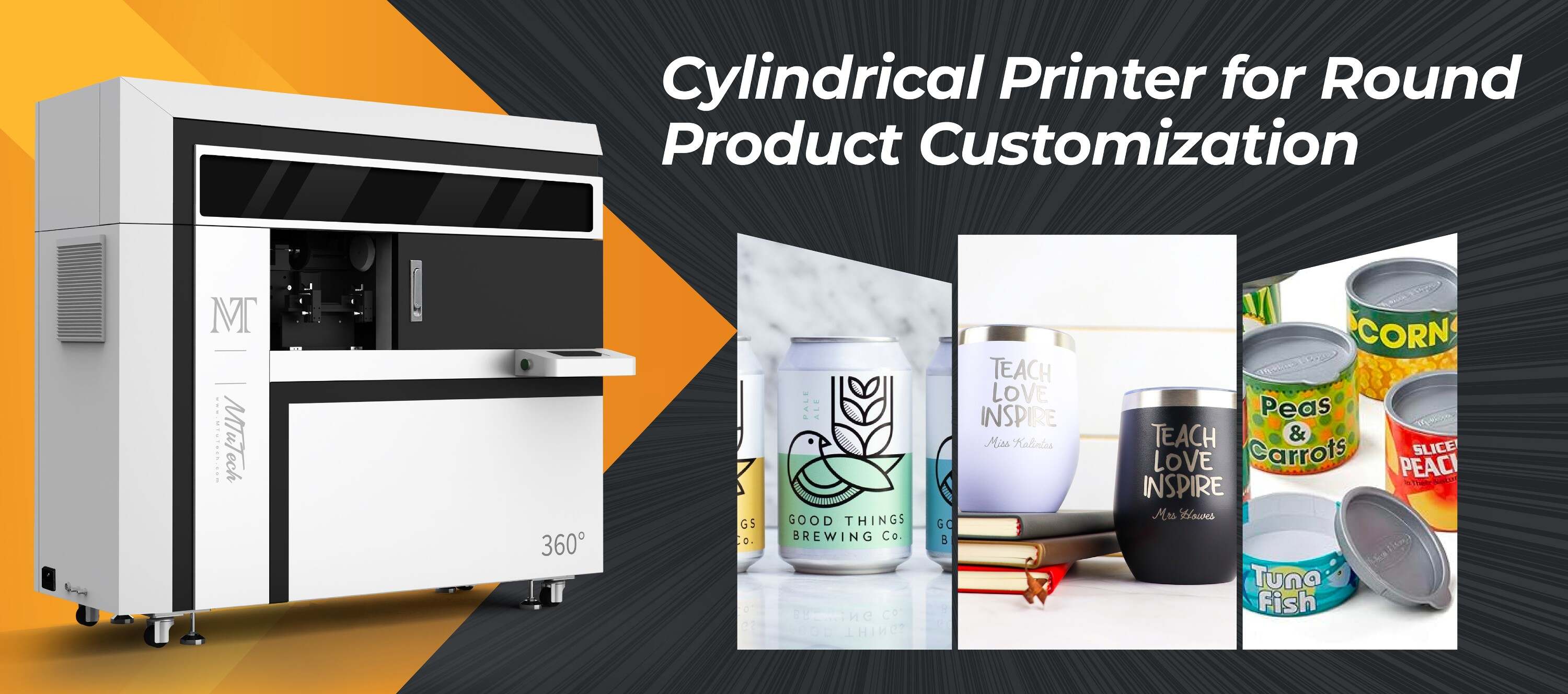

Printing multi-layer designs on tumblers has become a popular trend for businesses and individuals looking to create custom drinkware. UV printers offer a versatile and efficient solution for achieving high-quality, durable prints. In this blog post, we'll explore the entire process of printing on tumblers using UV printers, from understanding the technology to perfecting your multi-layer designs.

What is UV Printing?

UV printing is a digital printing technology that uses ultraviolet light to cure or dry ink as it is printed. The ink is exposed to UV light, which triggers a photochemical reaction that instantly solidifies it. This method offers several advantages over traditional printing methods, making it ideal for creating detailed and vibrant designs on a variety of materials, including tumblers.

Benefits of Using UV Printers for Tumblers

When it comes to printing on tumblers, UV printers stand out for numerous reasons. Here are some of the key benefits:

·

Durability: UV prints are resistant to scratching, fading, and chipping, ensuring that designs remain vibrant and intact over time.

·

·

Versatility: UV printers can print on a wide range of materials, including glass, metal, and plastic, making them perfect for various tumbler types.

·

·

Precision: High-resolution printing allows for intricate designs and multi-layer effects that are difficult to achieve with other methods.

·

·

Eco-friendly: UV inks contain fewer volatile organic compounds (VOCs) compared to traditional inks, resulting in a safer work environment.

·

·

Quick Turnaround: The UV curing process is immediate, allowing for faster production times without compromising quality.

·

Preparing Your Tumblers for Printing

Before you start printing your multi-layer designs on tumblers, there are several preparation steps to follow:

1. Choose the Right Tumblers

Select tumblers made from UV-compatible materials such as stainless steel, glass, or high-grade plastics. Ensure they have a smooth surface for optimal adhesion and print quality.

2. Clean the Surface

It's essential to clean the tumbler surface thoroughly. Use a lint-free cloth and a suitable cleaning agent to remove any dirt, grease, or residues that might affect the print quality.

3. Design Your Artwork

Creating a multi-layer design requires careful planning. Consider the following tips:

·

Layer Separation: Divide your artwork into distinct layers (e.g., background, graphics, and text) to enhance depth and dimension.

·

·

Color Matching: Ensure that colors will blend well when layered, keeping in mind how different hues interact.

·

·

File Format: Use vector graphics for sharp lines and scalability. Common formats include SVG, AI, or PSD.

·

Setting Up Your UV Printer

Now that your tumblers and designs are ready, it's time to set up your UV printer:

1. Configure the Printer Settings

Input the necessary settings into your UV printer software:

·

Material Type: Specify the type of tumbler you are printing on to ensure the right ink density and curing settings.

·

·

Layering Options: If your printer supports multi-layer printing, enable this feature to create depth in your designs.

·

·

Speed and DPI: Choose the appropriate printing speed and dots per inch (DPI) for your desired print quality.

·

2. Load the Tumblers

Securely load your tumblers into the printer. Make sure they are in the correct position to avoid any misalignment during printing.

Printing Multi-Layer Designs

Once your printer is set up, you can proceed to print your design. Follow these steps for best results:

1. Print the Base Layer

Start by printing the base layer of your design onto the tumbler. This layer usually consists of solid colors or backgrounds. Ensure proper curing to provide a solid foundation for subsequent layers.

2. Layer Additional Designs

After the base layer is fully cured, continue adding layers of graphics, text, or even textures. Monitor the curing process closely after each layer to maintain the integrity of your design.

3. Final Touches

After printing all layers, inspect the tumbler for any imperfections. If needed, you can add a clear UV coating for extra protection and shine.

Post-Printing Process

Once the printing process is complete, the tumblers may still require some post-processing:

1. Curing and Drying

Before handling your tumblers, allow them to cure fully, ensuring that the UV ink is completely set. This may vary based on the printer model and the ink used.

2. Quality Control

Conduct a quality check on each tumbler. Look for consistency in color, clarity, and overall finish. Any defects should be addressed, which may include cleaning or reprinting specific layers.

3. Packaging and Shipping

Once your tumblers pass the quality check, package them securely for shipping. Consider using protective materials to avoid damage during transit.

Conclusion

Printing multi-layer designs on tumblers with UV printers is an accessible and creative way to customize drinkware. Following best practices in preparation, setup, and printing will help you achieve stunning results. Whether you are a business looking to offer personalized tumblers or a DIY enthusiast, mastering UV printing can unlock a world of possibilities.

For those interested in diving deeper into UV printing technology, explore our high-quality Tumbler printers here to elevate your custom printing endeavors.

FAQ

Can I print on all types of tumblers?

Not all tumblers are suitable for UV printing. It’s best to use UV-compatible materials such as stainless steel, glass, or specific plastics designed for printing.

How long does the printing process take?

The printing time can vary based on the design complexity and the number of layers. Generally, the UV curing process is instant, allowing for quicker turnaround than traditional methods.

Do I need special software for UV printing?

Yes, specialized software is typically required for UV printers to manage printing settings, file formats, and design layers. Ensure you are using the right software for your printer model.

How durable are UV prints on tumblers?

UV prints are highly durable and resistant to fading, scratches, and chipping, making them ideal for everyday use.

Can I create my designs from scratch?

Absolutely! Many UV printers allow you to create and customize your designs using graphic design software. Just ensure your files are in a compatible format before printing.