UV Printing Techniques for Double-Walled Cylindrical Items

UV Printing Techniques for Double-Walled Cylindrical Items

Introduction

In today’s dynamic printing industry, high-quality and innovative techniques have become essential for producing eye-catching products. One such technique that has gained significant popularity is UV printing, particularly for double-walled cylindrical items. This method not only enhances the aesthetic appeal but also ensures durability and versatility in various applications. This blog will delve into the specifics of UV printing techniques tailored for double-walled cylindrical items, exploring their benefits, features, and best practices for achieving outstanding results.

Understanding UV Printing

Ultraviolet (UV) printing is a modern printing process that uses UV light to cure or dry the ink as it is printed. This allows for immediate handling of printed materials, making it a favored choice for businesses that require quick turnaround times. The technology can print on a wide range of substrates, including double-walled cylindrical items like mugs, tumblers, and bottles.

What Are Double-Walled Cylindrical Items?

Double-walled cylindrical items are containers designed with two layers of material, providing insulation and durability. Common examples include:

·

Coffee mugs

·

·

Tumblers

·

·

Stainless steel bottles

·

·

Insulated drinkware

·

This structure not only maintains the temperature of beverages longer but also allows for varied printing techniques, ensuring that designs can withstand wear and tear while providing an attractive finish.

Benefits of UV Printing for Double-Walled Cylindrical Items

The advantages of using UV printing for double-walled cylindrical items are manifold:

·

Immediate Drying: UV printing uses ultraviolet light to dry the ink instantly, enabling faster production times and immediate use of printed items.

·

·

Vivid Colors: The curing process allows for brighter and more vibrant colors compared to traditional printing methods.

·

·

Durability: UV-cured inks are water- and scratch-resistant, making them ideal for everyday use conditions.

·

·

Eco-friendly Options: UV printing can produce minimal waste, is free of solvents, and offers less environmental impact compared to conventional printing techniques.

·

·

Versatility: UV printing can accommodate a variety of designs, sizes, and shapes, making it a flexible option for customization.

·

Features of UV Printing Techniques

The features of UV printing make it particularly suitable for double-walled cylindrical items:

1. High-Resolution Output

UV printers can achieve high-resolution images, essential for intricate designs and logos on cylindrical surfaces. This is crucial for brands looking to make a lasting impression.

2. Wide Color Gamut

The ability to use a wide range of colors means that businesses can closely match their branding and create unique designs that stand out.

3. Adaptability to Various Materials

Whether manufactured from stainless steel, plastic, or glass, UV printing adapts seamlessly to different materials, maintaining color fidelity and longevity.

4. Customization Capabilities

UV printing allows for extensive customization options, enabling businesses to cater to specific customer needs or promotional events, such as seasonal themes or corporate gifts.

5. Reduced Setup Times

The setup process for UV printing is generally quicker than traditional methods, allowing for last-minute changes and faster production cycles.

Best Practices for UV Printing on Double-Walled Cylindrical Items

To achieve the best results with UV printing on double-walled cylindrical items, consider the following best practices:

1. Surface Preparation

Ensure the surfaces of the cylindrical items are clean and free from oils or residues. A good surface ensures better ink adhesion and quality finishes.

2. Design Considerations

When creating designs, factor in the curvature of the cylindrical items. Text and images should be designed to wrap around seamlessly, avoiding distortion.

3. Printer Calibration

Regular calibration of UV printers helps maintain color accuracy and print quality. It’s essential to follow manufacturer guidelines for optimal performance.

4. Ink Selection

Select the right type of UV ink for your materials and intended use. Some inks are formulated specifically for certain surfaces, enhancing durability and adhesion.

5. Testing and Quality Control

Conduct test prints before full production runs. This helps identify any issues with design, ink adherence, or machine settings, ensuring high-quality output.

Conclusion

UV printing techniques offer unparalleled benefits for double-walled cylindrical items, making them an excellent choice for businesses looking to enhance their product offerings. With features like high-resolution output, vibrant colors, and adaptability to various materials, UV printing is the future of customized printing solutions. By adhering to best practices and utilizing quality equipment, brands can produce eye-catching and durable products that resonate with their customers.

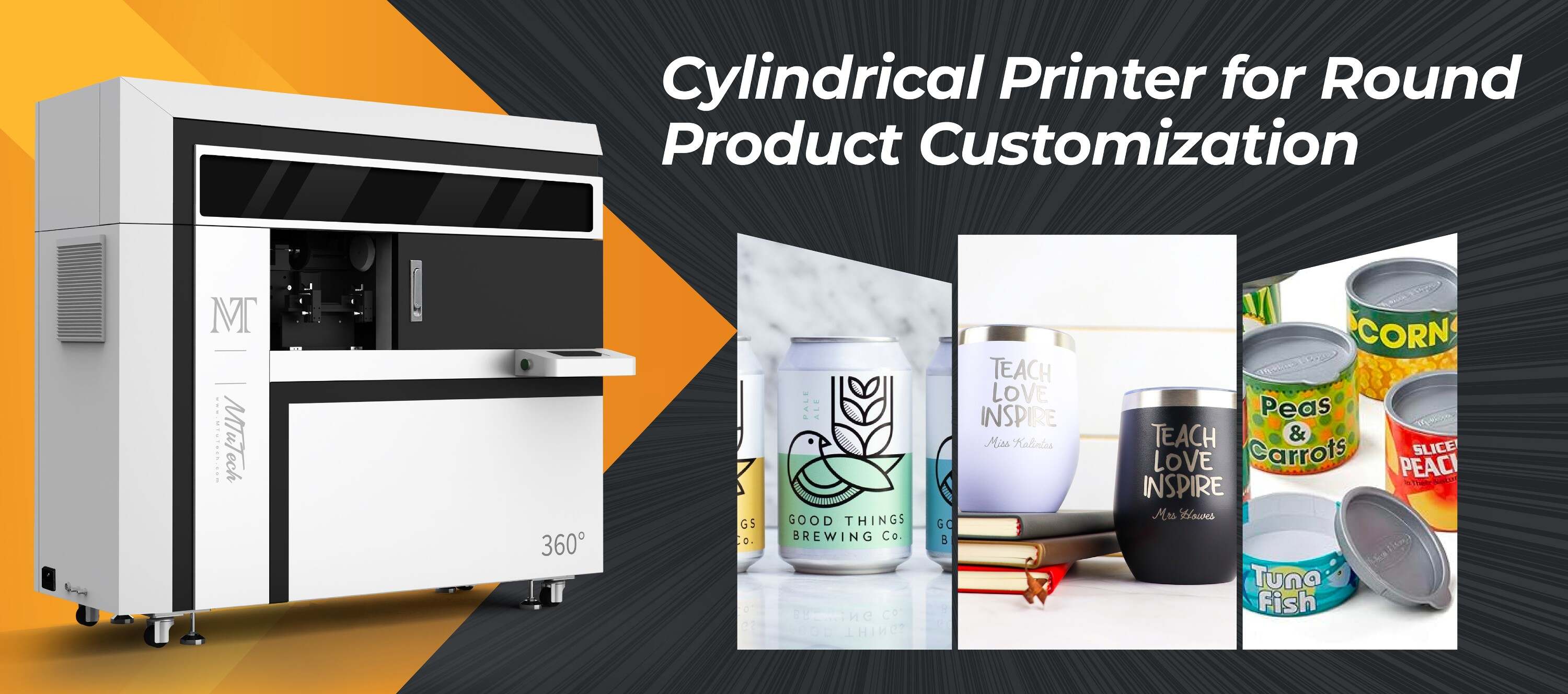

If you're interested in exploring cutting-edge technology to elevate your printing capabilities, explore our high-quality Cylinder UV printers here.

FAQ

What materials can be used with UV printing for double-walled cylindrical items?

UV printing can be used on various materials, including stainless steel, aluminum, glass, and some types of plastics. This versatility allows for a wide range of products to be customized effectively.

How durable are the prints produced by UV printing?

UV-cured prints are highly durable, resistant to water, UV rays, and scratches, making them suitable for everyday use on items like tumblers and mugs.

Is UV printing environmentally friendly?

Yes, UV printing is considered more environmentally friendly compared to traditional printing methods. It uses fewer volatile organic compounds (VOCs) and produces less waste during the printing process.

Can UV printing accommodate intricate designs?

Absolutely! UV printing is capable of producing high-resolution images, allowing for intricate designs, fine text, and detailed logos with ease.

What are the recommended maintenance practices for UV printers?

Regular maintenance should include routine cleaning of print heads, calibration, and ensuring that ink supplies are replenished. Following the manufacturer's guidelines is essential for achieving optimal performance.