Client: EcoCarton Packaging, a forward-thinking corrugated box manufacturer in the Netherlands, supplying the food & beverage, e-commerce, and consumer goods sectors across Europe.

Challenge: EcoCarton's traditional flexographic printing process was cost-effective for large, static runs but completely inflexible for the growing market demand for short-run, highly customized, and just-in-time packaging. Clients, especially direct-to-consumer brands and seasonal food producers (e.g., artisanal pizza box producers, craft breweries, boutique cosmetics), needed boxes with vibrant, high-detail graphics, variable data (QR codes, unique batch codes), and versioning (seasonal designs, limited editions). Flexo made this prohibitively expensive due to high plate costs and lengthy setup times. They needed a solution to combine the quality of digital printing with the speed and scale of industrial production.

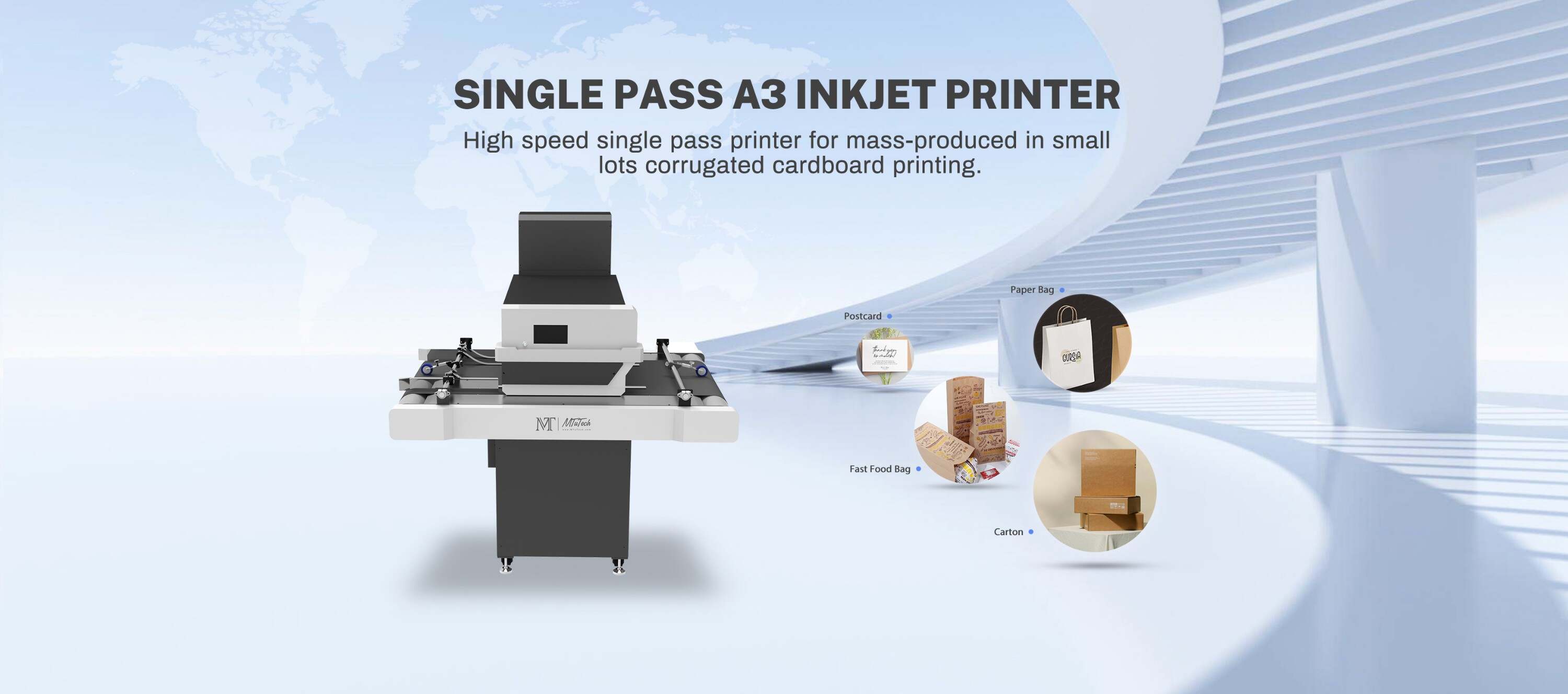

Solution: EcoCarton made a strategic investment in the “ MTuTech Single Pass Inkjet Production System", a dedicated digital press for corrugated materials. A complete single pass system consists of a feeding device and a printing device. This system features 3 different kinds of continuously automatic feeding devices, you can choose the suitable page-by-page feeder, vacuum feeder, or needle aspiration feeder based on the substrate type you need to print. So that they can feed amounts of corrugated materials quickly and accurately, boosts productivity greatly. Equips with Brother printhead, print width 305mm, print height 450mm. As the substrate passes continuously beneath the print bar at high speed, the entire image is deposited in a single, uninterrupted pass—eliminating the need for back-and-forth scanning.

Implementation & Process Details:

Integrated Pre-Press & Workflow: Customer orders, often containing hundreds of unique SKUs with slight design variations, are processed through a specialized workflow software. This software automatically rips the data, manages color profiles for brand-critical colors, and inserts variable content. The MTuTech single pass printer is integrated inline with a feeder and a high-precision conveyor belt system.

High-Speed, On-the-Fly Printing: Pre-cut, B- or E-flute corrugated sheets are fed into the system. The board moves under the stationary printheads at speeds exceeding 150 meters per minute. Piezoelectric printheads jet eco-friendly, water-based pigmented inks directly onto the often challenging, porous surface of the uncoated corrugated board. An instant drying/curing system follows immediately after the print bar.

Handling Complexity: The system excels at printing high-quality, photorealistic images for pizza boxes, detailed brand storytelling on wine shippers, and sharp scannable QR codes for e-commerce traceability on shipping boxes. It seamlessly switches from one unique design to the next with every sheet, with zero mechanical setup time or wasted material between jobs.

Post-Press: The printed sheets continue directly to a rotary die-cutter for conversion into finished boxes, bags, or trays, creating a near-seamless digital-to-finished-product workflow.

Results & Benefits:

Unmatched Agility: Reduced lead time for custom printed boxes from weeks to days (or even hours). They can now accept orders as low as 50-100 boxes profitably, opening up a massive new market segment.

Supply Chain Innovation: Enabled a "print-on-demand" model for major e-commerce clients, allowing regional warehouses to print boxes with localized marketing or language right before shipping, eliminating massive pre-printed inventory.

Sustainability & Waste Reduction: Digital production eliminated the need for printing plates, washes, and setup sheets, reducing chemical and material waste by over 60% for short runs. The just-in-time model also minimized obsolete, pre-printed box inventory.

Design Freedom: Clients can now use unlimited colors, intricate gradients, and high-resolution images without extra cost, dramatically enhancing shelf appeal for products like gourmet food gift boxes.

Quote from Client:

MTuTech single pass system didn't just add a new machine; it fundamentally changed our business proposition. We're no longer just a box supplier; we are a brand amplification partner. The ability to print a batch of 200 fully custom, photorealistic pizza boxes for a local chain's promotion, followed immediately by 500 unique e-commerce boxes for a fashion brand, all in one shift, is a capability that sets us apart. It has become the engine of our growth."*

– Lena van Dijk, Chief Operations Officer, EcoCarton Packaging