The Role of Fixtures and Rotary Attachments in Cylinder UV Printing

Introduction

When it comes to printing on cylindrical objects, precision is everything. That's where fixtures and rotary attachments step in. These unsung heroes of the cylinder UV printing process ensure smooth, accurate rotation, proper alignment, and consistent image quality. In this blog, we’ll explore how the right fixtures and attachments make a big difference in performance, print quality, and efficiency.

What Are Fixtures and Rotary Attachments?

Fixtures and rotary attachments are mechanical components used to hold cylindrical objects in place and rotate them evenly during the printing process. These tools help the printer maintain alignment, reduce vibration, and allow seamless printing around curved surfaces.

Why They Matter in Cylinder UV Printing

- Ensure steady and uniform rotation

- Prevent misalignment and ghosting

- Adapt to different product sizes and shapes

- Improve efficiency and reduce misprints

Types of Fixtures and Attachments

- Adjustable rotary jigs for various diameters

- Chuck-style fixtures for narrow bottles or pens

- Rollers or belt-driven attachments for heavier or longer items

- Custom 3D-printed holders for unique product shapes

How to Choose the Right Fixture

- Match the fixture to your product’s size and shape

- Ensure grip strength without damaging the product

- Look for adjustable clamps to handle a variety of items

- Prioritize compatibility with your specific printer model

Tips for Using Fixtures Effectively

- Always clean contact surfaces before loading

- Check alignment before each print to avoid skewing

- Tighten but don’t over-tighten grips to prevent surface damage

- Use test prints to ensure the object stays in place during full rotation

Common Problems and Solutions

- Slippage: Use rubber-padded fixtures or increase grip tension

- Wobble: Ensure the item is centered and evenly weighted

- Misregistration: Recalibrate rotary settings or adjust start point in RIP software

Conclusion

Fixtures and rotary attachments are essential for taking full advantage of your cylinder UV printer. With the right tools, setup, and adjustments, you’ll achieve perfect alignment, repeatable results, and the confidence to print on virtually any cylindrical object — from slim pens to oversized bottles.

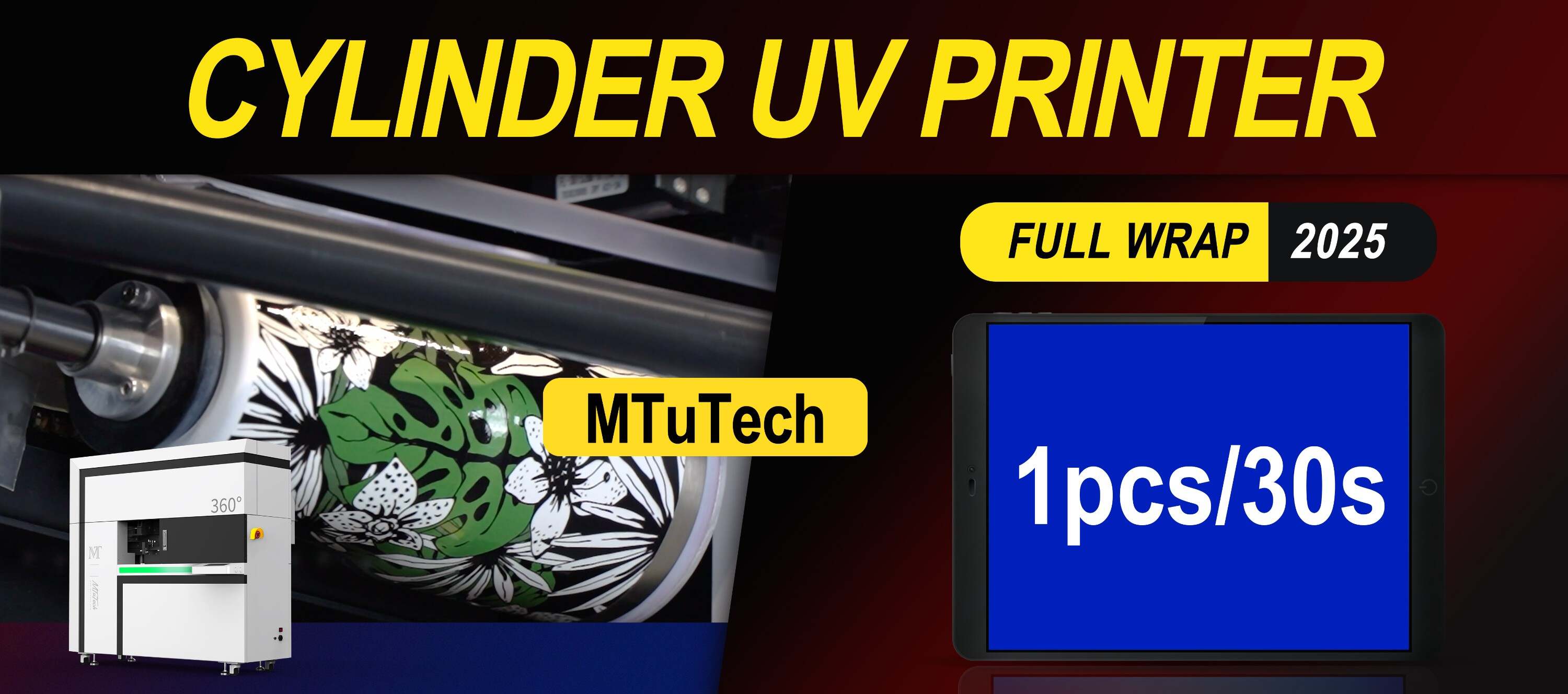

Learn how the right setup enhances results with our expertly designed cylinder UV printer — built with precision rotary attachments for seamless cylindrical printing.