UV Printing on Plastic Cylinders: Techniques and Considerations

Introduction

Plastic is one of the most common materials used in cylindrical products — from shampoo bottles and cosmetic tubes to drinkware and packaging containers. But UV printing on plastic cylinders requires special handling to ensure ink adhesion, durability, and visual clarity. This blog will walk you through the techniques and best practices for flawless UV printing on plastic surfaces.

Why Printing on Plastic is Challenging

- Many plastics have smooth, non-porous surfaces that resist ink bonding

- Oils or manufacturing residues can interfere with curing

- Different plastics (PP, PET, PVC, ABS) respond differently to UV inks

Preparing Plastic Cylinders for UV Printing

- Clean thoroughly with isopropyl alcohol to remove grease or dust

- Use adhesion promoters or flame treatment if ink adhesion is poor

- Handle items with gloves to avoid leaving fingerprints on prepped surfaces

Choosing the Right UV Inks

- Look for flexible UV inks designed for plastics and curved surfaces

- Some printers support dual-ink systems or offer special adhesion boosters

- Test compatibility with your specific plastic type before mass production

Adjusting Your Print Settings

- Use slower print speeds for better ink laydown

- Calibrate printhead height precisely to avoid contact and maintain quality

- Adjust UV lamp intensity and curing time for full adhesion without over-curing

Design Tips for Plastic Cylinders

- Avoid extremely fine details near edges where the surface curves more sharply

- Use bold colors with high contrast for better visibility on translucent plastics

- Include underbase white ink if printing on dark or colored plastics

Post-Print Handling

- Let the print cure completely before handling or packaging

- Avoid stacking freshly printed items too soon to prevent smudging

- Conduct adhesion tests (scratch, tape pull, water immersion) to verify durability

Conclusion

UV printing on plastic cylinders opens the door to high-quality customization across a wide range of industries. With proper surface prep, ink selection, and print settings, you can achieve vivid, durable prints that perform well and look fantastic on every product.

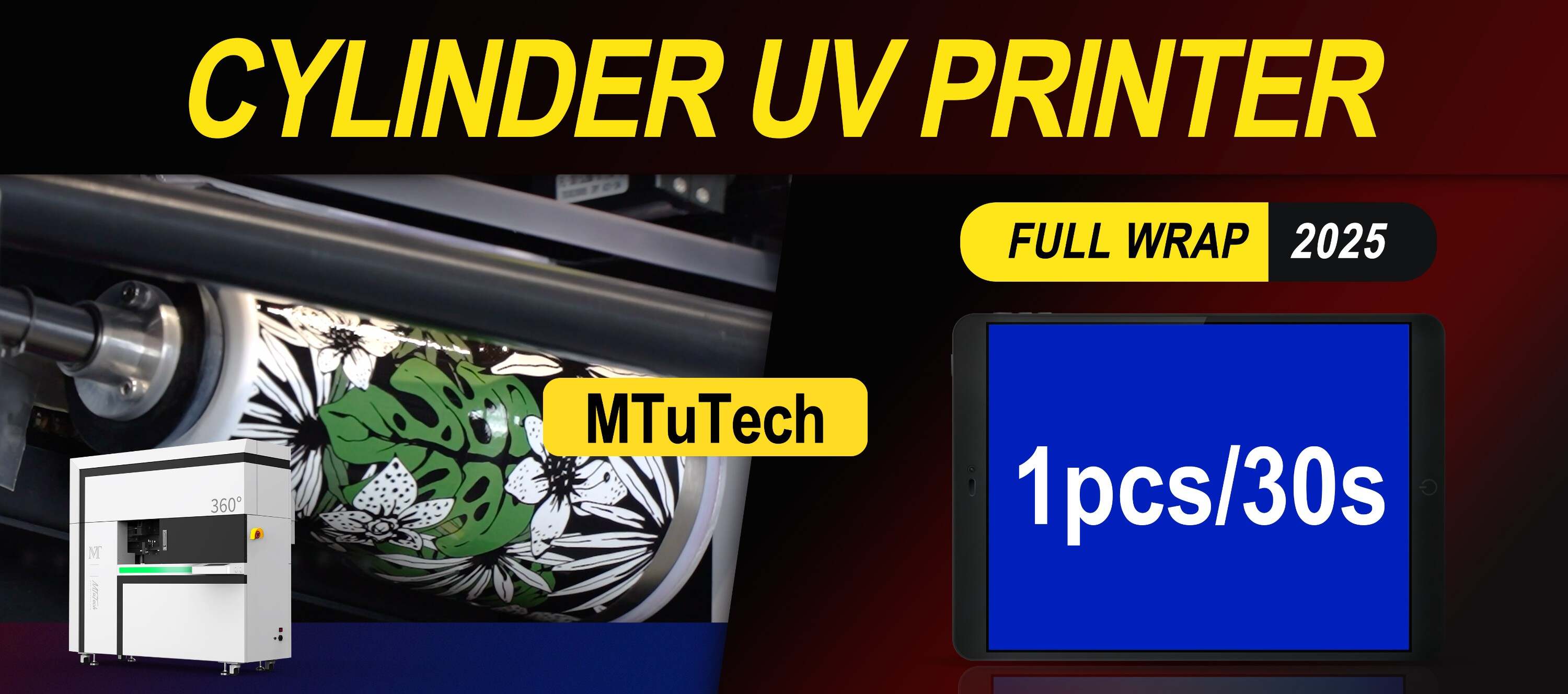

Ready to take on plastic customization with confidence? Discover the power of our cylinder UV printer — optimized for precise printing on all types of cylindrical plastic containers.