Packaging as a Marketing Tool: The Role of Cylinder UV Printing

Introduction

In the competitive arena of retail and product marketing, the importance of packaging cannot be overstated. It serves as the first point of physical interaction between your product and the consumer. A unique and eye-catching design helps to attract attention, convey brand values, and influence purchasing decisions. One of the most effective methods of achieving vibrant and detailed designs on packaging is through Cylinder UV printing. In this blog post, we will explore how Cylinder UV printing can enhance your packaging strategy and serve as a powerful marketing tool.

The Significance of Packaging in Marketing

Packaging extends beyond mere aesthetics; it plays a multifaceted role in how a product is perceived. Here are some key aspects of packaging in marketing:

·

Brand Identity: Packaging reflects your brand’s identity and values. Consistency in design helps reinforce brand recognition.

·

·

Consumer Appeal: Attractive packaging can catch the eye and draw in potential consumers amidst a cluttered shelf.

·

·

Information Delivery: Packaging serves as a medium for crucial information about the product, from ingredients to usage instructions.

·

·

Protection: Effective packaging safeguards products from damage during transportation and storage, ensuring they reach consumers in optimal condition.

·

What is Cylinder UV Printing?

Cylinder UV printing, also known as rotary UV printing, is a sophisticated printing technique that utilizes ultraviolet (UV) light to cure or dry inks as they are printed. This method is particularly suitable for cylindrical objects such as bottles, jars, and tubes. The technology allows for rapid production speeds and the ability to print on a variety of substrates, making it an attractive option for brands looking to enhance their packaging aesthetics.

Benefits of Cylinder UV Printing

1. High-Quality Results

Cylinder UV printing excels in producing high-resolution prints. The use of UV light to cure inks results in vibrant color reproduction and intricate details. This quality is crucial for brands that want their packaging to stand out in visually competitive markets.

2. Versatility in Material Usage

This printing technique is compatible with numerous materials, including glass, plastic, and metal. This versatility allows brands to choose the packaging material that best complements their product, further enhancing consumer perception.

3. Environmental Friendliness

Cylinder UV printing is a more eco-friendly option compared to traditional printing methods. UV inks are free from solvents, which makes them less harmful to the environment. Additionally, the quick drying process results in less ink waste.

4. Durability and Longevity

Products packaged using Cylinder UV printing are often more resistant to abrasion, moisture, and UV light than those printed with traditional methods. This durability ensures that packaging maintains its quality throughout the product’s lifecycle, ultimately contributing to a better customer experience.

Features of Cylinder UV Printing

1. Customization Options

One of the standout features of Cylinder UV printing is the potential for customization. Brands can choose from a multitude of colors, finishes, and designs to create a packaging solution that uniquely represents their identity. Options include:

·

Glossy or Matte Finishes: Choose the look that best fits your branding.

·

·

Textured Effects: Add tactile features to elevate the unboxing experience.

·

·

Color Variations: Print vibrant colors that align with brand themes.

·

2. Rapid Turnaround Times

Cylinder UV printing significantly reduces printing times due to its fast curing process. This allows brands to bring products to market quickly, catering to consumer demands without the extended delays associated with traditional printing methods.

3. Capability for Complex Designs

The precision of Cylinder UV printing allows for the incorporation of intricate designs, logos, and graphics that can differentiate a product on the shelf. Brands can utilize this feature to narrate their story through engaging visuals.

Integrating Cylinder UV Printing into Your Packaging Strategy

To effectively leverage Cylinder UV printing as a marketing tool, consider the following steps:

·

Understand Your Audience: Tailor your packaging design to suit the preferences of your target market. Conduct market research to gain insights into colors, designs, and materials that resonate with your consumers.

·

·

Create a Compelling Design: Work with designers who understand the capabilities of Cylinder UV printing. They can help craft a package that is both functional and visually appealing.

·

·

Emphasize Sustainability: If your brand values sustainability, consider incorporating eco-friendly materials and processes into your packaging to appeal to environmentally conscious consumers.

·

·

Incorporate QR Codes: Use Cylinder UV printing to incorporate QR codes that lead consumers to additional information, promotions, or brand stories. This interactivity can enhance consumer engagement.

·

Conclusion

Incorporating Cylinder UV printing into your packaging strategy can significantly elevate your brand’s marketing efforts. By enhancing visual appeal and ensuring durability while adhering to environmental standards, this printing method empowers brands to create memorable packaging that resonates with consumers. In a world where first impressions matter, utilizing innovative printing technologies like Cylinder UV printing can give your product the competitive edge it needs.

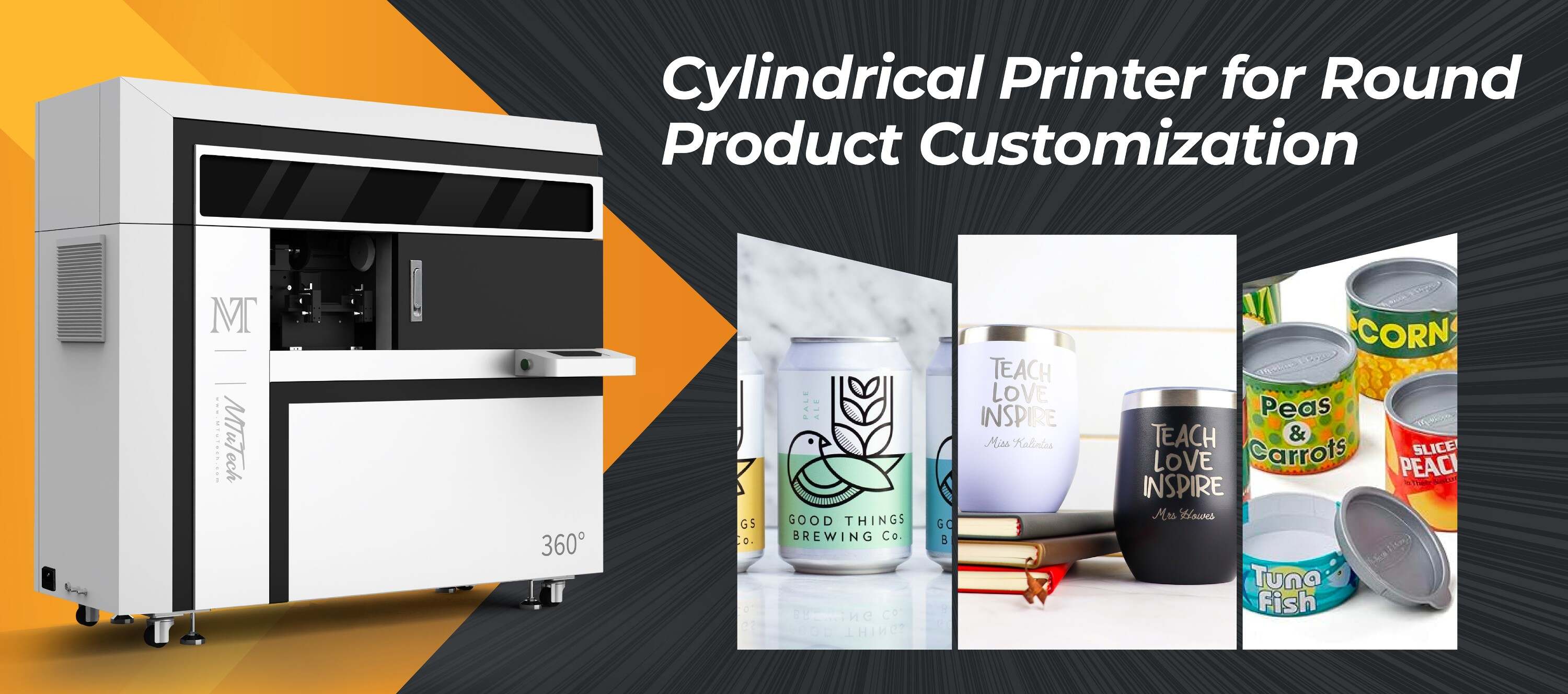

For brands looking to take their packaging to the next level, the right equipment is essential. Explore our high-quality Cylindrical printers here to discover solutions that can meet your unique packaging needs.

FAQ

What types of products can benefit from Cylinder UV printing?

Cylinder UV printing is particularly effective for cylindrical products such as bottles, cans, jars, and tubes. It allows for vibrant graphics and durable packaging, making it suitable for a wide range of industries, including cosmetics, beverages, and food packaging.

Is Cylinder UV printing environmentally friendly?

Yes, Cylinder UV printing is considered more environmentally friendly than traditional printing methods. The process uses UV-curable inks that do not contain solvents, reducing harmful emissions and waste. Additionally, the quick drying time minimizes ink waste.

How does Cylinder UV printing compare to traditional printing methods?

Cylinder UV printing offers several advantages over traditional methods, including faster production speeds, higher print quality, and greater durability. It also allows for intricate designs and is more environmentally sustainable.

Can I customize my packaging design with Cylinder UV printing?

Absolutely! Cylinder UV printing is highly customizable. Brands can choose various colors, finishes, and effects to create a unique and engaging packaging design that aligns with their brand identity.

What is the typical turnaround time for Cylinder UV printing?

The turnaround time for Cylinder UV printing is generally quicker than traditional printing methods due to the rapid curing process. This allows brands to get their products to market faster and keep up with consumer demand.