The Impact of Cylinder UV Printing on Small Batch Manufacturing

Introduction

In the ever-evolving landscape of manufacturing, small businesses are constantly seeking innovative ways to stand out and enhance their production capabilities. One of the most transformative technologies in this regard is Cylinder UV Printing. This process not only elevates aesthetic appeal but also enhances efficiency and sustainability, making it an ideal choice for small batch manufacturing. This blog post explores the significant impact of Cylinder UV printing on this sector, focusing on its benefits, features, and why it's a game-changer for small manufacturers.

What is Cylinder UV Printing?

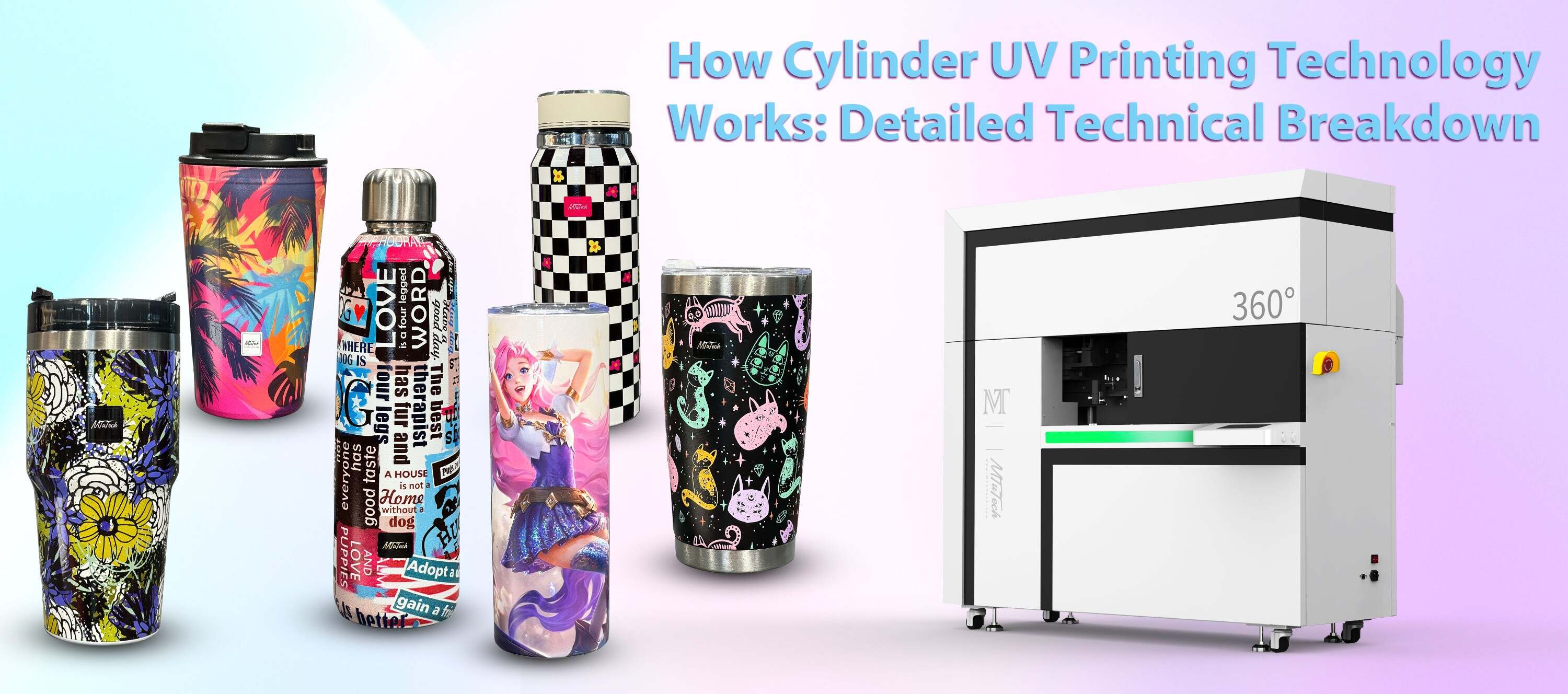

Cylinder UV printing is a specialized digital printing method that utilizes ultraviolet (UV) light to cure and dry the ink as it is printed onto a variety of cylindrical substrates. This process is particularly advantageous for products that require vibrant colors, intricate designs, and high durability. It is widely used for items such as bottles, cans, and promotional materials.

Benefits of Cylinder UV Printing for Small Batch Manufacturing

Increased Production Efficiency

One of the most notable benefits of Cylinder UV printing is the significant increase in production efficiency. Unlike traditional printing methods that may involve lengthy setups and drying times, Cylinder UV printing streamlines the process:

·

No need for plates or extensive pre-press setups

·

·

Instant drying and curing allow for immediate handling

·

·

Short run lengths are manageable without compromising speed

·

Enhanced Customization Options

With the slow decline of mass production, consumers now expect more personalized products. Cylinder UV printing allows manufacturers to provide unique, customized designs on a small batch scale:

·

Ability to print high-resolution images and graphics

·

·

Flexibility in creating limited edition products

·

·

Fast turnaround for tailored orders, meeting customer needs efficiently

·

Sustainability and Eco-Friendliness

As sustainability becomes a pressing concern for both consumers and manufacturers, Cylinder UV printing offers an eco-friendly solution. The process reduces waste and promotes environmentally conscious practices:

·

Minimal ink wastage due to precise printing technology

·

·

Low levels of volatile organic compounds (VOCs) compared to traditional methods

·

·

Ability to use recyclable substrates

·

Cost-Efficiency for Small Batches

While initial investments in printing equipment can be substantial, Cylinder UV printing ultimately proves cost-effective for small batch production:

·

No need for large inventory due to on-demand printing capabilities

·

·

Reduced labor costs associated with traditional printing setups

·

·

Lower costs incurred on materials and setup for short runs

·

Key Features of Cylinder UV Printing

Technology-Driven Precision

Cylinder UV printers offer advanced technology that ensures high-quality print outputs. Features such as variable ink density and precise color matching enable manufacturers to achieve the desired aesthetic without compromise.

Versatility in Material Handling

One of the most significant advantages of Cylinder UV printing is its versatility in handling various materials:

·

Compatible with different substrates, including glass, plastics, and metals

·

·

Prints directly on curved surfaces, eliminating the need for additional labeling

·

·

Allows for different ink types suitable for diverse product requirements

·

Durability and Resistance

The UV-cured inks used in Cylinder UV printing result in prints that are both vibrant and long-lasting. This durability comes with various resistance features:

·

Water and scratch resistance, enhancing the product lifespan

·

·

Fade resistance, maintaining visual appeal over time

·

·

Chemical resistance for products used in harsh environments

·

Adoption Challenges

While the benefits are compelling, small manufacturers may face challenges in adopting Cylinder UV printing. These challenges can include:

·

Initial investment costs for high-quality printers and setups

·

·

Learning curve for staff to master new technology

·

·

Maintenance and operational costs in keeping the equipment running efficiently

·

Conclusion

Cylinder UV printing represents a significant evolution in the manufacturing landscape, particularly for small batch producers. The advantages it offers—ranging from enhanced customization and operational efficiency to eco-friendly practices—position it as a compelling choice for businesses looking to elevate their production capabilities. As technology continues to advance and more manufacturers explore these innovative printing options, Cylinder UV printing will undoubtedly secure its place at the forefront of modern manufacturing trends.

For those considering investing in this transformative printing technology, explore our high-quality Cylinder UV printers here and discover how they can revolutionize your small batch manufacturing process.

FAQ

What types of products can be printed using Cylinder UV printing?

Cylinder UV printing can be used to print on a variety of cylindrical objects, including bottles, cans, jars, and promotional items, allowing for a wide range of applications across different industries.

Is Cylinder UV printing environmentally friendly?

Yes, Cylinder UV printing is considered environmentally friendly due to its minimal ink wastage and low levels of volatile organic compounds (VOCs). This makes it a sustainable choice for manufacturers looking to reduce their environmental footprint.

How does Cylinder UV printing compare to traditional printing methods?

Compared to traditional printing methods, Cylinder UV printing is faster, allows for greater customization, produces more vibrant colors, and reduces drying times, which makes it ideal for small batch production.

What is the cost of investing in a Cylinder UV printer?

The cost of a Cylinder UV printer can vary significantly based on features and capabilities, but it is essential to consider that the long-term savings from reduced material waste and faster output often offset the initial investment.

What maintenance is required for Cylinder UV printers?

Regular maintenance for Cylinder UV printers typically includes cleaning print heads, checking for ink quality, and ensuring that the UV curing system is functioning properly to maintain print quality and equipment longevity.