Tumbler Printing for Beginners – Tools, Setup & Results

Tumbler Printing for Beginners – Tools, Setup & Results

Introduction

Tumbler printing has gained immense popularity as a creative way to customize drinkware for personal use or as a business venture. Whether you're an avid DIY enthusiast, a small business owner, or someone looking to add a personal touch to gifts, understanding how to print on tumblers can be a rewarding skill. This guide will walk you through the essential tools, setup procedures, and expected results to get you started with tumbler printing.

What is Tumbler Printing?

Tumbler printing refers to the process of applying designs, texts, or images onto tumbler cups. Tumblers can be made of various materials, including stainless steel, plastic, and glass. With the right tools and techniques, you can create personalized drinkware suitable for promotions, events, or everyday use.

Essential Tools for Tumbler Printing

Before diving into the printing process, you need the right equipment. Here’s a list of tools that you’ll need:

·

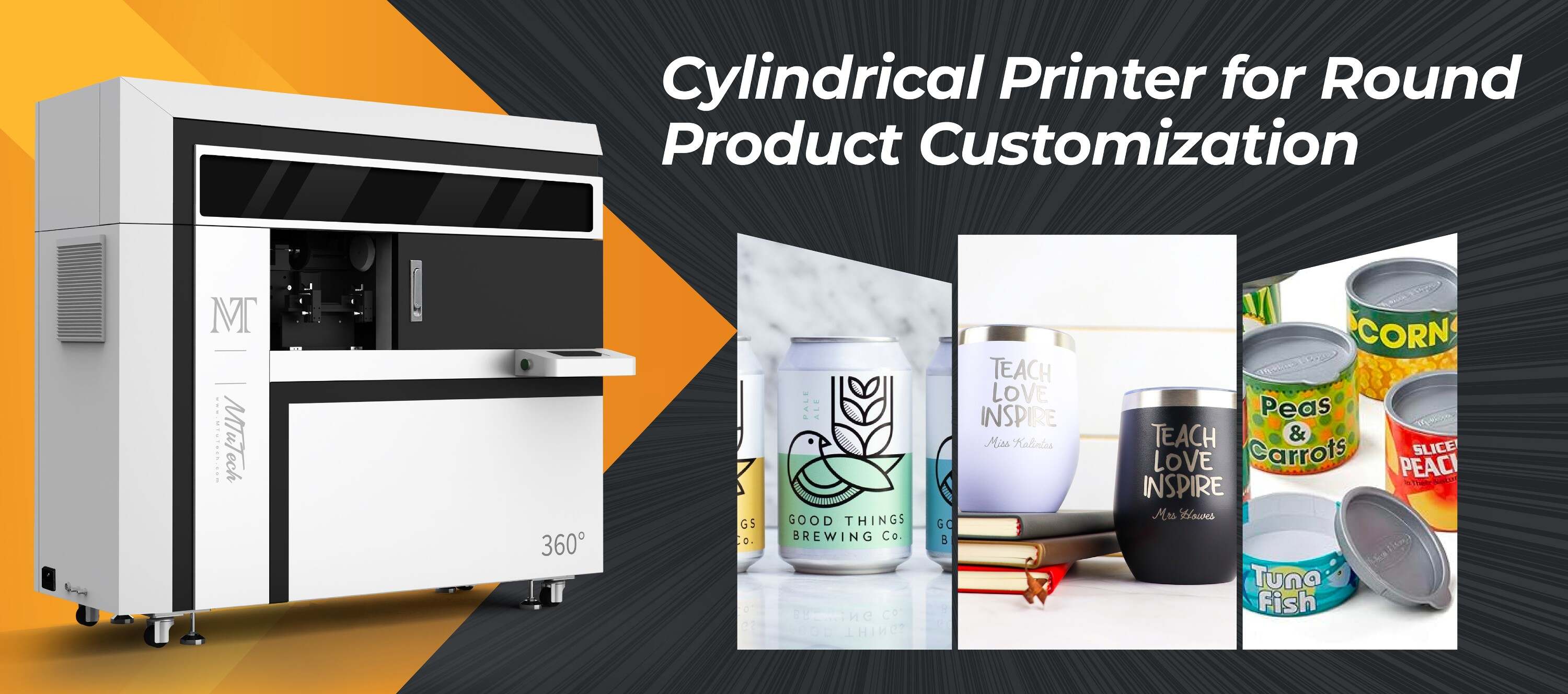

Tumbler Printer: A high-quality tumbler printer is key to achieving professional results. These printers are designed specifically for printing on curved surfaces.

·

·

Heat Press Machine: This tool is often used for applying heat to transfer designs onto the tumbler.

·

·

Transfer Paper: Use sublimation transfer paper or vinyl transfer sheets depending on the printing method.

·

·

Design Software: Software like Adobe Illustrator, CorelDRAW, or simpler options like Canva help you design your custom graphics.

·

·

Protective Gloves: To handle hot tumblers and protect your hands during the printing process.

·

·

Cleaning Supplies: Ensure your tumblers are clean and free of debris before printing. Use isopropyl alcohol for glass and stainless steel.

·

Setting Up Your Tumbler Printing Workspace

Creating a conducive workspace can significantly enhance your tumbler printing experience. Consider the following setups:

1. Choose a Suitable Location

Select a well-ventilated area to avoid inhaling fumes, especially when using heat press machines and inks. A dedicated table or workspace will help keep your tools organized.

2. Organize Your Tools

Keep all your printing supplies and tools within reach. Have your printer, heat press, and design software ready to minimize downtime.

3. Safety First

Always wear the appropriate protective gear, such as gloves and heat-resistant clothing, when using hot tools. Follow the safety guidelines provided by the device manufacturers.

Steps to Print on Tumblers

Now that you have your tools and workspace ready, follow these steps to start printing on tumblers:

Step 1: Design Your Graphic

Using design software, create or import the images you wish to print on the tumbler. Ensure the design fits the dimensions of your tumbler and adjust for any curves or ridges.

Step 2: Prepare the Tumbler

Before printing, clean the tumbler thoroughly with a suitable cleaner, ensuring it's free of dust and fingerprints. This will help the ink adhere better during the printing process.

Step 3: Print Your Design

If you're using sublimation printing, print your design onto sublimation transfer paper using your tumbler printer. Ensure that you use the correct ink and settings to achieve the best results.

Step 4: Heat Press the Tumblers

Place the transfer paper with your design onto the tumbler and secure it with heat-resistant tape to prevent shifting. Then, using your heat press machine, apply even pressure and heat according to the material specifications.

Step 5: Cool and Remove Transfer Paper

After the heat press cycle, allow the tumbler to cool down before carefully removing the transfer paper. This step reveals your customized design.

Step 6: Finishing Touches

Inspect your tumbler for any design flaws or imperfections. If necessary, clean up edges or add a clear coat for further protection.

Expected Results

The outcome of your tumbler printing project will depend on various factors, including your equipment quality, design complexity, and adherence to printing procedures. However, with practice, you can achieve:

·

Vibrant Colors: High-quality printers can produce stunning, vivid colors that pop.

·

·

Durability: A well-printed design will withstand washing and regular use without fading or peeling.

·

·

Professional Finish: Your tumblers can rival commercially produced items, making them perfect for personal use or resale.

·

Benefits of Tumbler Printing

Tumbler printing not only allows for personal expression but also offers numerous benefits:

·

Customization: Make unique gifts or products tailored to specific audiences, occasions, or preferences.

·

·

Low Start-up Costs: With relatively inexpensive tools, you can start your printing journey without a massive investment.

·

·

Market Demand: Customized drinkware is popular in online marketplaces, making it an excellent business opportunity.

·

·

Creative Outlet: Engage your creativity by designing custom graphics and experimenting with different styles.

·

Conclusion

Tumbler printing is an exciting venture that combines creativity, craftsmanship, and potential business opportunities. By investing in quality tools, setting up a proper workspace, and following the printing process, you can unlock the potential to create beautiful, customized tumblers. Whether for gifts, personal use, or a burgeoning business, tumbler printing offers endless possibilities. Ready to dive into the world of tumbler printing? Explore our high-quality Tumbler printers here and bring your creative visions to life!

FAQ

What materials can I print on?

You can print on various materials, including stainless steel, plastic, and glass. Each material may require different printing techniques and settings.

Can I use any printer for tumbler printing?

No, using a dedicated tumbler printer is essential to achieving the best results on curved surfaces. Standard printers may not produce satisfactory outcomes.

How do I ensure my designs last?

Properly applying heat and ensuring the tumblers are clean before printing are crucial. Additionally, consider using a clear coat for added protection.

Can I mass-produce tumblers?

Yes, once you have created your designs and perfected the process, you can mass-produce tumblers. However, ensure that you maintain quality control for each item.

How do I market my custom tumblers?

Utilize social media platforms, online marketplaces, and local craft fairs to showcase your products. Building a strong online presence can help attract more customers.