The Evolution of Ink Formulations in Cylindrical Printing

Introduction

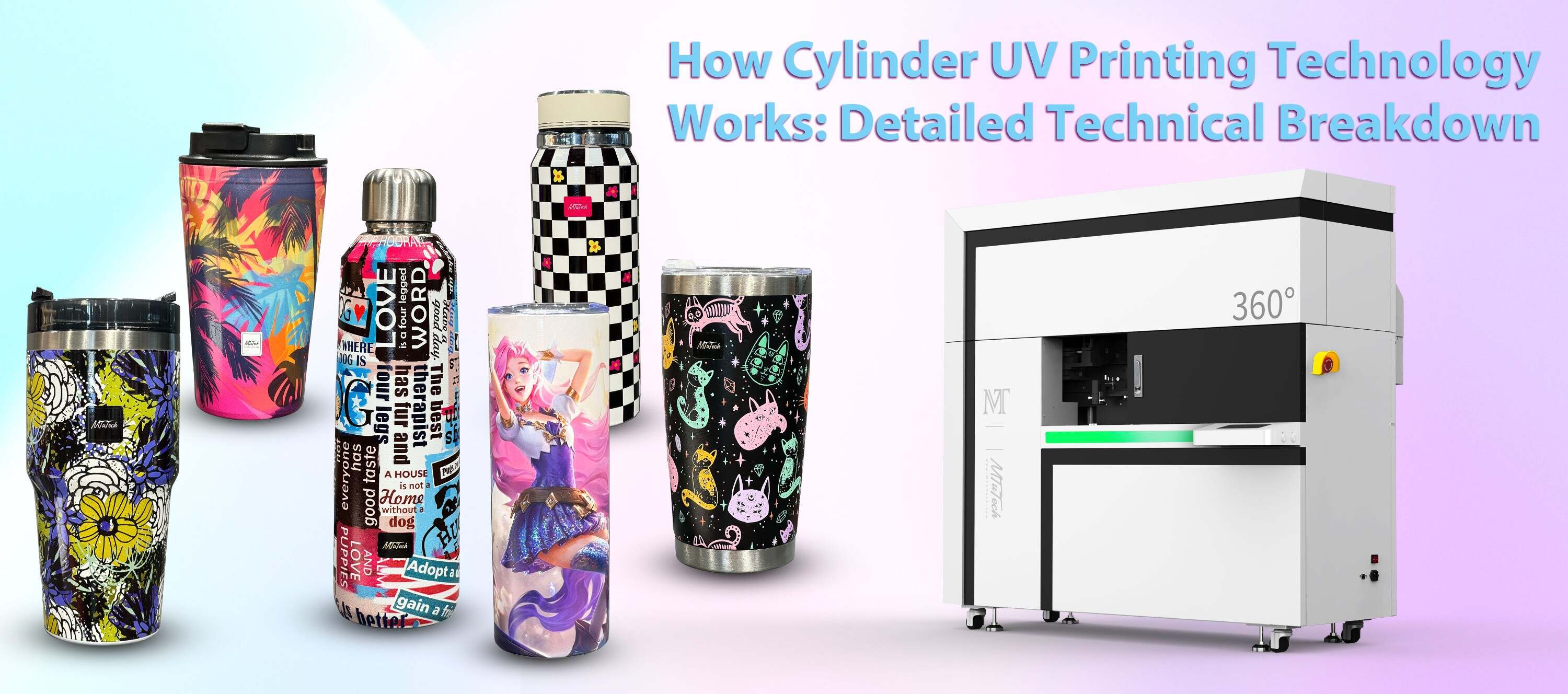

Cylindrical printing has revolutionized the way products are branded and marketed. From beverage cans to cosmetic containers, cylindrical objects are ubiquitous in our daily lives. One of the most critical aspects of cylindrical printing is the ink formulations used, which have greatly evolved over the years. This blog explores the journey of ink formulations used in cylindrical printing, their benefits, features, and future directions.

The History of Ink Formulations in Cylindrical Printing

The history of ink formulations can be traced back to the early days of printing. Originally, inks were made from natural dyes and pigments mixed with various binders, oils, and solvents. As printing technology advanced, particularly with the introduction of cylindrical printing methods, the demand for high-performance inks surged.

Early Ink Formulations

·

Naturally Derived Inks: The earliest inks were made from plant and mineral resources. These natural inks had limitations such as low durability and color fastness.

·

·

Oil-Based Inks: The 19th century saw the emergence of oil-based inks, which improved adhesion and drying times on smooth surfaces. However, these inks contained harmful solvents that posed health risks and environmental concerns.

·

Modern Ink Formulations

The late 20th century marked a significant turning point with the innovation of modern ink formulations. Advances in chemistry led to the development of synthetic inks that offered greater reliability and performance.

·

Solvent-Based Inks: These inks are widely used in cylindrical printing today, particularly for their strong adhesion and vibrant colors.

·

·

Water-Based Inks: Known for being more eco-friendly, water-based inks have gained popularity in printing applications due to their low volatility and minimal environmental impact.

·

·

UV-Curable Inks: These inks have transformed the cylindrical printing landscape. They cure rapidly when exposed to ultraviolet light, allowing for exceptional adhesion and durability.

·

Benefits of Evolving Ink Formulations

The evolution of ink formulations has brought numerous benefits to the cylindrical printing industry. Below are some of the most significant advantages:

Enhanced Performance

Modern inks exhibit improved performance metrics, including:

·

Rapid drying times, which boost production efficiency.

·

·

Superior adhesion properties, ensuring inks adhere to various substrates effectively.

·

·

Vibrant color reproduction, enhancing the aesthetic appeal of printed products.

·

Environmental Considerations

With growing awareness of environmental issues, the shift towards eco-friendly ink formulations is a notable benefit:

·

Water-based inks contain fewer volatile organic compounds (VOCs), reducing air pollution.

·

·

UV-curable inks minimize hazardous waste, as they do not emit solvents into the atmosphere.

·

·

Biodegradable inks are being developed to further lessen the environmental impact.

·

Cost-Effectiveness

Advancements in ink formulation have also led to cost savings:

·

Higher efficiency reduces material waste and lowers production costs.

·

·

The durability of modern inks decreases expenses related to reprints or replacements.

·

·

Economical bulk purchasing options provide cost benefits to manufacturers.

·

Features of Modern Ink Formulations

Modern ink formulations come with various features that cater to the needs of the cylindrical printing industry:

Customization

Today's ink formulations can be customized to meet specific requirements, including:

·

Varied color palettes to suit brand identities.

·

·

Specific viscosity levels for different printing speeds and methods.

·

·

Special additives that enhance features like gloss or matte finishes.

·

Versatility

Modern inks are designed to work on a variety of substrates including:

·

Plastic

·

·

Metal

·

·

Glass

·

·

Wood

·

This versatility allows businesses to expand their product offerings while maintaining print quality.

Durability

Durability is crucial in cylindrical printing, particularly for products exposed to the elements or frequent handling:

·

Water resistance prevents smudging and fading in wet conditions.

·

·

UV resistance protects colors from sun damage.

·

·

Scratch resistance ensures long-lasting prints.

·

The Future of Ink Formulations in Cylindrical Printing

The future of ink formulations in cylindrical printing is exciting, characterized by trends driven by technology and sustainability:

Sustainable Innovations

As eco-consciousness continues to rise, we can expect further innovations in sustainable ink formulations:

·

Development of inks from renewable resources.

·

·

Increased use of recycled materials in ink production.

·

·

Improvements in biodegradable inks that maintain performance without harming the environment.

·

Smart Inks

The integration of technology in ink formulations is paving the way for "smart inks":

·

Inks that change color with temperature or UV light.

·

·

Inks embedded with RFID chips for tracking and anti-counterfeiting purposes.

·

·

Interactive inks that respond to touch or heat, enhancing consumer engagement.

·

Automation and Digital Printing

With the rise of digital printing technologies, ink formulations will need to adapt:

·

Inks formulated for digital printing processes including inkjet and laser printers.

·

·

Focus on optimizing inks for faster production speeds without compromising quality.

·

·

Enhanced collaboration between ink manufacturers and printing equipment developers for seamless integration.

·

Conclusion

The evolution of ink formulations in cylindrical printing reflects the ongoing advancements in technology, chemistry, and environmental awareness. This transformation has led to improved performance, sustainability, and cost-effectiveness in printing processes. As the industry continues to innovate, we are likely to see even more groundbreaking developments that enhance the capabilities and applications of cylindrical printing.

For businesses seeking high-quality cylindrical printing solutions, explore our high-quality Cylindrical printers here. These printers utilize the latest innovations in ink formulations to ensure superior output and efficiency.

FAQ

What types of inks are best for cylindrical printing?

Solvent-based, water-based, and UV-curable inks are among the best choices for cylindrical printing, each offering unique advantages depending on application needs.

How have ink formulations improved over time?

Ink formulations have evolved to provide better adhesion, faster drying times, vibrant colors, and enhanced durability while also addressing environmental concerns.

Are eco-friendly inks effective in cylindrical printing?

Yes, eco-friendly inks like water-based and UV-curable inks offer effective performance while significantly reducing the environmental impact compared to traditional oil-based inks.

What is the future of ink formulations in cylindrical printing?

The future promises innovations such as sustainable inks made from renewable resources, smart inks with interactive capabilities, and further advancements in digital printing technologies.