UV vs. Screen Cylindrical Printing – What’s Right for You?

Introduction

In the world of printing, particularly when it comes to cylindrical objects such as bottles, cans, and other tubular items, technology continues to evolve, offering various techniques tailored to different needs. Two prominent methods are UV (Ultraviolet) cylindrical printing and screen cylindrical printing. Understanding the differences between these two options is essential for selecting the most suitable method for your printing requirements. In this article, we’ll delve into the mechanics, benefits, and features of each technique, helping you decide what’s right for you.

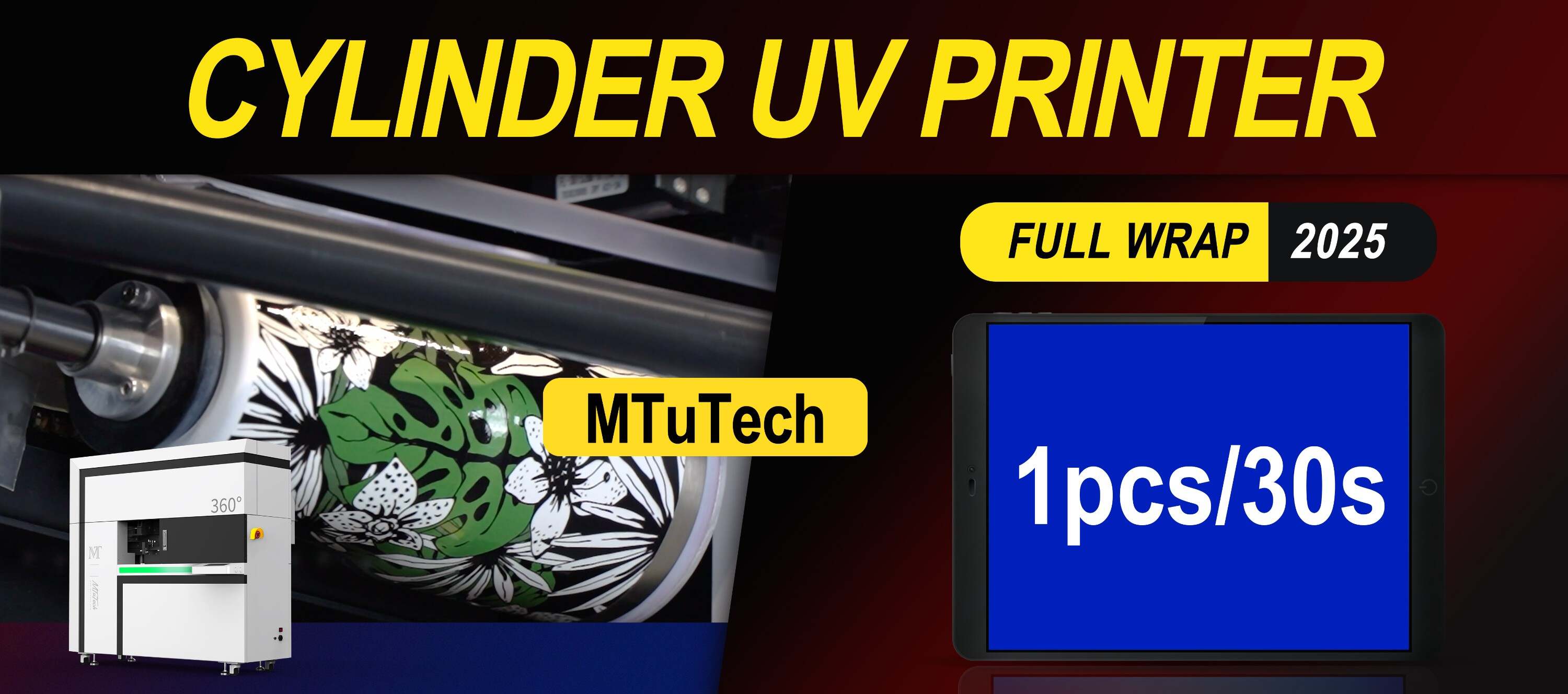

What is UV Cylindrical Printing?

UV cylindrical printing is a modern printing technique that utilizes ultraviolet light to cure ink as it is printed onto cylindrical surfaces. This method employs UV-sensitive inks that dry instantly upon exposure to UV light, allowing for vibrant and durable prints.

Mechanics of UV Printing

The process begins with the placement of the cylindrical object into the printer. Specialized print heads deposit the UV ink onto the surface. Once applied, the ink passes under a UV lamp which emits light that instantly hardens the ink. This process allows for high-resolution images and precise detailing on a variety of surfaces.

What is Screen Cylindrical Printing?

Screen cylindrical printing, or screen printing, is a more traditional method where ink is pushed through a stencil (or screen) onto the cylindrical surface. Screen printing is renowned for its ability to produce vibrant colors and is often used for bulk production runs.

Mechanics of Screen Printing

In screen cylindrical printing, a mesh screen, often made from silk or synthetic threads, is stretched tightly over a frame. The areas that will not print are blocked off, while the desired design is left open. Ink is then forced through the screen onto the substrate using a squeegee. The item is then often heat-treated to cure the ink.

Key Differences Between UV and Screen Cylindrical Printing

While both printing methods may serve the same purpose of decorating cylindrical objects, they differ significantly in several aspects:

1. Ink Curing Process

·

UV Printing: Cures instantly under UV light, leading to a quick finishing time.

·

·

Screen Printing: Requires a heat treatment phase for curing, which can lengthen production timelines.

·

2. Color Vibrancy and Detail

·

UV Printing: Known for its ability to produce high-resolution and vibrant colors. The instant curing allows for intricate designs.

·

·

Screen Printing: Applies a thicker layer of ink, which can result in bright colors, but may not achieve the same level of detail as UV printing.

·

3. Substrate Compatibility

·

UV Printing: Works effectively on a wide variety of surfaces, including glass, metal, and plastic.

·

·

Screen Printing: Also versatile but may demand specific inks for various substrates to avoid issues such as bleeding.

·

4. Production Volume

·

UV Printing: Ideal for short to medium production runs due to low setup costs and quick processing.

·

·

Screen Printing: More cost-effective for large production runs, as the setup can be more labor-intensive.

·

5. Environmental Impact

·

UV Printing: Often utilizes eco-friendly inks that emit fewer volatile organic compounds (VOCs).

·

·

Screen Printing: While it can also use eco-friendly inks, it traditionally involves solvents that may have a higher environmental impact.

·

Benefits of UV Cylindrical Printing

Below are some key benefits of choosing UV cylindrical printing:

·

Fast production times: The instant curing process reduces downtime, allowing for quicker project turnaround.

·

·

High-quality prints: UV printing delivers exceptional quality and precise detail, making it ideal for intricate designs.

·

·

Durability: UV-cured inks are resistant to scratching, fading, and chemical exposure, resulting in long-lasting prints.

·

·

Versatile application: Suitable for a variety of materials, enhancing its adaptability for different client needs.

·

Benefits of Screen Cylindrical Printing

Screen cylindrical printing also offers its own set of advantages:

·

Cost-effective for large quantities: Economies of scale make screen printing a cost-effective option for larger orders.

·

·

Rich color saturation: The thicker applications of ink deliver vibrant colors that stand out.

·

·

Time-tested method: With a long history in the printing industry, screen printing is trusted by many for consistent results.

·

·

Flexibility in ink types: Various inks (plastisol, water-based, etc.) can be used for specific effects and substrate compatibility.

·

Which Printing Method Should You Choose?

Choosing between UV and screen cylindrical printing depends on several factors, including your budget, production volume, design complexity, and required durability. Here are some considerations to help you make your decision:

Design Complexity

If your design is intricate and requires high detail, UV printing is the way to go. Its precision and ability to render fine lines and gradients can bring your vision to life. On the other hand, if your design is simpler or if you wish to achieve a certain tactile quality with thicker inks, screen printing could be the better choice.

Production Volume

Budget Considerations

While screen printing can be less expensive for large orders, the initial setup might be a deterrent for small batches. UV printing, though typically more costly per unit, offers high quality and speed, useful for projects that require quick delivery.

Conclusion

Ultimately, the choice between UV and screen cylindrical printing will depend on your specific needs, including design, budget, and volume. Both methods have their unique advantages, and understanding these can help you make an informed decision. For precise, vibrant, and quick printing solutions, UV cylindrical printing stands out. Conversely, if you are looking for cost-effective solutions for large volumes with bold color requirements, screen printing could be the option you need. Whatever your decision may be, ensure it aligns with your brand's vision and operational requirements.

For those looking for high-quality cylindrical printers to support your printing endeavors, explore our high-quality cylindrical printers here.

FAQ

What are the main advantages of UV printing over screen printing?

The main advantages of UV printing include faster production times, high-quality prints with precise detailing, and durability against scratches and fading. It's also versatile, working on various materials with eco-friendly ink options.

Can I use UV printing for all types of cylindrical objects?

Yes, UV printing is highly versatile and can be utilized on various materials, including glass, plastic, and metal. Just ensure that the substrate is compatible with UV inks.

Which printing method is more cost-effective for large runs?

Screen printing is generally more cost-effective for large production runs due to its economies of scale, reducing the cost per unit. However, UV printing can be more efficient for smaller batches due to quicker turnaround times.

How does the durability of prints differ between these methods?

UV-cured prints are known for their exceptional durability, resisting scratches, fading, and chemical exposure. Screen printed items can also be durable but may require specific inks and coatings to achieve similar longevity.

Is it possible to combine both printing methods?

Yes, in some cases, businesses may choose to combine both methods to leverage the strengths of each. For example, screen printing may be used for base colors, while UV printing could add elaborate details or effects.