How to Reduce Waste in Cylindrical Print Production

Introduction

In today's environmentally conscious world, businesses across industries are seeking ways to minimize their impact on the planet. Cylindrical print production, often used for bottles, cans, and other cylindrical objects, is no exception. Waste reduction is not only beneficial for the environment but can also lead to significant cost savings and enhanced operational efficiency. This blog post will explore practical strategies to reduce waste in cylindrical print production.

Understanding Waste in Cylindrical Print Production

Waste in cylindrical print production can occur at various stages, including materials, energy usage, and process inefficiencies. Key areas where waste tends to accumulate include:

·

Excess ink and material usage

·

·

Post-production errors leading to scrapped products

·

·

Energy consumption during production processes

·

·

Poor inventory management resulting in unsold stock

·

Identifying and understanding these waste streams is the first step towards implementing effective reduction strategies.

Benefits of Reducing Waste

Implementing waste reduction strategies in cylindrical print production not only fosters sustainability, but it also provides several key advantages:

·

Cost Savings: Reducing material usage directly lowers production costs.

·

·

Improved Efficiency: Streamlined processes reduce the likelihood of delays and increase output.

·

·

Enhanced Brand Image: Companies prioritizing sustainability often benefit from improved public perception.

·

·

Regulatory Compliance: Reduced waste aligns with regulations aiming at sustainability practices.

·

Strategies to Reduce Waste

1. Optimize Material Usage

One of the most effective ways to reduce waste in cylindrical print production is to optimize material use. This can be achieved by:

·

Precise Measurements: Ensuring accurate measurements for materials used during the print process limits excess usage.

·

·

Digital Prototyping: Utilize digital previews to avoid the need for multiple physical prototypes during the design phase.

·

·

Material Recycling: Incorporate recycled materials wherever possible, minimizing the need for virgin resources.

·

2. Streamline Processes

Enhancing operational efficiency can also lead to significant waste reduction. Consider the following approaches:

·

Standardize Processes: Establishing standardized processes ensures consistency and reduces errors in production.

·

·

Continuous Training: Regularly train staff on best practices and new technologies to keep efficiency at its peak.

·

·

Implement Lean Manufacturing: Adopt lean principles to minimize waste in production processes by focusing on value-added activities.

·

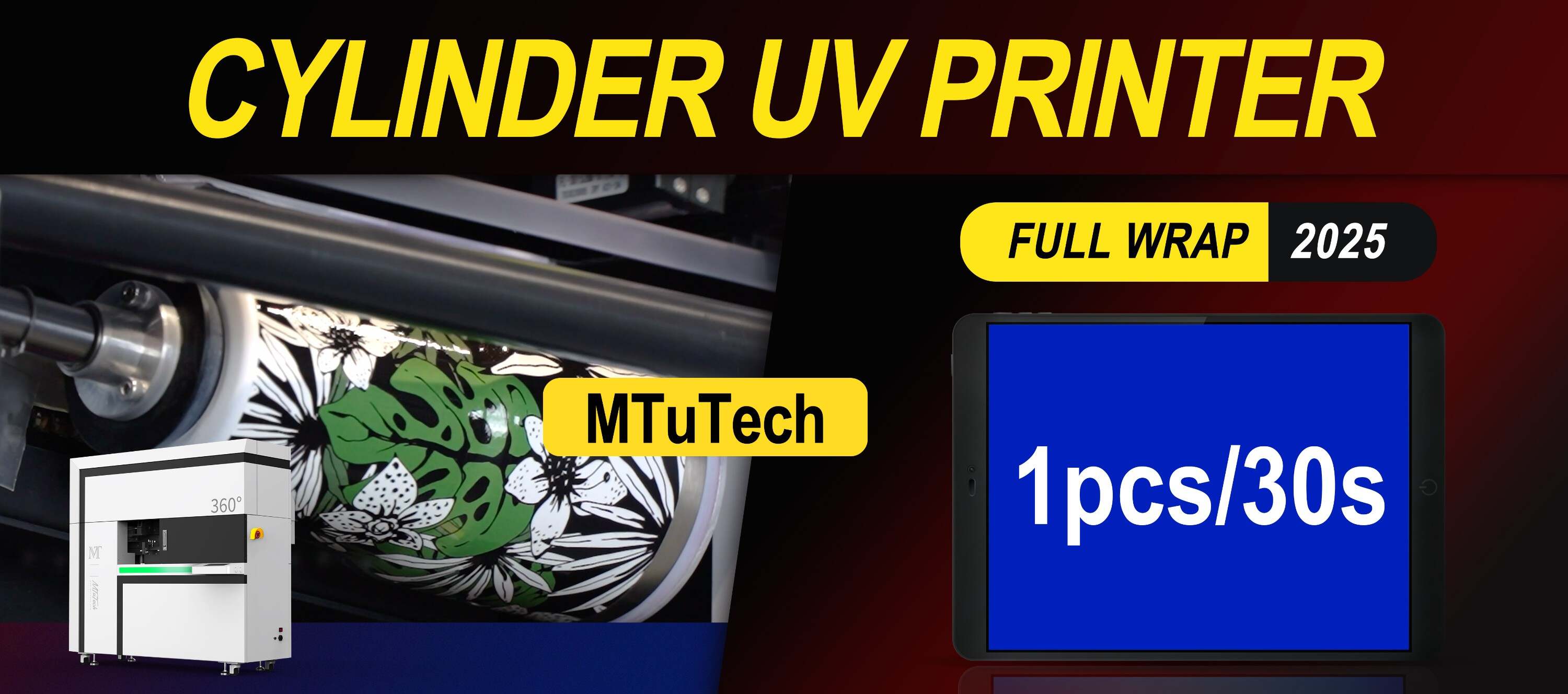

3. Invest in Advanced Technology

Advanced printing technologies can greatly reduce waste during production. Here are some technological solutions:

·

Cylindrical UV Printers: These printers utilize UV inks which cure instantly, reducing the amount of ink wasted.

·

·

Automation: Employ automated systems to monitor production processes, thereby identifying inefficiencies actively.

·

·

Real-time Monitoring: Using software to track production metrics helps in identifying and addressing waste in real-time.

·

4. Effective Inventory Management

Good inventory management is critical in preventing waste. Implement these practices:

·

Just-in-Time Inventory: This system ensures materials arrive only as they are needed, reducing excess stock.

·

·

Inventory Audits: Regularly audit inventory to identify slow-moving items that may cause waste if not managed effectively.

·

·

Demand Forecasting: Use data analytics to predict demand accurately, resulting in better planning of material needs.

·

5. Collaborate with Suppliers

Collaboration with suppliers can also lead to waste reduction. Strategies include:

·

Partnering for Sustainability: Work with suppliers who share your sustainability goals and practices.

·

·

Shared Waste Management Initiatives: Implement joint initiatives for recycling and reducing waste packaging.

·

·

Feedback Loop: Establish a feedback loop to share insights on material efficiency and improve processes continuously.

·

6. Engage Employees

Employee engagement is essential for any waste reduction strategy. Consider the following:

·

Awareness Programs: Organize programs to inform employees about the importance of waste reduction.

·

·

Incentives: Create incentive programs to encourage employees to come up with innovative waste reduction ideas.

·

·

Open Communication Channels: Foster an environment where employees feel comfortable sharing suggestions for improvement.

·

Conclusion

Reducing waste in cylindrical print production is not only a responsible choice but also a smart business strategy. By optimizing material usage, streamlining processes, investing in advanced technology, effectively managing inventory, collaborating with suppliers, and engaging employees, businesses can make significant strides in minimizing waste. As the industry continues to evolve, staying committed to sustainability will create a competitive edge while contributing positively to the environment.

To explore the technologies that make it easier to achieve waste reduction in cylindrical print production, explore our high-quality cylindrical printers here.

FAQ

What are the most common types of waste in cylindrical print production?

The most common types of waste include excess materials and ink usage, production errors, energy waste, and unsold inventory.

How can I measure waste in my cylindrical print production process?

You can measure waste by tracking metrics such as material usage, production output rates, energy consumption, and the rate of defective products. This data can help identify areas for improvement.

Can technology really make a difference in reducing waste?

Yes, advanced printing technologies and software solutions can help monitor processes, optimize material use, and reduce errors, all of which contribute to significant waste reduction.

Is employee training essential for waste reduction?

Absolutely! Regular training ensures that employees are up-to-date with industry practices and technologies, enabling them to work efficiently and minimize waste.

What role does supplier collaboration play in reducing waste?

Collaborating with suppliers can enhance the sourcing of sustainable materials, improve packaging practices, and facilitate shared waste management initiatives, all contributing to reduced waste.