How to Use White Ink for High-Contrast Tumbler Prints

Introduction

When creating custom tumblers, the choice of ink is crucial to achieving vibrant and eye-catching designs. While many printers focus on traditional colors, the use of white ink stands out as a game-changer in tumbler printing. Utilizing white ink allows for high-contrast designs, especially on dark surfaces, providing a striking visual that grabs attention. In this blog post, we’ll explore how to effectively use white ink for high-contrast tumbler prints, offering tips, techniques, and insights to elevate your customization game.

Benefits of Using White Ink

White ink offers unique advantages that can transform your tumblers into standout pieces. Here are some of the key benefits:

·

Enhanced Contrast: White ink creates stunning contrasts on dark or colored tumblers, making designs pop.

·

·

Versatility: It can be used as a base coat for other colors, enhancing their vibrancy and depth.

·

·

Creative Freedom: White ink expands your design possibilities, allowing for unique and intricate patterns.

·

·

Durability: Generally, white inks are formulated to withstand wear and tear, ensuring longevity of your designs.

·

Understanding Your Printer

Before diving into the printing process, it's essential to understand the specifics of your tumbler printer. Not all printers are equipped to handle white ink. Here's what to consider:

Choose the Right Printer

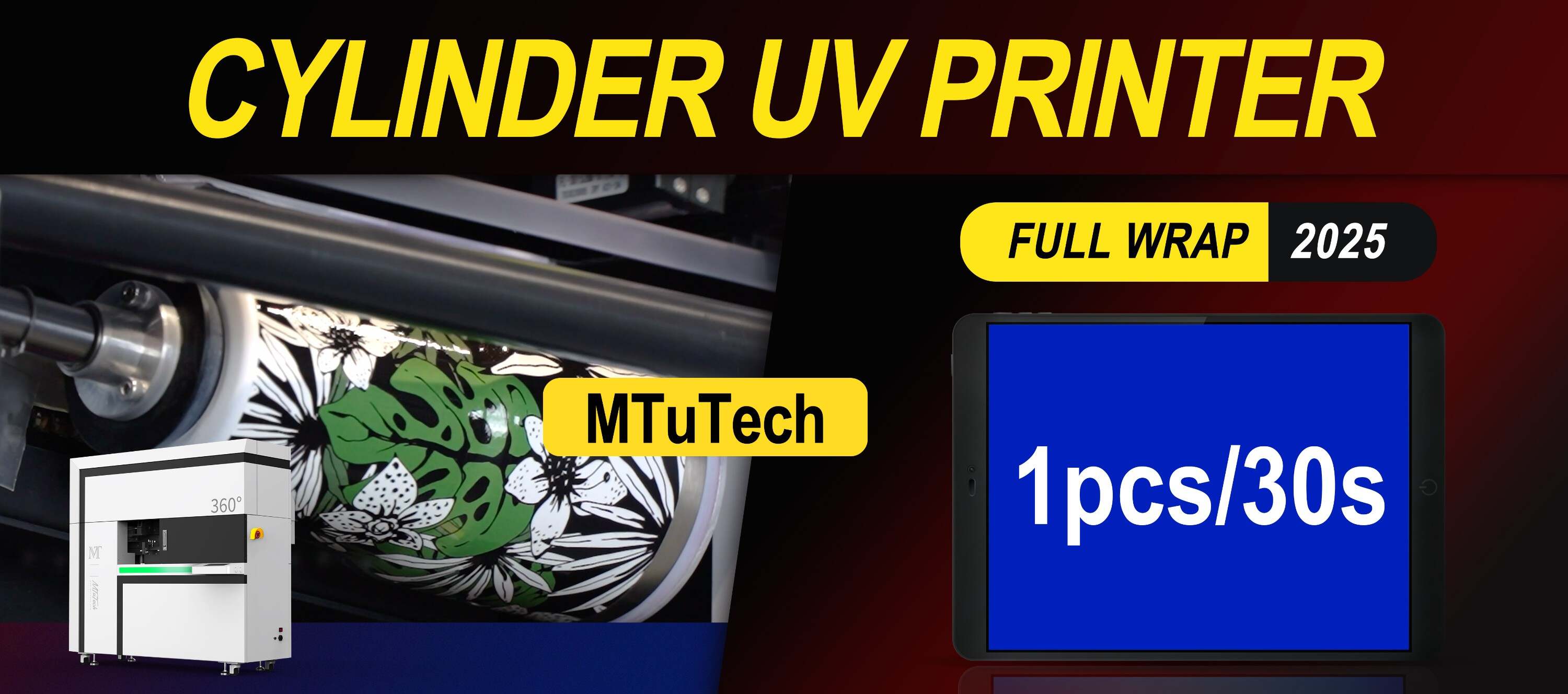

Ensure that your tumbler printer is compatible with white ink printing. Many modern UV and DTG (Direct to Garment) printers offer white ink as a feature.

Know Your Ink Type

Familiarize yourself with the type of white ink your printer uses. There are two main types:

·

Opaque White: Creates a vibrant, solid finish that's ideal for dark substrates.

·

·

Transparent White: Offers a soft effect and is typically used for layering.

·

Preparing Your Design

The design phase is crucial when it comes to printing with white ink. Here’s how to prepare effectively:

Design Considerations

To create high-contrast designs, consider the following:

·

Color Selection: Choose colors that will contrast well with white. Bright colors like reds, blues, and greens will stand out against a white background.

·

·

Layering: Use white ink as a base layer beneath colored inks to increase their brightness and intensity.

·

·

Font and Graphics: Select bold fonts and graphics that can benefit from the high contrast white provides.

·

Using Design Software

Software like Adobe Illustrator, CorelDRAW, or specialized printer software will give you the tools you need to create your tumbler design. When setting up your file:

·

Use vector graphics for crisp edges.

·

·

Set up a separate layer for the white ink.

·

·

Adjust the opacity settings to achieve the desired effects.

·

Printing Process

Once your design is ready, it’s time to move forward with the printing process. Here are the steps to ensure successful tumbler printing using white ink:

Printer Setup

Ensure that your printer is properly set up for white ink printing:

·

Check the ink levels and ensure your white ink cartridge is full.

·

·

Perform any necessary maintenance on your printer ahead of time.

·

·

Load the tumblers securely to prevent movement during printing.

·

Print Layering Technique

When using white ink, the layering technique is crucial for achieving high-quality prints:

·

Base Layer: Start by printing a white base layer on the tumbler. This layer should be applied first and dried completely before moving on.

·

·

Color Layers: Once the base is dry, proceed with printing your colored designs. This allows the colors to maintain their vibrancy against the white background.

·

·

Final Touches: After printing the desired layers, cure the tumblers as per your printer’s specifications to ensure the longevity of the designs.

·

Post-Printing Finishing Techniques

After the printing process, consider these finishing techniques to further enhance your tumbler designs:

Quality Control

Inspect each tumbler for defects post-printing:

·

Check for color consistency.

·

·

Look for any alignment issues or smudges.

·

·

Ensure the white ink is opaque and covers as intended.

·

Curing and Coating

Curing is essential for ensuring that printed designs are durable. Options include:

·

UV Curing: Use a UV light to cure the print immediately.

·

·

Heat Treatment: For certain inks, heat treatment can be an effective way to set the colors.

·

Cleaning and Maintenance

Regular maintenance of your printer will ensure the best performance:

·

Perform routine head cleanings to prevent clogs.

·

·

Keep the printer environment dust-free to avoid contamination.

·

·

Use high-quality inks specifically designed for your printer.

·

Conclusion

The use of white ink in tumbler printing is a brilliant method to create high-contrast, vibrant designs that stand out. By following the steps outlined in this guide—from understanding your printer to post-printing techniques—you can maximize the visual impact of your custom tumblers. Embrace the versatility of white ink to unleash your creativity and deliver stunning results that your customers will love.

If you're looking to enhance your printing capabilities further, explore our high-quality Tumbler printers here for the best options in the market.

FAQ

Can I use white ink on all tumbler surfaces?

White ink generally works best on darker or colored surfaces. However, it can also be used on light surfaces for a softer effect.

How do I prevent the white ink from clogging?

Regularly maintaining your printer, using high-quality inks, and performing routine cleanings will help prevent clogs.

What design software do you recommend for preparing tumbler designs?

Adobe Illustrator and CorelDRAW are both excellent options for creating high-quality designs suitable for tumbler printing.

Is white ink more expensive than regular ink?

White ink can be more expensive, but its benefits in creating vibrant designs often justify the investment.

How long does the curing process take?

The curing time can vary depending on the printer and ink type but typically ranges from a few seconds to a couple of minutes when using UV curing methods.