Sublimation vs UV Tumbler Printing – What Clients Prefer

In the realm of personalized drinkware, sublimation and UV printing are two of the most popular choices for creating vibrant, durable designs on tumblers. With the booming custom tumbler market, understanding the differences between these two printing methods can help clients make informed decisions that align with their specific needs. This blog will delve into the features, benefits, and preferences surrounding sublimation and UV tumbler printing.

Introduction

The customization of tumblers has gained significant traction over the years. From personalized gifts to branded merchandise, the demand for unique tumbler designs is ever-increasing. Sublimation and UV printing stand out because of their quality and durability, but each method has its unique advantages. As businesses and consumers venture into the world of custom drinkware, knowing the difference between sublimation and UV printing becomes crucial.

Understanding Sublimation Printing

What is Sublimation Printing?

Sublimation printing is a process that involves transferring dye onto materials using heat. This method works best on polyester-coated surfaces or materials that contain a high polyester content. When heat is applied, the dye turns into gas, permeates the substrate, and solidifies back into a solid, creating a permanent, vibrant design.

Benefits of Sublimation Printing

·

Vibrant Colors: Sublimation printers produce stunning graphics and vivid colors that are difficult to achieve with other printing methods.

·

·

Durability: The dye becomes a part of the material, making it resistant to scratching, peeling, and fading.

·

·

Full-Color Designs: Allows for intricate designs, including photographic images, which can be printed seamlessly over the entire tumbler surface.

·

·

Environmentally Friendly: The inks used in sublimation are often water-based, making them a more eco-friendly option.

·

Exploring UV Tumbler Printing

What is UV Printing?

UV printing utilizes ultraviolet lights to cure or dry the printing ink as it is printed. This method works on various surfaces, including glass, metal, plastic, and more. UV printers allow for high-quality, vibrant designs using a range of inks, and the curing process ensures that the ink adheres strongly to the tumbler surface.

Benefits of UV Tumbler Printing

·

Versatile Material Compatibility: UV printing can be used on a wider variety of materials compared to sublimation.

·

·

Immediate Results: The curing process means that tumblers can be used immediately after printing, speeding up the production time.

·

·

Outdoor Durability: UV prints are highly resistant to fading and damage from UV light, making them ideal for outdoor use.

·

·

Customizable Thickness: Users can print designs with a raised texture by adjusting the layers of ink, allowing for unique tactile experiences.

·

Comparing Sublimation and UV Tumbler Printing

Quality and Longevity

When comparing sublimation and UV printing, the quality and longevity of the prints are crucial considerations:

·

Sublimation prints are known for their vivid colors and durability, with designs that can last for years without fading.

·

·

UV prints also offer robust durability, particularly for outdoor usage, but the vibrant color range may be slightly less than that of sublimation prints.

·

Customization Options

Sublimation allows for full-color prints and intricate designs that wrap around the tumbler. On the other hand, UV printing also supports a variety of designs but is particularly advantageous for those seeking raised textures and specific effects. Both methods offer their unique advantages in customization:

·

Sublimation: Best for full color and photographic images.

·

·

UV Printing: Excellent for textured effects and multi-material applications.

·

Production Speed

For businesses, production speed can significantly influence the choice of printing method:

·

Sublimation printing often requires more setup time, as it involves heat presses and careful material selection.

·

·

UV printing provides almost immediate results; as soon as the ink is cured, the tumbler is ready for use, which can be a major advantage in fast-paced environments.

·

Client Preferences: What Drives the Choice?

Determining client preferences regarding sublimation vs. UV tumbler printing often comes down to several factors, including:

·

Type of Product: Clients looking for high-quality photographic images may gravitate towards sublimation, while those interested in a variety of materials may prefer UV printing.

·

·

Intended Use: Those wanting tumblers for outdoor usage or commercial purposes might opt for UV printing due to its resistance to weather conditions.

·

·

Budget and Volume: For bulk orders, the rapid production speed of UV printing may appeal to businesses needing to fulfill large orders quickly.

·

Conclusion

Both sublimation and UV tumbler printing present outstanding benefits, making them popular choices among clients. Sublimation is renowned for its vibrant and durable designs, making it perfect for intricate graphics and personal touches. Conversely, UV printing offers versatility and speed, catering to a wide range of materials and design preferences. Ultimately, the choice between the two will depend on client needs, the nature of the designs, and intended applications.

To make an informed decision, clients should consider their specific requirements, including design preferences, material compatibility, and production timelines. As the industry evolves, staying updated on advancements in both sublimation and UV printing technologies will play a crucial role in meeting client needs.

FAQ

Is sublimation printing suitable for all materials?

No, sublimation printing is primarily effective on polyester-coated materials or items that contain a high proportion of polyester. Other materials may not yield the same vibrant results.

Can UV printing be resistant to outdoor conditions?

Yes, UV printing is designed to be highly durable and resistant to outdoor conditions, including UV light exposure, making it a great choice for outdoor drinkware.

What is the best printing method for intricate designs?

Sublimation printing is often preferred for intricate designs due to its ability to produce detailed and full-color prints that can wrap around the tumbler.

How does the cost compare between sublimation and UV printing?

The cost can vary based on setup and material. Generally, sublimation may involve additional setup fees, especially for smaller runs, while UV printing may be more cost-effective for larger volumes due to its speed.

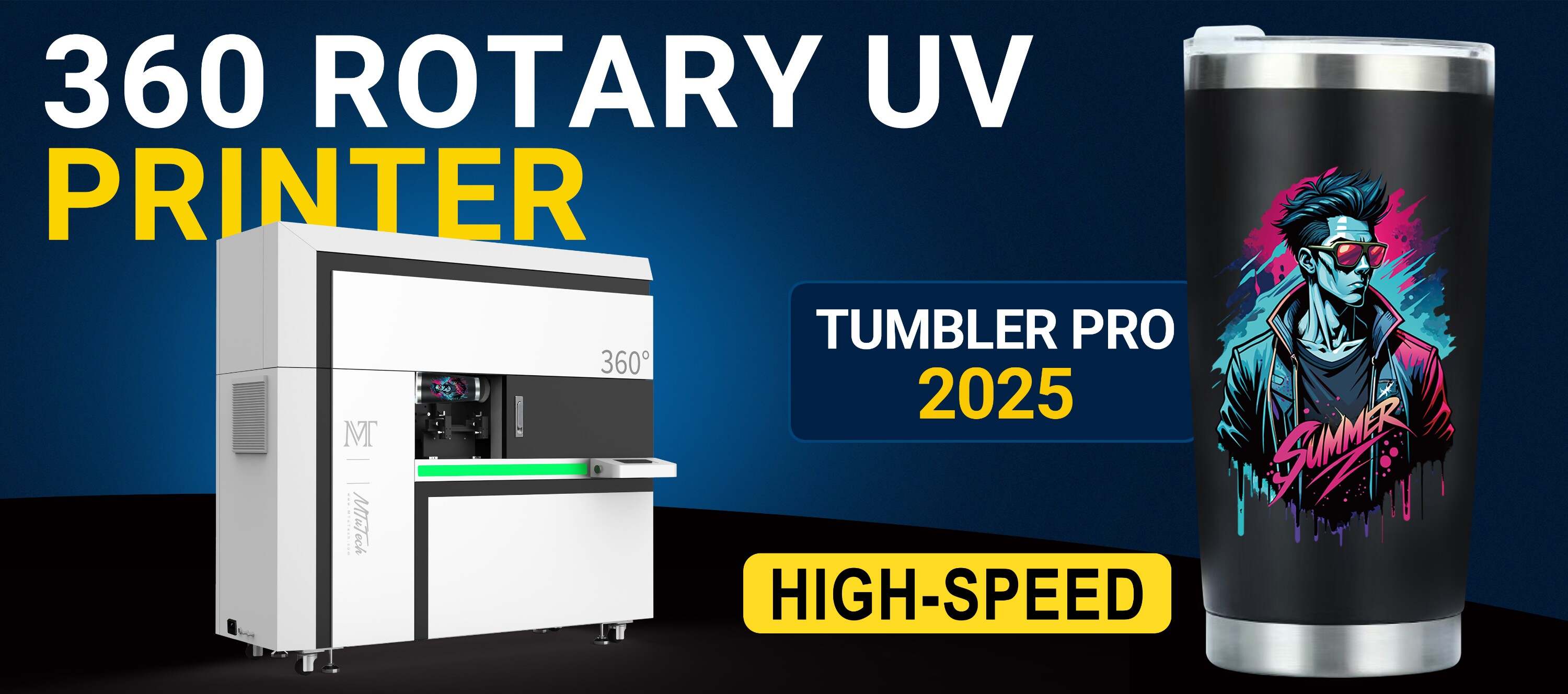

Where can I find high-quality tumbler printers?

For businesses looking to invest in high-quality printing technology, explore our high-quality tumbler printers here to meet your needs.