Printing Transparent Cylindrical Items with Perfect Color Density

Introduction

Printing on transparent cylindrical items presents unique challenges and opportunities. From personalized gifts to specialized retail items, achieving perfect color density on transparent materials is crucial for aesthetic appeal. This blog post will explore the techniques, benefits, and essential features of printing transparent cylindrical objects with high-quality color density, enabling businesses to enhance their branding and product offerings.

Understanding the Challenges

Printing on transparent cylindrical surfaces introduces a set of challenges that need to be addressed to achieve desired outcomes. These challenges include:

·

Surface Texture: Transparent materials often have varied textures that affect ink adhesion.

·

·

Ink Transparency: Achieving vibrant colors can be difficult as the transparency of the substrate impacts the final appearance.

·

·

Shape Complexity: The curvature of cylindrical items can complicate the printing process, making it harder to distribute ink evenly.

·

Benefits of Printing on Transparent Cylindrical Items

Despite these challenges, printing on transparent cylindrical items offers significant benefits:

·

Unique Aesthetic Appeal: Transparent items provide a modern, sleek look that can enhance product visibility.

·

·

Diverse Applications: They can be used in various industries including retail, hospitality, and custom gifts.

·

·

Enhanced Brand Visibility: Beautiful color prints attract attention and create a lasting impression on customers.

·

Essential Features for Perfect Color Density

To successfully print on transparent cylindrical items with perfect color density, certain features and technologies make a significant difference:

1. High-Quality Inks

Using high-quality inks designed specifically for transparent substrates ensures vibrant colors and long-lasting results. UV-curable inks are particularly effective as they provide excellent adhesion to non-porous surfaces and are resistant to fading.

2. Advanced Printing Technologies

Utilizing advanced printing technology such as UV printing or direct-to-object (DTO) printing can enhance the color density and clarity of the printed images. These technologies cure the ink instantly, preventing any smudging or running during the printing process.

3. Correct Printer Settings

Proper calibration of the printer settings is crucial. This includes adjustments to ink saturation, resolution, and speed to ensure an even distribution of color across the cylindrical surface.

4. Surface Preparation

Preparing the surface of the cylindrical item can dramatically improve ink adhesion. Cleaning the surface and possibly applying a primer or coating can help achieve better results.

5. Testing and Prototyping

Before final production, conducting tests and creating prototypes can help in assessing color density and overall appearance. This process allows for adjustments to be made before committing to a larger print run.

Steps to Print Transparent Cylindrical Items

Here’s a step-by-step process to successfully print on transparent cylindrical items:

Step 1: Choose the Right Printer

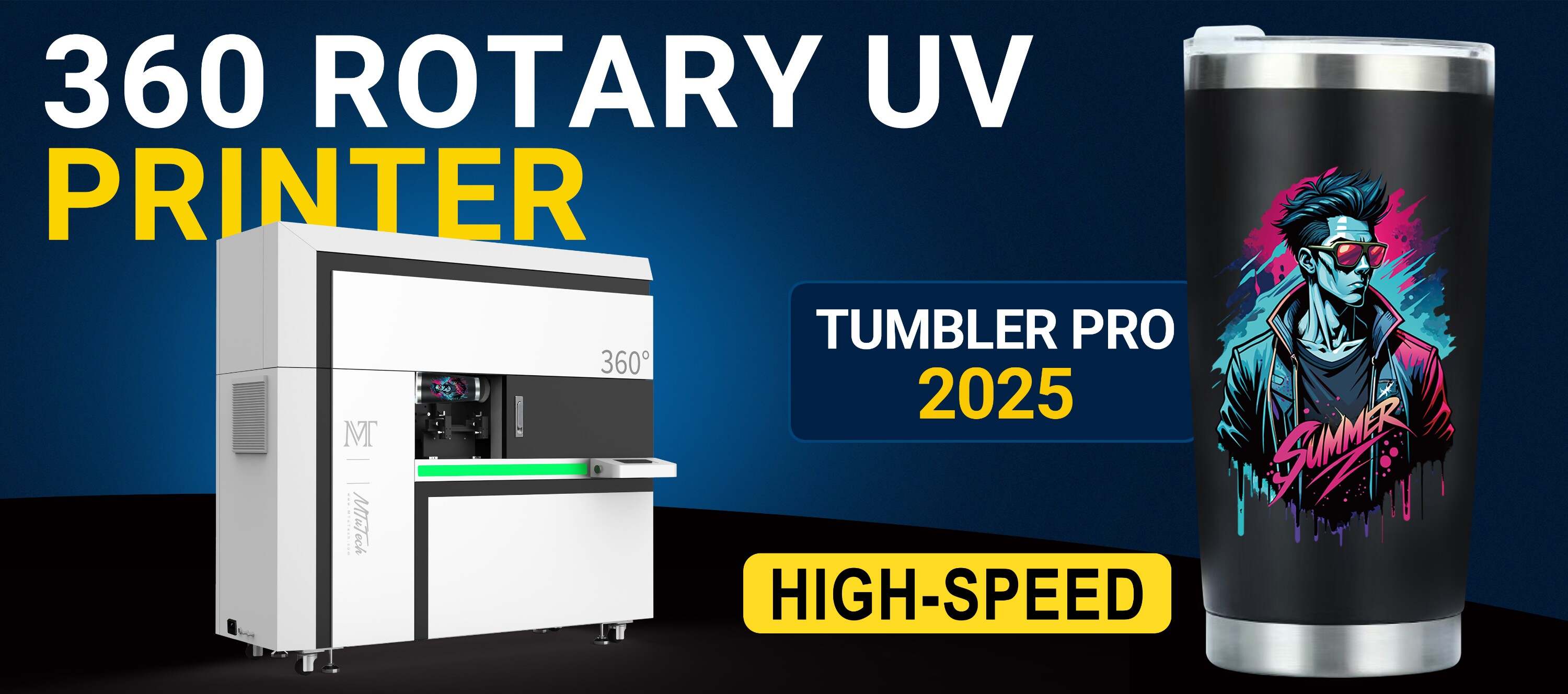

Select a printer specifically designed for cylindrical printing tasks. Explore our high-quality Cylindrical printers here that cater to your specific needs.

Step 2: Prepare Your Design

Create a visually compelling design that considers the curvature and surface of the item. Make sure the design aligns correctly when wrapped around the object.

Step 3: Surface Preparation

Clean the item thoroughly to remove any dust or oils. A well-prepared surface ensures proper ink adhesion and promotes vibrant results.

Step 4: Configure Printer Settings

Adjust printer settings according to the type of substrate and desired end result. This includes selecting the right ink type, print resolution, and curing settings.

Step 5: Print and Cure

Start the printing process and monitor closely. Ensure that the curing process effectively solidifies the ink without distorting the print.

Quality Control and Final Touches

After printing, conduct a thorough inspection. Check for consistent color density, clarity of the design, and overall quality. Make any necessary adjustments to printer settings for future print runs based on this inspection.

Conclusion

Printing on transparent cylindrical items allows businesses to showcase their creativity while providing unique product offerings. By understanding the challenges and leveraging the right technologies, one can achieve perfect color density that makes a lasting impression. From personal gifts to professional branding, mastering this technique can elevate your printing game and cater to the demands of various industries.

FAQ

What types of inks are best for transparent cylindrical printing?

UV-curable inks are the best choice for transparent cylindrical printing as they provide excellent adhesion, vibrant colors, and resistance to fading.

Can I print on all types of transparent materials?

Not all materials are suitable for printing, but many common transparent plastics and glass can be printed on with the right preparation and ink types.

What is the role of surface preparation in printing?

Surface preparation is crucial as it enhances ink adhesion and overall print quality, ensuring vibrant colors and a professional appearance.

Are there specific printers designed for cylindrical items?

Yes, there are specialized printers designed for printing on cylindrical items, such as UV printers and rotary printing systems, which facilitate high-quality prints on complex shapes.

How can I ensure color accuracy in my prints?

Use calibrated monitor settings for design creation, choose the right printer and ink type, and conduct test prints to assess color accuracy before final production.

By following these steps and ensuring the use of the right technologies and processes, businesses can effectively master the art of printing on transparent cylindrical items with exceptional color density that captivates customers.