The Benefits of UV LED Technology in Cylinder UV Printers

The Benefits of UV LED Technology in Cylinder UV Printers

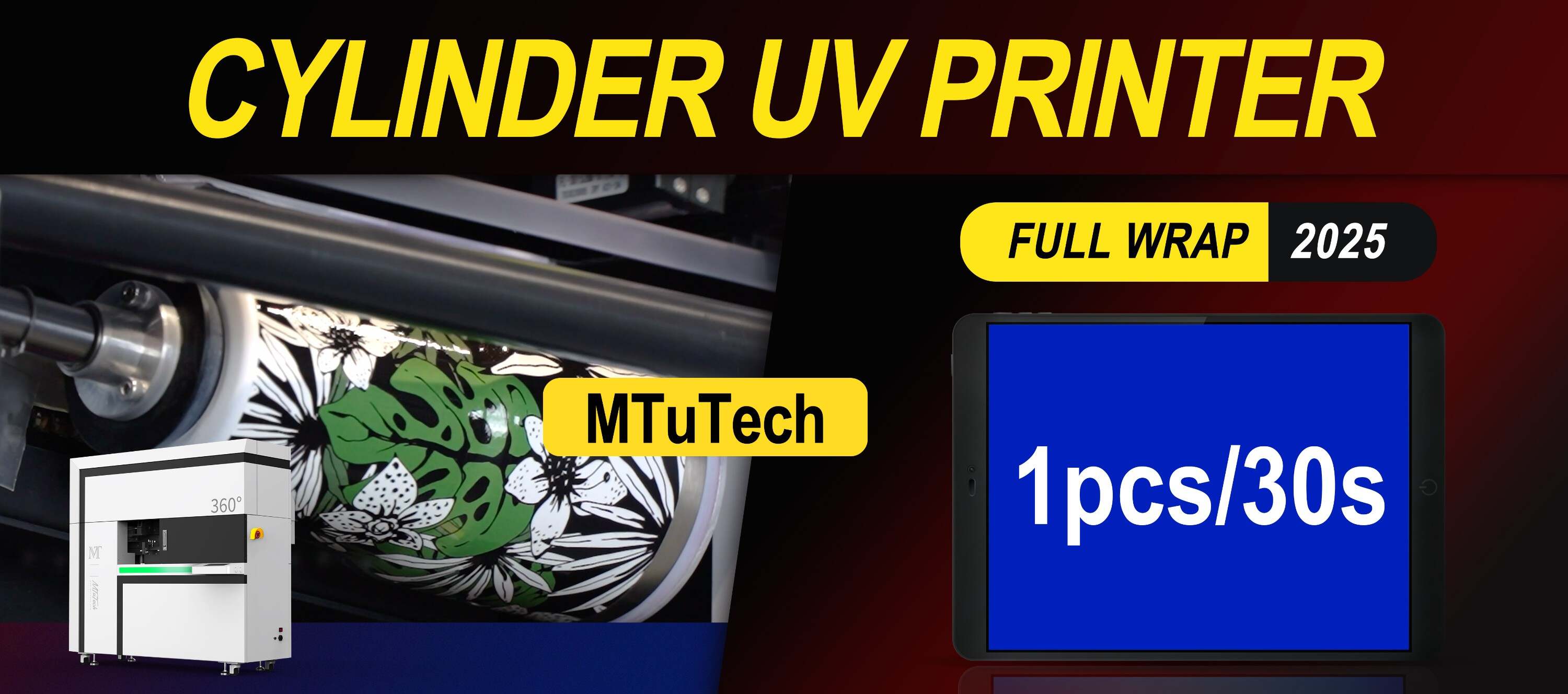

The evolution of printing technology has been marked by significant advances, and one of the most important innovations in recent years is the advent of UV LED technology in cylinder UV printers. This cutting-edge technology has revolutionized the way we print on cylindrical surfaces, offering a variety of benefits that enhance efficiency, quality, and sustainability. UV LED printers have gained popularity across various industries, from packaging and promotional items to custom products and more, thanks to their ability to produce high-quality prints while also offering environmental advantages.

In this blog, we’ll explore the benefits of UV LED technology in cylinder UV printers, highlighting how it improves printing processes and why it’s a great investment for businesses looking to stay ahead of the curve.

What is UV LED Technology?

UV LED technology refers to the use of light-emitting diodes (LEDs) to emit ultraviolet (UV) light that cures the ink on the printing substrate. UV LEDs produce a more concentrated, targeted beam of UV light compared to traditional UV lamps, resulting in a faster curing process with lower energy consumption.

In cylinder UV printers, UV LED lamps replace traditional mercury-based UV curing lamps, providing several key advantages. These printers use UV LED light to cure the inks immediately after they are applied to the material, which is essential for achieving fast, high-quality, and durable prints.

Benefits of UV LED Technology in Cylinder UV Printers

1. Energy Efficiency

One of the most significant advantages of UV LED technology is its energy efficiency. Traditional UV lamps require significant amounts of energy to heat up and operate, whereas UV LED lamps consume far less power. This reduction in energy consumption helps businesses lower their operational costs and reduces their environmental footprint.

UV LED printers use a direct and highly efficient energy source, meaning that they are more energy-efficient and require less power than traditional UV lamps. This is especially beneficial for companies looking to cut costs and reduce their carbon footprint without compromising on print quality.

2. Instant Curing and Faster Production Speeds

UV LED technology enables instant curing of inks, meaning that the printed material is immediately ready for handling, packaging, or further processing. Unlike traditional UV printing, where the ink takes time to dry and cure, UV LED printers cure the ink instantly under UV light.

This rapid curing process improves production speeds and allows businesses to complete jobs faster, which is especially valuable in high-demand environments where time is critical. By reducing the drying time, businesses can increase throughput, lower lead times, and improve overall production efficiency.

3. Longer Printhead Life and Lower Maintenance Costs

UV LED lamps have a significantly longer lifespan compared to traditional UV lamps. While conventional UV lamps may need to be replaced every few thousand hours of use, UV LED lamps can last much longer—often tens of thousands of hours. This means businesses can save on maintenance costs and reduce the downtime associated with replacing bulbs.

Additionally, UV LED printheads are more durable and less prone to wear and tear compared to traditional UV lamps. This makes UV LED printers a more reliable, long-term investment for businesses that require consistent, high-quality output.

4. Environmental Friendliness

The environmental benefits of UV LED technology are one of the key reasons it’s gaining traction in the printing industry. UV LED printers do not contain the hazardous materials often found in traditional UV lamps, such as mercury, which is harmful to the environment.

Furthermore, UV LED lamps do not emit ozone or heat, making them safer for both operators and the environment. This reduces the need for costly ventilation systems, as well as the risk of harmful emissions in the production area. The use of UV LED inks also reduces energy consumption and promotes greener production practices.

5. Better Print Quality and Durability

UV LED printers offer excellent print quality, producing sharp, vibrant, and detailed prints on cylindrical surfaces. The use of LED lights ensures that the ink adheres evenly and cures uniformly, reducing the risk of inconsistencies in print quality.

The cured UV inks also offer better durability compared to traditional inks. UV LED-printed products are highly resistant to wear, UV light, chemicals, and other external factors. This makes them ideal for products that will be exposed to harsh environments, such as automotive parts, packaging materials, and outdoor promotional items.

6. Cooler Printing Process

Unlike traditional UV lamps, which generate a significant amount of heat during the curing process, UV LED lamps remain cool during operation. This means that the printed material is not exposed to excessive heat, which could damage the substrate or distort the print.

The cooler curing process is especially beneficial when printing on heat-sensitive materials, such as plastics or delicate surfaces, which could warp or melt under traditional UV curing lamps. With UV LED technology, businesses can print on a wider range of materials without worrying about heat-related damage.

7. Compact and Space-Saving Design

UV LED curing systems are more compact than traditional UV curing lamps. This makes them ideal for businesses with limited space, as they take up less room on the production floor. The smaller size of UV LED systems also means that they can be easily integrated into existing production lines without requiring significant changes to the setup.

This compact design allows businesses to maximize their workspace while still benefiting from the high-quality prints that UV LED technology provides.

8. Low Heat Emission and Better Workplace Conditions

UV LED lamps emit significantly less heat than traditional UV lamps, creating a more comfortable and safer work environment. This helps maintain optimal conditions for both the printer and the operator. In traditional UV printing, high heat emissions can cause discomfort, require additional cooling systems, and potentially damage sensitive materials.

By reducing heat emissions, UV LED printers offer a safer, more comfortable, and more productive environment for operators, contributing to a better workplace overall.

Conclusion

UV LED technology has proven to be a game-changer for cylinder UV printers, offering businesses a wide range of benefits, including energy efficiency, faster production speeds, lower maintenance costs, and environmental sustainability. By adopting UV LED printers, companies can achieve high-quality, durable prints while reducing their operational costs and environmental impact.

The many advantages of UV LED technology make it an excellent investment for businesses looking to stay ahead in the competitive printing industry. With its ability to improve productivity, reduce downtime, and enhance print quality, UV LED technology is shaping the future of cylinder UV printing.

To learn more about how UV LED technology is transforming custom printing solutions, check out [this link](https://www.mtutech.com/Blogfor360RotaryUVPrinter/Cylinder-UV-Printer-Transforming-Custom-Printing-Solutions-759.html).