Tumbler Printer Printhead Gap Settings for Different Material Thicknesses

Introduction

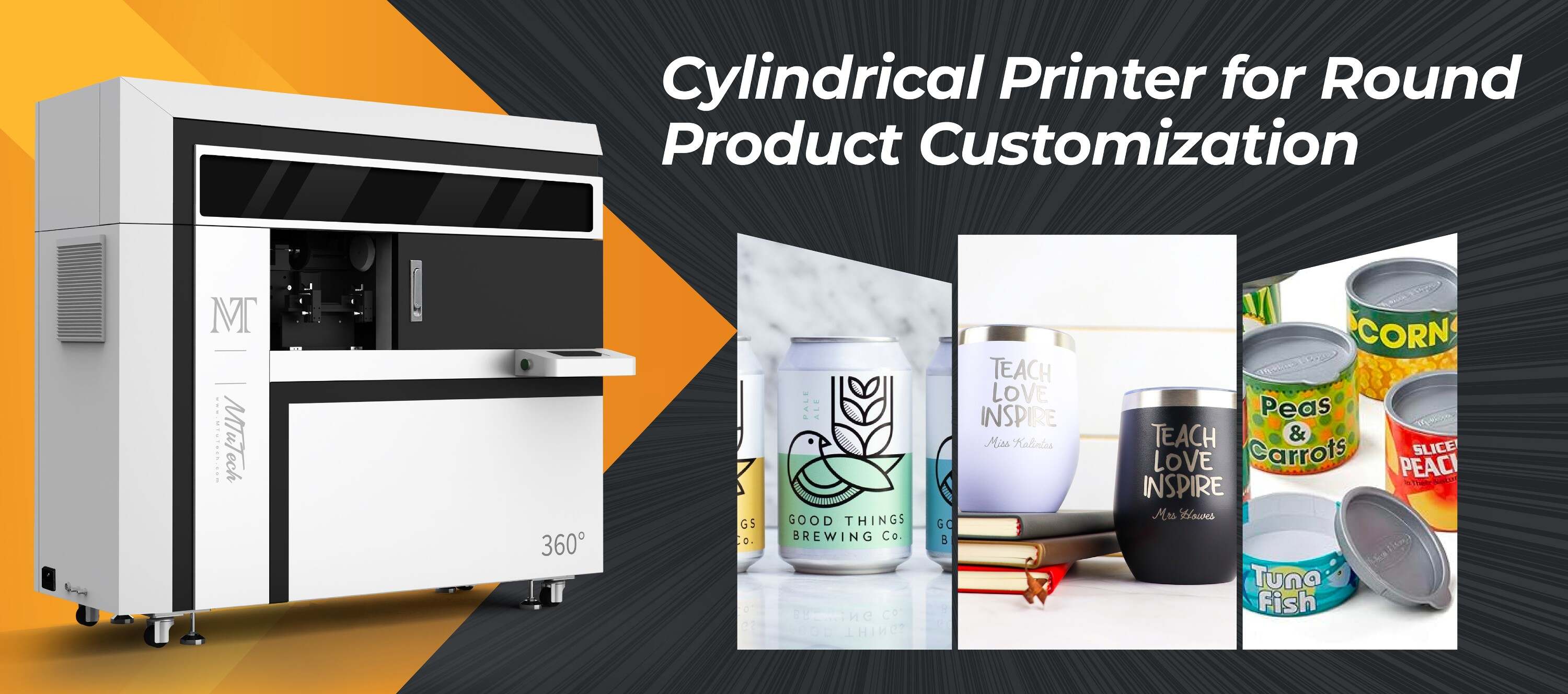

In the world of custom printing, tumbler printers have emerged as indispensable tools for achieving high-quality designs on drinkware. However, to ensure optimal print quality and adherence, understanding the printhead gap settings is crucial. This article will delve into how to adjust printhead gap settings based on different material thicknesses, enabling printer operators to achieve the best results with every print.

Understanding Printhead Gap Settings

The printhead gap refers to the distance between the printhead and the surface of the material being printed on. This gap is pivotal because it affects ink transfer, print quality, and overall production efficiency. Setting the right printhead gap for varying thicknesses of tumbler materials (such as stainless steel, plastic, or glass) ensures that the print is neither too light nor too heavy, reducing the chances of ink smudging or bleeding.

Why Printhead Gap Settings Matter

·

Print Quality: A correctly adjusted gap leads to crisp and vibrant designs, while an incorrect setting could result in blurry images or faded colors.

·

·

Material Preservation: Proper gap settings help prevent damage to the material and prolong the life of both the tumbler and the printer.

·

·

Ink Efficiency: Correct adjustments reduce ink wastage, ensuring a more cost-effective printing process.

·

Material Thickness and Printhead Gap Settings

The material thickness directly influences the appropriate printhead gap setting. Below are commonly used materials for tumbler printing and their recommended gap adjustments.

1. Stainless Steel Tumblers

Stainless steel is a popular choice for drinkware due to its durability and sleek appearance. For stainless steel tumblers, the recommended gap is typically in the range of 1.5 mm to 2 mm.

·

Thickness: Common thickness ranges from 0.4 mm to 0.8 mm.

·

·

Recommended Gap: Start at 1.8 mm and adjust to 2.0 mm for optimal ink adhesion.

·

2. Plastic Tumblers

Plastic tumblers, often lighter and more versatile, require different settings. The recommended printhead gap for plastic materials is generally between 1.2 mm and 1.5 mm.

·

Thickness: Plastic tumblers usually range from 0.3 mm to 0.6 mm.

·

·

Recommended Gap: A starting point of 1.3 mm is ideal, with adjustments made based on the type of plastic.

·

3. Glass Tumblers

Glass is often chosen for its aesthetic appeal. Printing on glass requires more precise adjustments due to its fragility. The recommended printhead gap settings for glass materials generally fall between 1.0 mm and 1.3 mm.

·

Thickness: Typical glass tumblers may have a thickness of 0.5 mm to 0.9 mm.

·

·

Recommended Gap: Begin with a 1.1 mm gap, ensuring higher precision to avoid breakage.

·

4. Ceramic Tumblers

Ceramic mugs and tumblers, known for their ability to hold vibrant prints, necessitate careful handling due to their brittle nature. Printhead gap settings for ceramic should be between 1.3 mm and 1.6 mm.

·

Thickness: Ceramic thickness ranges from 0.6 mm to 1.0 mm.

·

·

Recommended Gap: Start at 1.4 mm for optimal results, taking care to monitor ink flow closely.

·

Tips for Adjusting Printhead Gap Settings

Making precise adjustments to your tumbler printer's printhead gap can be achieved through the following tips:

·

Test Prints: Conduct test prints on each material type to evaluate the optimum gap settings.

·

·

Regular Calibration: Ensure your printer undergoes regular calibration for consistent print quality.

·

·

Monitor Ink Flow: Observe the ink flow during the initial prints to confirm the right gap has been set.

·

·

Use Quality Materials: The quality of your tumblers can also affect print quality; always choose high-quality materials for the best results.

·

Troubleshooting Common Printhead Gap Issues

Printhead gap issues can arise from improper settings, leading to various quality problems. Here are some common issues and their solutions:

1. Ink Smudging

If prints appear smudged, it may indicate that the printhead gap is too low. Increase the gap in 0.1 mm increments and retest.

2. Faded Prints

Faded or washed-out prints often suggest that the gap is too wide. Reduce the gap setting gradually until satisfactory quality is achieved.

3. Uneven Ink Distribution

Inconsistent ink application can be caused by fluctuating distances between the printhead and substrate. Ensure that gap settings are uniform throughout production runs.

Conclusion

Setting the correct printhead gap for your tumbler printer according to the material thickness is essential for achieving high-quality prints. Whether working with stainless steel, plastic, glass, or ceramic, understanding the nuances of each material's requirements will significantly enhance your printing outcomes. By following the guidelines and tips outlined above, you can ensure that your prints are not only visually striking but also durable and long-lasting. For those looking to invest in high-quality tumbler printers, explore our high-quality Tumbler printers here, which feature customizable settings to enhance your printing experience.

FAQ

What is the ideal printhead gap for tumbler printing?

The ideal printhead gap varies based on the material. Generally, stainless steel requires about 1.5 mm to 2 mm, while plastic can be set at 1.2 mm to 1.5 mm. Glass and ceramic typically need gaps of approximately 1.0 mm to 1.3 mm and 1.3 mm to 1.6 mm respectively.

How do I know if my printhead gap is set correctly?

Correctly set printhead gaps can be evaluated through test prints. Look for clear, vibrant images without smudging or fading, and adjust as necessary based on the results.

Can different brands of tumblers affect print quality?

Yes, different brands may use varying materials and finishes, impacting how well the print adheres. Always test accordingly and adjust the printhead gap based on specific brand attributes.