Understanding UV Ink Adhesion on Coated Cylindrical Surfaces

Introduction

In today's dynamic printing landscape, the importance of UV ink adhesion on coated cylindrical surfaces cannot be overstated. As industries evolve and demand for high-quality printed products increases, understanding the science behind UV inks becomes vital for manufacturers and print service providers. This blog post delves into the intricacies of UV ink adhesion, emphasizing its significance, factors influencing adhesion, and tips for ensuring optimal results.

The Science of UV Ink

UV inks are specially formulated to dry quickly under ultraviolet light, which makes them an excellent choice for various printing applications, particularly on cylindrical surfaces. However, the success of UV printing largely relies on the adhesion of the ink to the substrate, which can be complex due to the unique properties of cylindrical coatings.

What is UV Ink Adhesion?

UV ink adhesion refers to the ability of UV inks to bond effectively to the coated surfaces of cylindrical substrates. Achieving good adhesion is critical to prevent issues like smudging, flaking, or peeling, which can compromise the quality and longevity of the print.

Importance of Adhesion

Proper adhesion is essential for several reasons:

·

Durability: Strong adhesion ensures that prints withstand environmental factors, including moisture, heat, and abrasion.

·

·

Color Fidelity: Well-adhered inks maintain their vibrancy and prevent fading over time.

·

·

Efficiency: Good adhesion reduces the likelihood of reprints, saving both time and resources.

·

·

Brand Image: High-quality prints boost brand reputation and customer satisfaction.

·

Factors Affecting UV Ink Adhesion

Understanding the variables that impact UV ink adhesion is crucial for achieving optimal printing results. Here are the major factors to consider:

Surface Energy

The surface energy of the material directly impacts the ink's ability to wet and spread across the substrate. High surface energy materials, like metals and some plastics, tend to promote better adhesion, while low surface energy materials, like certain coated surfaces, can lead to adhesion challenges.

Substrate Type

The type of substrate being used plays a significant role in adhesion quality. Coated cylindrical surfaces can vary widely in their properties, including smoothness, porosity, and chemical composition. Each substrate may require specific UV ink formulations or pre-treatment processes to achieve optimal adhesion.

Pre-treatment Processes

Implementing pre-treatment techniques can significantly enhance ink adhesion on coated surfaces. Common pre-treatment methods include:

·

Corona Treatment: Increases surface energy, promoting better ink adhesion.

·

·

Flame Treatment: Alters the surface structure, enhancing wetting characteristics.

·

·

Plasma Treatment: Improves receptivity of the substrate to inks.

·

Ink Composition

The choice of UV ink formulation is critical. Different inks have varying levels of viscosity, adhesion promoters, and curing agents. Selecting the right ink for the specific coated surface can lead to better adhesion and print quality.

Curing Process

The effectiveness of the curing process significantly affects ink adhesion. Proper UV curing ensures that the inks are fully polymerized, achieving optimal bonding with the substrate. Factors to consider include:

·

Curing Lamp Intensity: Adequate lamp intensity is crucial for thorough curing.

·

·

Speed of the Printing Process: Higher speeds may require adjustments to curing times to maintain adhesion quality.

·

·

Distance from the Lamp: The distance between the ink and the UV source can influence the degree of curing.

·

Testing Ink Adhesion

To ensure that UV inks adhere properly to coated cylindrical surfaces, testing is essential. Here are some common methods used for evaluating ink adhesion:

Adhesion Tape Test

This simple test involves applying adhesive tape to the printed surface and removing it quickly. A successful outcome will leave no ink residue on the tape.

Cross-Hatch Test

This involves creating a cross-hatch pattern on the printed sample and applying tape over it. The amount of ink that comes off indicates the level of adhesion, allowing for a quantitative assessment.

Scrape Test

A blade is used to scrape the surface, and the amount of ink removed provides insights into adhesion strength. This method is particularly useful for assessing adhesion in harsh environments.

Best Practices for Enhancing UV Ink Adhesion

To maximize UV ink adhesion on coated cylindrical surfaces, consider the following best practices:

Choose the Right Substrate

Select substrates that are compatible with UV inks. Consider factors such as surface finish, texture, and chemical compatibility when making your choice.

Optimize Pre-treatment Strategies

Implement the appropriate pre-treatment processes based on the substrate type to enhance surface energy and improve ink receptivity.

Utilize High-Quality UV Inks

Invest in high-performance UV ink formulations specifically designed for your substrates to ensure proper adhesion and durability.

Adjust Curing Parameters

Fine-tune the curing parameters according to the printer’s settings and the characteristics of the substrate to achieve the best results.

Regular Testing and Quality Control

Conduct regular tests on adhesion to catch any potential issues early on. Implementing a robust quality control process can help maintain high standards across production runs.

Conclusion

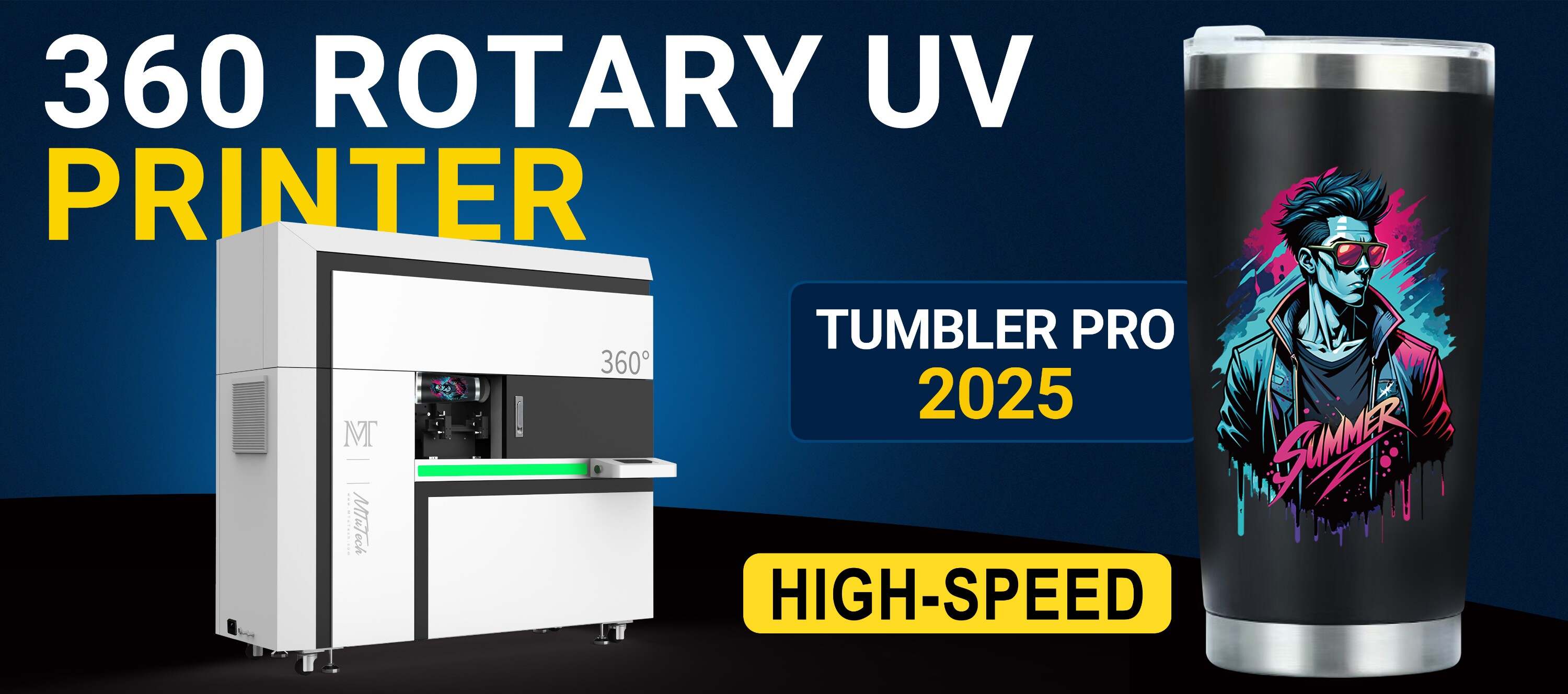

Understanding UV ink adhesion on coated cylindrical surfaces is pivotal for achieving quality printing results. Regardless of the complexities involved, by mastering the factors affecting adhesion and implementing best practices, print service providers can ensure high-quality outputs, enhance efficiency, and increase customer satisfaction. For those seeking to elevate their printing capabilities, consider exploring advanced technologies and solutions tailored to this specialty. Explore our high-quality Cylinder UV printers here and stay ahead in the competitive printing landscape.

FAQ

What are UV inks, and how do they work?

UV inks are specially formulated inks that cure quickly when exposed to ultraviolet light. They consist of pigments, monomers, and photoinitiators that react and polymerize upon UV exposure, creating a durable print surface.

Why is adhesion testing necessary in UV printing?

Adhesion testing is essential to ensure that prints will withstand environmental challenges and maintain their quality over time. It helps identify any potential adhesion issues before full-scale production.

Can all substrates be printed using UV inks?

No, not all substrates are suitable for UV printing. It is important to choose materials that have compatible properties with UV inks to ensure effective adhesion and avoid common printing issues.

What is the role of curing in UV printing?

The curing process in UV printing is crucial as it solidifies the ink, enabling it to bond effectively to the substrate. Proper curing can significantly impact adhesion quality and print durability.

How can surface preparation influence adhesion?

Effective surface preparation through techniques like corona or flame treatments can increase surface energy and enhance the ink's ability to bond with the substrate, leading to improved adhesion.