UV Printing Custom Barcodes and QR Codes on Cylindrical Items

Introduction

In today's fast-paced digital landscape, businesses are constantly seeking innovative ways to enhance product branding and facilitate easy accessibility for consumers. One such solution lies in the utilization of UV printing technology to create custom barcodes and QR codes on cylindrical items. This technique not only enhances the visual appeal of products but also provides essential information to consumers in a quick and efficient manner. As we delve deeper into the world of UV printing, we will explore its benefits, features, and practical applications in various industries.

What is UV Printing?

Ultraviolet (UV) printing represents a revolutionary approach to printing technology that utilizes UV light to cure or dry the ink as it is printed. This process offers a series of distinct advantages over traditional printing methods, particularly for cylindrical items, which can pose significant challenges for consistent ink application.

Benefits of UV Printing for Custom Barcodes and QR Codes

1. Versatile Material Compatibility

UV printing is compatible with a variety of materials, making it an excellent choice for cylindrical items made from plastic, glass, metal, and more. This versatility enables businesses to expand their product offerings while maintaining quality standards.

2. High-Quality Prints

The UV curing process results in sharper images and vibrant colors, ensuring that barcodes and QR codes are legible and visually appealing. This quality is essential for scannability and consumer interaction.

3. Durability

Prints created via UV technology are more durable than those produced through traditional methods. The cured ink is resistant to scratches, fading, and environmental factors such as moisture and UV light, ensuring longevity in various conditions.

4. Environmentally Friendly

Unlike traditional inks that may emit volatile organic compounds (VOCs), UV inks are generally more environmentally friendly, making them a preferred option for companies focused on sustainability.

5. Customization Options

The UV printing process allows for high levels of customization. Businesses can create unique designs and layouts that reflect their brand identity, accommodating features like logos, product information, and marketing messages alongside barcodes and QR codes.

Features of UV Printing for Cylindrical Items

1. Precision Alignment

UV printing technology is equipped with advanced alignment systems that ensure barcodes and QR codes are accurately positioned on cylindrical surfaces. This precision is crucial for maintaining the operational efficiency of scanning devices.

2. Multiple Print Passes

To enhance print quality further, UV printers can utilize multiple print passes. This feature is particularly beneficial for items with intricate designs or those requiring opaque prints on transparent materials.

3. Fast Curing Time

The instant curing process of UV printing allows for rapid production times. Businesses can produce large batches of products with QR codes and barcodes swiftly, enabling quick turnaround times and efficient supply chain management.

4. Enhanced Scanning Technology

With advancements in scanning technology, UV-printed barcodes and QR codes can be scanned from various angles and distances. This flexibility benefits businesses and consumers alike by providing easier access to information.

Applications of UV Printing on Cylindrical Items

1. Beverage Industry

The beverage industry is one of the largest adopters of UV printing for cylindrical items, such as bottles and cans. Custom QR codes can link consumers to nutritional information, promotions, or interactive marketing campaigns.

2. Cosmetics Packaging

Cosmetics companies utilize UV printing for products in cylindrical containers like lipsticks and lotions. By incorporating scannable barcodes, brands can provide transparency regarding ingredients and promote brand loyalty.

3. Automotive Parts

In the automotive sector, cylindrical components often require barcoding for inventory management. UV printing offers durable and reliable codes that can withstand harsh working conditions.

4. Pharmaceuticals

Regulatory guidelines for pharmaceuticals necessitate precise tracking of products. Custom barcodes printed via UV technology help ensure accurate inventory management and consumer safety.

5. Customized Gifts

Businesses looking to create personalized products can leverage UV printing for custom barcodes and QR codes on cylindrical gifts. This method can facilitate easy sharing of digital content, such as photos or videos, enhancing the customer experience.

Best Practices for Implementing UV Printing

1. Selecting the Right Printer

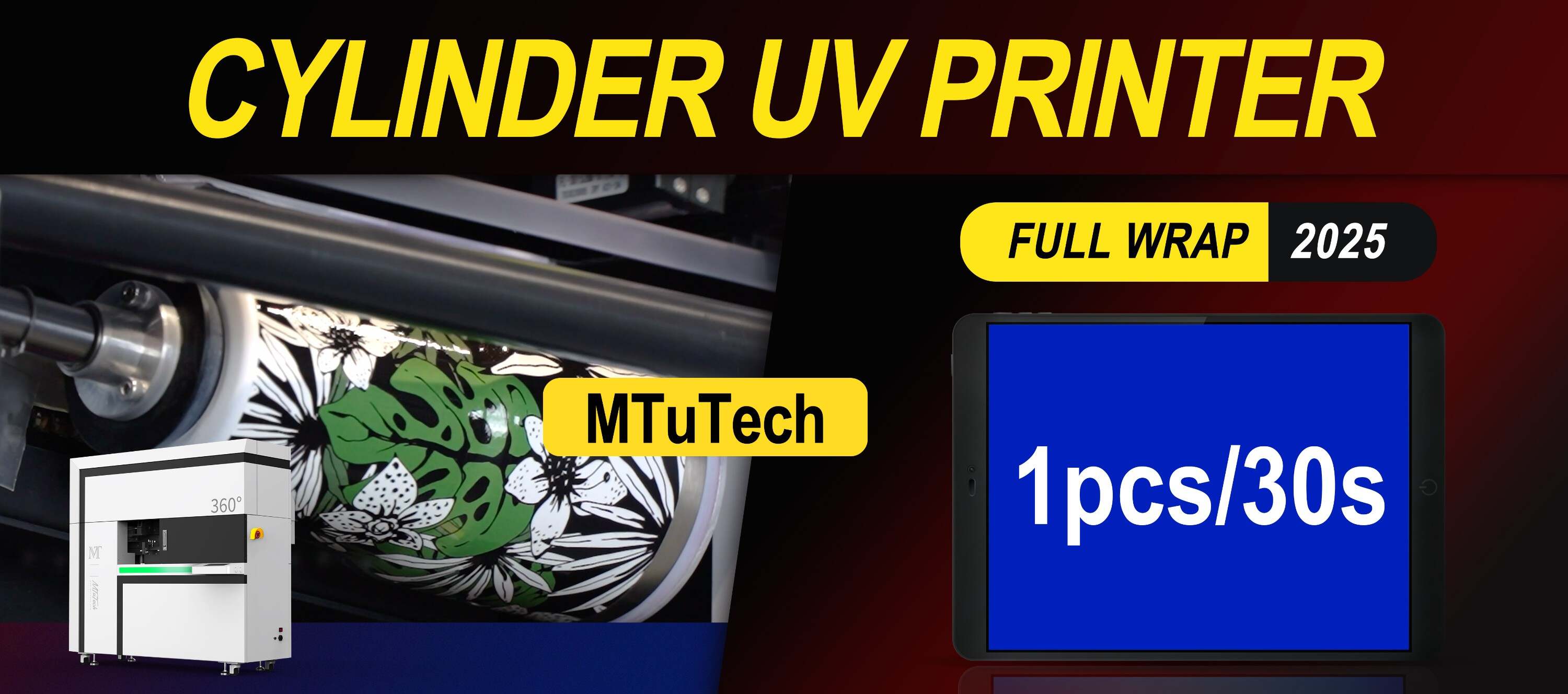

Choosing the right UV printer is essential for achieving desired results. Select models designed specifically to handle cylindrical objects to ensure optimal performance.

2. Designing for Scannability

Design barcodes and QR codes with scannability in mind. Avoid intricate graphics that can obstruct the code and ensure adequate contrast between the code and its background.

3. Testing Before Production

Conduct thorough testing of printed codes to ensure they function correctly before mass production. This step is crucial for maintaining customer satisfaction and operational efficiency.

4. Training Staff

Ensure that your staff is trained to use UV printing technology effectively. Proper knowledge and handling can prevent costly mistakes and lead to more efficient production processes.

Conclusion

UV printing for custom barcodes and QR codes on cylindrical items represents a significant advancement in product marking and branding. The technology not only improves the aesthetics and functionality of packaging but also enhances the overall consumer experience. By embracing UV printing, businesses across various industries can efficiently convey valuable information to consumers while maintaining a commitment to quality and sustainability. Overall, this innovative approach to printing is transforming how companies interact with their customers in a meaningful way. For more information on how UV printing can enhance your production capabilities, explore our high-quality Cylinder UV printers here.

FAQ

What types of cylindrical items can be printed using UV technology?

UV printing can be applied to a wide range of cylindrical items, including bottles, cans, tubes, and other packaging materials made from glass, plastic, or metal.

Are UV-printed barcodes and QR codes durable?

Yes, UV-printed barcodes and QR codes are highly durable. The curing process makes the ink resistant to fading, scratching, and moisture, ensuring they last throughout the product's lifetime.

How does UV printing benefit the beverage industry?

In the beverage industry, UV printing enhances branding and marketing efforts by allowing companies to print vibrant designs and interactive codes that engage consumers, provide nutritional information, and support promotional campaigns.

Can UV printing be environmentally friendly?

Yes, UV printing is often considered more environmentally friendly than traditional printing methods, as it generally produces fewer VOCs and waste materials, aligning with sustainability goals.

What should I consider when designing barcodes and QR codes?

When designing barcodes and QR codes, ensure they are clear, scannable, and not obstructed by design elements. Adequate contrast and size are also crucial to guarantee effective scanning.

UV Printing Custom Barcodes and QR Codes on Cylindrical Items

Introduction

In today's fast-paced digital landscape, businesses are constantly seeking innovative ways to enhance product branding and facilitate easy accessibility for consumers. One such solution lies in the utilization of UV printing technology to create custom barcodes and QR codes on cylindrical items. This technique not only enhances the visual appeal of products but also provides essential information to consumers in a quick and efficient manner. As we delve deeper into the world of UV printing, we will explore its benefits, features, and practical applications in various industries.

What is UV Printing?

Ultraviolet (UV) printing represents a revolutionary approach to printing technology that utilizes UV light to cure or dry the ink as it is printed. This process offers a series of distinct advantages over traditional printing methods, particularly for cylindrical items, which can pose significant challenges for consistent ink application.

Benefits of UV Printing for Custom Barcodes and QR Codes

1. Versatile Material Compatibility

UV printing is compatible with a variety of materials, making it an excellent choice for cylindrical items made from plastic, glass, metal, and more. This versatility enables businesses to expand their product offerings while maintaining quality standards.

2. High-Quality Prints

The UV curing process results in sharper images and vibrant colors, ensuring that barcodes and QR codes are legible and visually appealing. This quality is essential for scannability and consumer interaction.

3. Durability

Prints created via UV technology are more durable than those produced through traditional methods. The cured ink is resistant to scratches, fading, and environmental factors such as moisture and UV light, ensuring longevity in various conditions.

4. Environmentally Friendly

Unlike traditional inks that may emit volatile organic compounds (VOCs), UV inks are generally more environmentally friendly, making them a preferred option for companies focused on sustainability.

5. Customization Options

The UV printing process allows for high levels of customization. Businesses can create unique designs and layouts that reflect their brand identity, accommodating features like logos, product information, and marketing messages alongside barcodes and QR codes.

Features of UV Printing for Cylindrical Items

1. Precision Alignment

UV printing technology is equipped with advanced alignment systems that ensure barcodes and QR codes are accurately positioned on cylindrical surfaces. This precision is crucial for maintaining the operational efficiency of scanning devices.

2. Multiple Print Passes

To enhance print quality further, UV printers can utilize multiple print passes. This feature is particularly beneficial for items with intricate designs or those requiring opaque prints on transparent materials.

3. Fast Curing Time

The instant curing process of UV printing allows for rapid production times. Businesses can produce large batches of products with QR codes and barcodes swiftly, enabling quick turnaround times and efficient supply chain management.

4. Enhanced Scanning Technology

With advancements in scanning technology, UV-printed barcodes and QR codes can be scanned from various angles and distances. This flexibility benefits businesses and consumers alike by providing easier access to information.

Applications of UV Printing on Cylindrical Items

1. Beverage Industry

The beverage industry is one of the largest adopters of UV printing for cylindrical items, such as bottles and cans. Custom QR codes can link consumers to nutritional information, promotions, or interactive marketing campaigns.

2. Cosmetics Packaging

Cosmetics companies utilize UV printing for products in cylindrical containers like lipsticks and lotions. By incorporating scannable barcodes, brands can provide transparency regarding ingredients and promote brand loyalty.

3. Automotive Parts

In the automotive sector, cylindrical components often require barcoding for inventory management. UV printing offers durable and reliable codes that can withstand harsh working conditions.

4. Pharmaceuticals

Regulatory guidelines for pharmaceuticals necessitate precise tracking of products. Custom barcodes printed via UV technology help ensure accurate inventory management and consumer safety.

5. Customized Gifts

Businesses looking to create personalized products can leverage UV printing for custom barcodes and QR codes on cylindrical gifts. This method can facilitate easy sharing of digital content, such as photos or videos, enhancing the customer experience.

Best Practices for Implementing UV Printing

1. Selecting the Right Printer

Choosing the right UV printer is essential for achieving desired results. Select models designed specifically to handle cylindrical objects to ensure optimal performance.

2. Designing for Scannability

Design barcodes and QR codes with scannability in mind. Avoid intricate graphics that can obstruct the code and ensure adequate contrast between the code and its background.

3. Testing Before Production

Conduct thorough testing of printed codes to ensure they function correctly before mass production. This step is crucial for maintaining customer satisfaction and operational efficiency.

4. Training Staff

Ensure that your staff is trained to use UV printing technology effectively. Proper knowledge and handling can prevent costly mistakes and lead to more efficient production processes.

Conclusion

UV printing for custom barcodes and QR codes on cylindrical items represents a significant advancement in product marking and branding. The technology not only improves the aesthetics and functionality of packaging but also enhances the overall consumer experience. By embracing UV printing, businesses across various industries can efficiently convey valuable information to consumers while maintaining a commitment to quality and sustainability. Overall, this innovative approach to printing is transforming how companies interact with their customers in a meaningful way. For more information on how UV printing can enhance your production capabilities, explore our high-quality Cylinder UV printers here.

FAQ

What types of cylindrical items can be printed using UV technology?

UV printing can be applied to a wide range of cylindrical items, including bottles, cans, tubes, and other packaging materials made from glass, plastic, or metal.

Are UV-printed barcodes and QR codes durable?

Yes, UV-printed barcodes and QR codes are highly durable. The curing process makes the ink resistant to fading, scratching, and moisture, ensuring they last throughout the product's lifetime.

How does UV printing benefit the beverage industry?

In the beverage industry, UV printing enhances branding and marketing efforts by allowing companies to print vibrant designs and interactive codes that engage consumers, provide nutritional information, and support promotional campaigns.

Can UV printing be environmentally friendly?

Yes, UV printing is often considered more environmentally friendly than traditional printing methods, as it generally produces fewer VOCs and waste materials, aligning with sustainability goals.

What should I consider when designing barcodes and QR codes?

When designing barcodes and QR codes, ensure they are clear, scannable, and not obstructed by design elements. Adequate contrast and size are also crucial to guarantee effective scanning.