Preparing Print-Ready Graphics for Seamless Cylindrical Wraps

Preparing Print-Ready Graphics for Seamless Cylindrical Wraps

Introduction

Creating eye-catching graphics for cylindrical wraps can be a challenging task. Unlike traditional flat surfaces, cylindrical objects require special attention to detail to ensure that the final product is both visually appealing and functional. In this blog post, we will break down the essential steps and best practices for preparing print-ready graphics specifically designed for seamless cylindrical wraps. Whether you're a designer, a print professional, or a business owner looking to optimize your branding, this guide will provide valuable insights.

The Importance of Proper Preparation

When it comes to cylindrical wraps, the quality of the graphics and the preparation process can significantly impact the final output. If the graphics are not correctly prepared, it can lead to issues like stretching, skewing, or misalignment when the material is applied to the cylinder. This could result in a poor-quality product that fails to represent your brand effectively.

Eye-Catching Visuals

High-quality graphics can make a substantial difference in attracting customers. A well-designed wrap can enhance brand visibility and appeal, ultimately driving sales.

Cost-Effectiveness

Proper preparation can save you money by reducing waste, minimizing the need for reprints, and ensuring a quick turnaround time. Investing time in the initial steps can lead to long-term savings.

Steps to Prepare Print-Ready Graphics

To create graphics that translate well onto cylindrical wraps, follow these essential steps:

Step 1: Understand the Dimensions

Before diving into graphic design, it is crucial to understand the dimensions of the object you are wrapping. Measure the height and diameter of the cylinder accurately. These measurements will help you create a design that fits seamlessly around the object.

Step 2: Use the Right Software

Select graphic design software that supports vector formats, such as Adobe Illustrator or CorelDRAW. These programs are ideal for creating print-ready graphics and can help you maintain high image quality.

Step 3: Set the Correct Canvas Size

Establish your canvas size in accordance with the dimensions of the cylinder. To calculate the canvas width, use the formula: Cylinder Circumference = Diameter x π. Setting the correct canvas size in advance will help you visualize how the wrap will look once applied.

Step 4: Design for the Cylinder

When designing your graphics, keep in mind the curvature of the cylinder. Utilize the following tips for optimal design:

·

Position Important Elements Strategically: Place key branding elements, such as logos and messages, where they are most likely to be seen when the product is in use.

·

·

Consider Visual Flow: Use lines and shapes that follow the curvature of the object, creating a natural flow that engages viewers.

·

·

Avoid Small Text: Small text may become distorted once applied and may not be legible from a distance; stick to bold, easy-to-read fonts.

·

Step 5: Prepare for Bleed and Trim

Add a bleed area to your graphic design to ensure the design extends beyond the edges of the final print size. This will prevent any white spaces from showing when the graphic is wrapped around the cylinder. Typically, a bleed of at least 0.125 inches (3mm) is recommended.

Step 6: Use High-Resolution Images

Graphics should be created using high-resolution images, ideally at least 300 DPI (dots per inch). This ensures that the printed wrap maintains clarity and sharpness, avoiding blurry or pixelated images once printed.

Step 7: Convert to CMYK

Most printing processes work with CMYK color modes rather than RGB. Convert all colors in your design to CMYK to ensure that the printed colors match your expectations and look vibrant on the final product.

Step 8: Quality Check Before Printing

Before sending your design to print, conduct a thorough quality check. Look for pixelation in images, spelling errors in text, and overall alignment. Using a test print on a smaller scale can also be beneficial to visualize how the design will look on the final product.

Step 9: Collaborate with Your Printer

Consult with your printing service about their specific requirements. Different printers may have unique specifications regarding file formats, dimensions, and color profiles. Discussing these details in advance can ensure a smoother printing process.

Best Practices for Seamless Cylinder Wraps

To further enhance the effectiveness of your graphics preparation, consider these best practices:

Use Templates

Many printing companies provide templates for different cylindrical objects. Using these templates can save time and ensure your designs are perfectly sized and formatted.

Test Fit the Design

Before finalizing your design, create a mock-up or a prototype wrap. This can help you visualize how the wrap will fit and look on the actual product, allowing for any necessary adjustments.

Account for Stretch and Shrinkage

Depending on the material used for the wrap, there may be some stretch or shrinkage during the application process. Design your graphics keeping this in mind to avoid losing important elements in the final application.

Conclusion

Creating print-ready graphics for seamless cylindrical wraps requires careful preparation and a keen eye for design. By following the steps outlined in this article, you can ensure that your graphics not only look great but also function well when applied to cylindrical surfaces. Whether you're wrapping bottles, cans, or any other cylindrical object, the right approach will enhance your brand's visibility and impact.

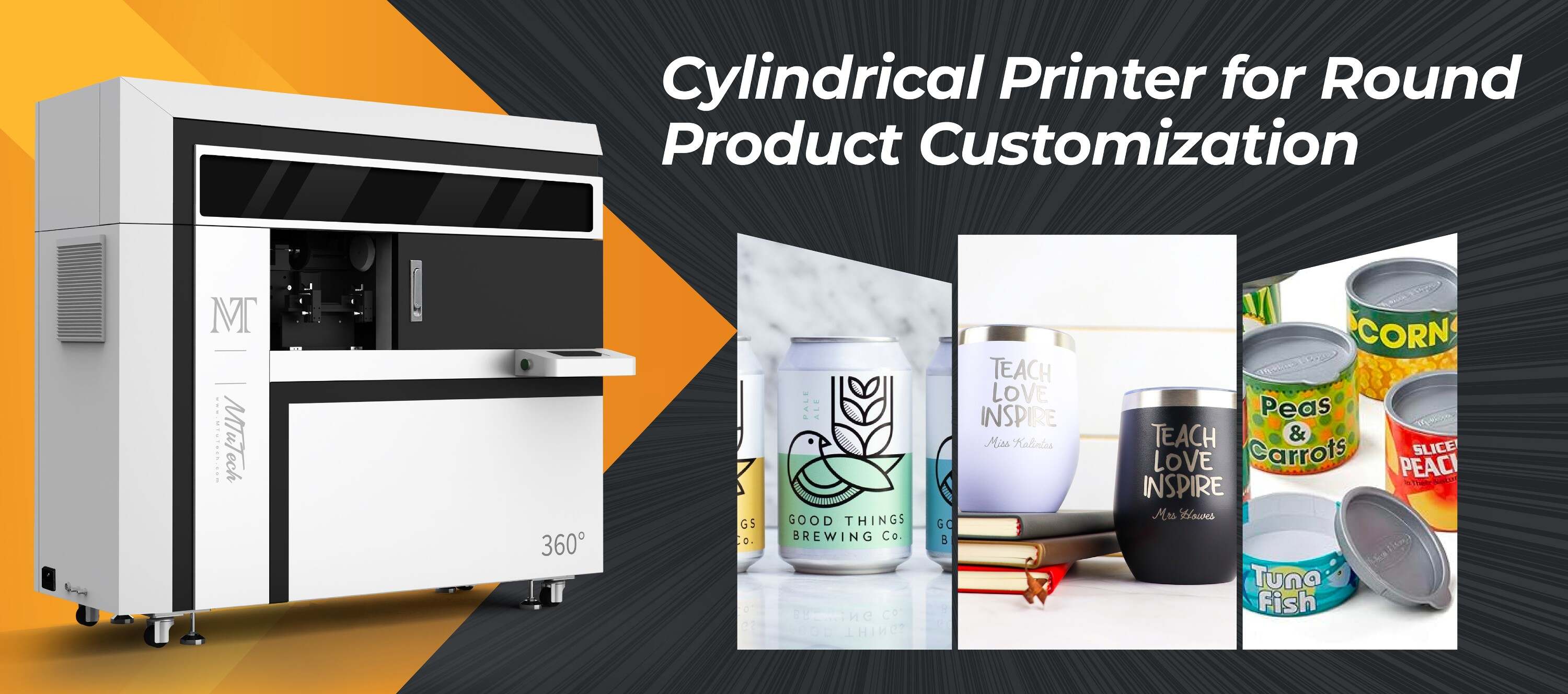

If you're interested in exploring options to take your printing to the next level, explore our high-quality cylindrical printers here.

FAQ

What file formats are best for cylindrical wrap printing?

The preferred file formats for cylindrical wrap printing are typically PDF, AI (Adobe Illustrator), or EPS. These formats retain high quality and are suitable for printing.

How can I ensure my colors print accurately?

To ensure color accuracy, always work in CMYK mode when designing for print. Consult with your printing service for color matching options and consider getting a sample print if color is critical to your project.

Is it necessary to hire a professional designer for graphics preparation?

While hiring a professional designer can enhance the quality of your designs, it is not strictly necessary. Many businesses find success in preparing their graphics by following best practices and utilizing design software effectively.

What materials are commonly used for cylindrical wraps?

Cylindrical wraps can be made from various materials, including vinyl, paper, and adhesive film. The choice of material will depend on the application and durability requirements.

Can I use images from the internet in my designs?

Using images from the internet requires caution. Ensure that you have the appropriate licenses or permissions to use images, especially for commercial purposes, as copyright infringement can lead to legal issues.