Print on Odd-Shaped Tumblers? Here’s the Solution

Print on Odd-Shaped Tumblers? Here’s the Solution

Introduction

In recent years, custom drinkware has become a significant trend among manufacturers and retailers. Among these, tumblers are exceptionally popular due to their versatility and usability. However, the market has evolved, and so have the shapes of tumblers. With odd-shaped tumblers gaining traction, one question arises for businesses and artists alike: how do you print on these unique surfaces? In this article, we will explore the various options and technologies available for printing on odd-shaped tumblers.

The Rise of Odd-Shaped Tumblers

Odd-shaped tumblers are tumblers that deviate from standard forms. They could include unique curves, shapes, or designs that make them stand out in the market. As consumers increasingly seek novelty and personalization, these tumblers offer a great opportunity for customization.

Why Choose Odd-Shaped Tumblers?

·

Individuality: Consumers love products that reflect their personal style.

·

·

Market Differentiation: Unique shapes can differentiate a brand in a crowded market.

·

·

Versatile Uses: Great for promotional items, gifts, or personal use.

·

Challenges of Printing on Odd-Shaped Tumblers

While odd-shaped tumblers are appealing, printing on them can be challenging due to their unique contours and surfaces. Standard printing techniques may not apply effectively, leading to uneven prints, distortion, or incomplete designs. Here are some key challenges:

·

Surface Area: Irregular shapes may have uneven surface areas that complicate ink application.

·

·

Adhesion: Unique materials and finishes require specific inks to ensure proper adhesion.

·

·

Alignment: Achieving proper alignment becomes tricky with non-standard shapes.

·

Innovative Printing Solutions

Fortunately, advancements in printing technology have made it easier than ever to print on odd-shaped tumblers. Here are some effective solutions:

1. UV Printing

UV printing utilizes ultraviolet light to cure (dry) the ink as it is printed on the tumbler. This technology is suitable for various materials, including glass, metal, and ceramics. It provides vibrant, high-quality prints that are durable and resistant to fading.

·

Benefits: Fast curing times, high-quality results, and ability to print on various materials.

·

·

Customization: Allows for intricate designs and color accuracy.

·

2. Heat Transfer Printing

This technique involves printing a design onto transfer paper and then using heat and pressure to apply it to the tumbler. Heat transfer printing works effectively on odd shapes and can cover large areas.

·

Benefits: Cost-effective for small runs, ideal for multi-color designs.

·

·

Flexibility: Great for creating one-off designs or smaller batches.

·

3. Sublimation Printing

Sublimation involves transferring dye onto a surface using heat. This method works best on tumblers coated with a special polymer coating, which allows the dye to become part of the material, resulting in vibrant and long-lasting designs.

·

Advantages: Produces full-color graphics and photos directly on the tumbler’s surface.

·

·

Results: The designs are very durable, resistant to scratching, fading, and peeling.

·

Choosing the Right Tumbler Printer

To dive into the world of printing on odd-shaped tumblers, selecting the right printing machine is critical. Here are some aspects to consider:

·

Size and Dimensions: Ensure the printer can accommodate the unique dimensions of your tumblers.

·

·

Print Quality: Look for printers that can handle high-resolution designs.

·

·

Versatility: Choose machines that can handle various shapes and materials.

·

·

Speed: Assess the printing speed if you plan to handle bulk orders.

·

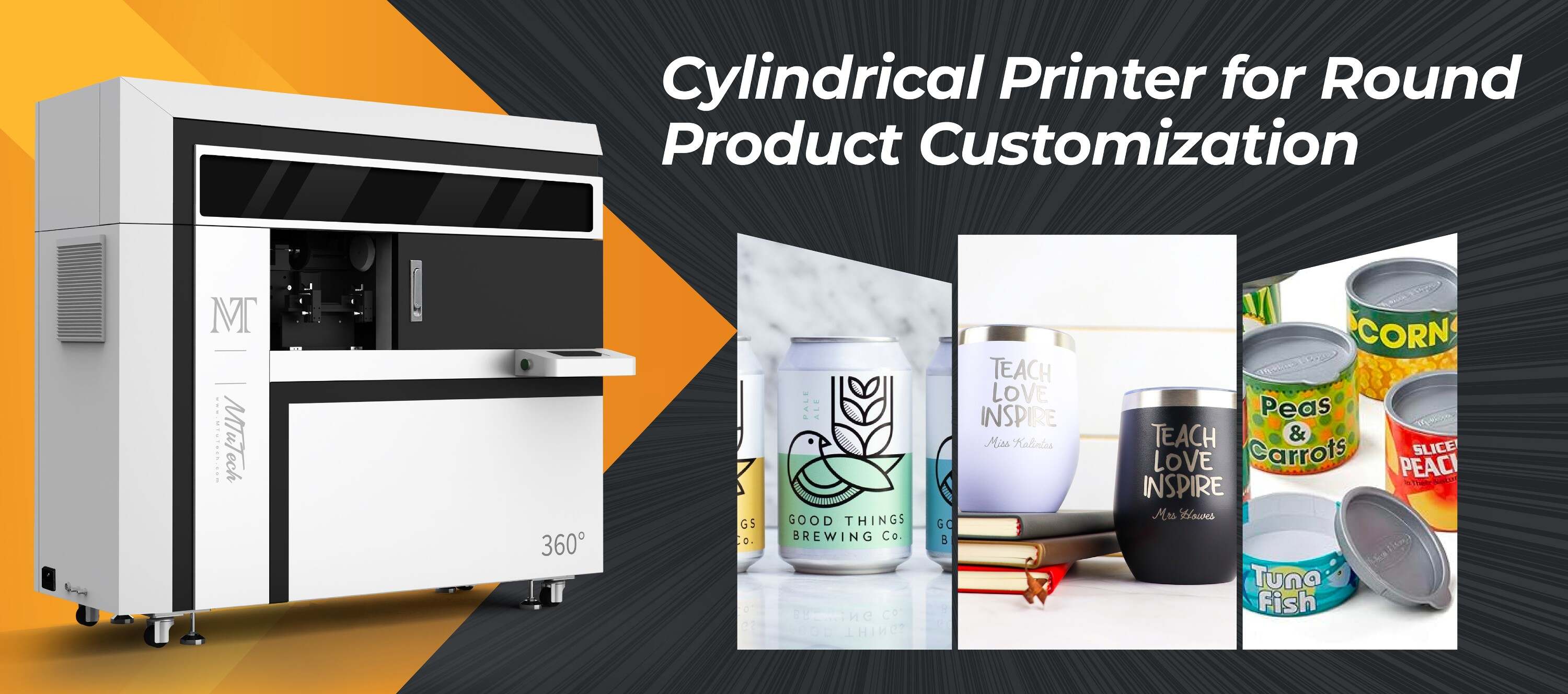

For businesses looking for high-quality beverage printing solutions, explore our high-quality Tumbler printers here and discover the perfect match for your needs.

Tips for Successful Printing on Odd-Shaped Tumblers

To maximize your printing results, consider the following tips:

·

Testing: Always conduct test prints to ensure the desired effect before a full run.

·

·

Adjust Settings: Modify printer settings according to the shape and material of the tumbler.

·

·

Inks and Coatings: Use appropriate inks that are compatible with specific tumbler materials.

·

Conclusion

Customizing odd-shaped tumblers provides an excellent opportunity for businesses to offer unique products that resonate with consumers. While printing on these unconventional shapes poses challenges, advanced printing technologies and strategic choices can yield impressive results. By selecting the right printing method and techniques, you can turn these tumblers into stunning, personalized items that stand out in the marketplace. Embrace the challenge of printing on odd-shaped tumblers, and unlock a new level of creativity for your business!

FAQ

What types of printers are best for printing on odd-shaped tumblers?

UV printers, heat transfer printers, and sublimation printers are among the best choices for odd-shaped tumblers, offering durability and quality customization options.

Can I print on tumblers made of different materials?

Yes, different printing methods can be used on various materials, including stainless steel, plastic, and glass, provided that the appropriate inks and settings are used.

What design elements should I consider for odd-shaped tumblers?

Focus on designs that complement the shape, maintain clarity for smaller details, and consider the color contrasts to enhance the visual appeal.

How can I ensure the durability of the print on my tumblers?

Using high-quality inks suitable for the tumbler material and applying a UV protective coat or choosing a sublimation method can significantly enhance print durability.