How to Print on Cylindrical Objects with Handles or Indents

Introduction

The ability to print on cylindrical objects offers a fantastic range of possibilities for businesses and creative projects alike. From promotional items like mugs and water bottles to industrial applications such as parts and containers, the demand for high-quality printing on curved surfaces has grown significantly. However, printing on objects that feature handles or indents can be particularly challenging. This guide aims to equip you with the essential techniques and considerations necessary for successful printing on these unique shapes.

Understanding the Challenges

Before diving into methods and techniques, it's crucial to understand the inherent challenges when printing on cylindrical objects with handles or indents. Below are some key factors to consider:

·

Surface Alignment: Properly aligning the print head to ensure consistent quality across the entire surface can be tough, especially when dealing with curves and angles.

·

·

Ink Adhesion: Different materials have varying adhesion properties. Some surfaces may require pre-treatment to ensure the ink adheres properly.

·

·

Handle Positioning: Printing around or on handles requires clever techniques to avoid smudging or misalignment.

·

·

Indentations and Textures: Indents can affect how the surface is printed, necessitating adjustments in pressure and ink flow.

·

Choosing the Right Printer

The first step in successfully printing on cylindrical objects is selecting an appropriate printing technology. Here are some common options:

·

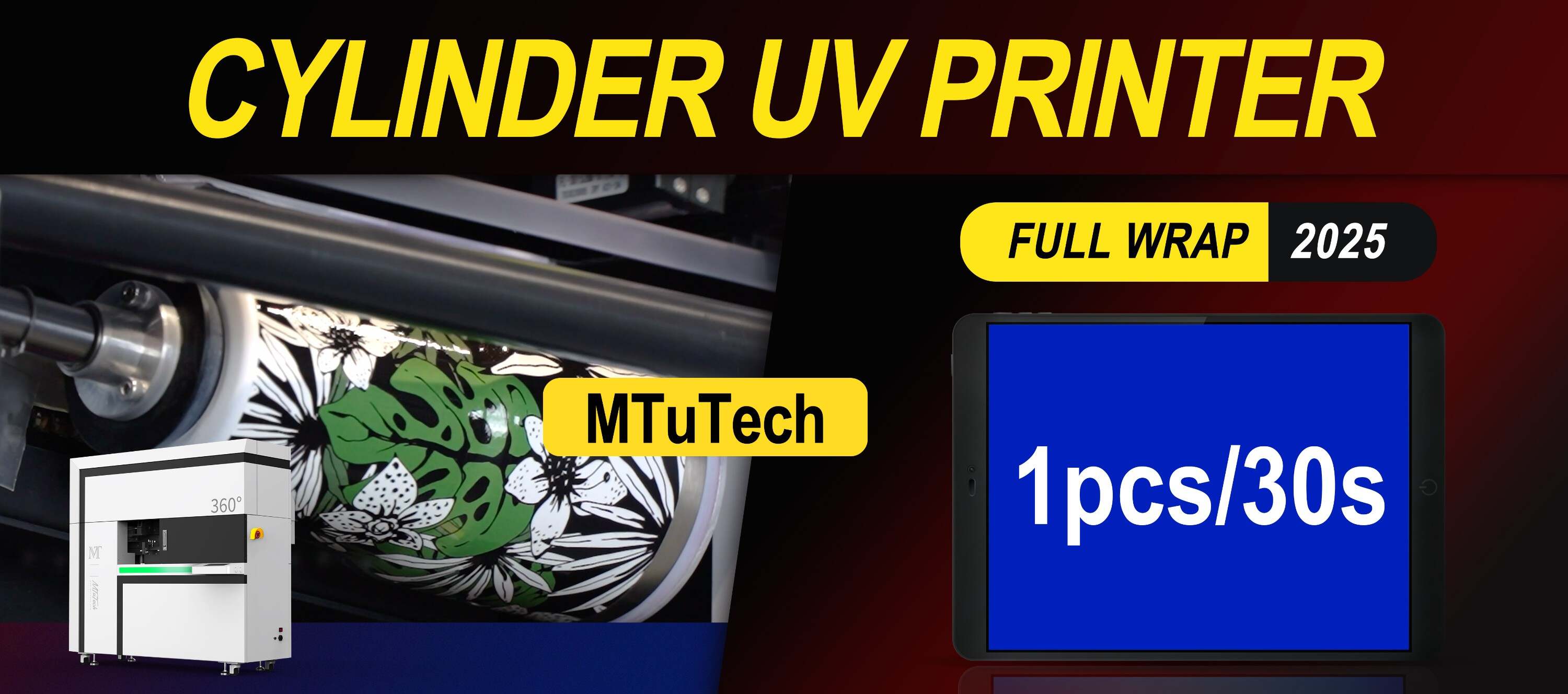

UV Printers: These printers use ultraviolet light to cure the ink as it is printed, making them ideal for printing on a wide range of materials, including plastics and metals. Their versatility and speed can cater well to cylindrical objects.

·

·

Pad Printing: A flexible method where the ink is transferred from a silicone pad to the product's surface. This technique can navigate complex shapes and indents with ease.

·

·

Screen Printing: Suitable for larger runs, screen printing offers excellent durability and vibrancy but may struggle with intricate details, especially around handles.

·

Preparing Your Object for Printing

Proper preparation is essential for achieving high-quality prints. Here’s how to prepare cylindrical objects:

·

Cleaning: Ensure the object is clean and free from dust, oils, or residues that could affect print quality.

·

·

Surface Treatment: Consider applying a primer or using a chemical treatment to enhance ink adhesion.

·

·

Positioning: Secure the cylindrical object in a way that minimizes movement during the printing process.

·

Techniques for Printing on Cylindrical Objects with Handles or Indents

Once you have your printer and object prepared, it’s time to delve into specific techniques for effective printing. Below are key methods to consider:

1. Digital Printing Techniques

When using digital printers, consider the following:

·

Wrap-Around Prints: Design your artwork in a way that wraps around the object seamlessly, accounting for the handle's position.

·

·

Use of Fixtures: Use fixtures or jigs that hold the object in place, ensuring the printer head is aligned properly.

·

2. Pad Printing Considerations

Pad printing is beneficial for objects with handles or indents due to its flexibility:

·

Custom Pads: Consider creating custom pads that conform to the shape of the handle or indent for more uniform coverage.

·

·

Multiple Hits: Sometimes, several passes of the pad may be necessary to achieve the desired opacity and quality.

·

3. Screen Printing Tips

For screen printing, these tips may help:

·

Breathe Through Designs: Avoid dense designs that can obscure finer details, especially around handles and indents.

·

·

Registration Marks: Utilize registration marks to align your prints accurately, especially important for multilayer prints.

·

Post-Printing Considerations

After printing, some post-printing considerations can enhance durability and appearance:

·

Curing: UV cures should be monitored closely to ensure even exposure and curing of the ink.

·

·

Quality Control: Inspect the prints for consistency in color, alignment, and texture.

·

·

Finishing Touches: A gloss or matte coating can protect the print and enhance its look.

·

Conclusion

Printing on cylindrical objects with handles or indents can present unique challenges; however, with the right tools, techniques, and attention to detail, high-quality results can be achieved. Whether you choose digital, pad, or screen printing, understanding the nuances of your equipment and applying the various methods discussed in this guide will empower you to create stunning printed products. To elevate your custom printing projects, consider exploring advanced printing technology such as high-quality cylindrical printers that suit your needs.

FAQ

What types of materials can be printed on cylindrical objects?

Most cylindrical printers can handle a variety of materials, including plastic, metal, glass, and ceramic. Understanding the specific requirements of your material will help ensure proper adhesion and print quality.

How can I ensure proper alignment for printing?

Using fixtures or jigs can significantly enhance alignment and consistency when printing. It’s also crucial to align the print head during setup for the best results.

Is it necessary to pre-treat surfaces before printing?

Pre-treating can enhance ink adhesion on certain materials, improving the quality and durability of your print. It’s advisable to research material-specific treatments.

How can I choose the right printer for my cylindrical printing needs?

Consider the volume of production, the types of materials you wish to print on, and the level of detail required for your designs. Evaluating your specific needs will help you select a printer that fits your requirements.