Introduction

In today's fast-paced world, custom printing solutions are essential for businesses seeking to make a lasting impression. Among the various printing technologies available, UV DTF (Direct to Film) printing has emerged as a standout method, offering versatility, durability, and vibrant color reproduction. This blog post will delve into the ins and outs of UV DTF custom printing, exploring its benefits, features, applications, and why it may be the perfect solution for your printing needs.

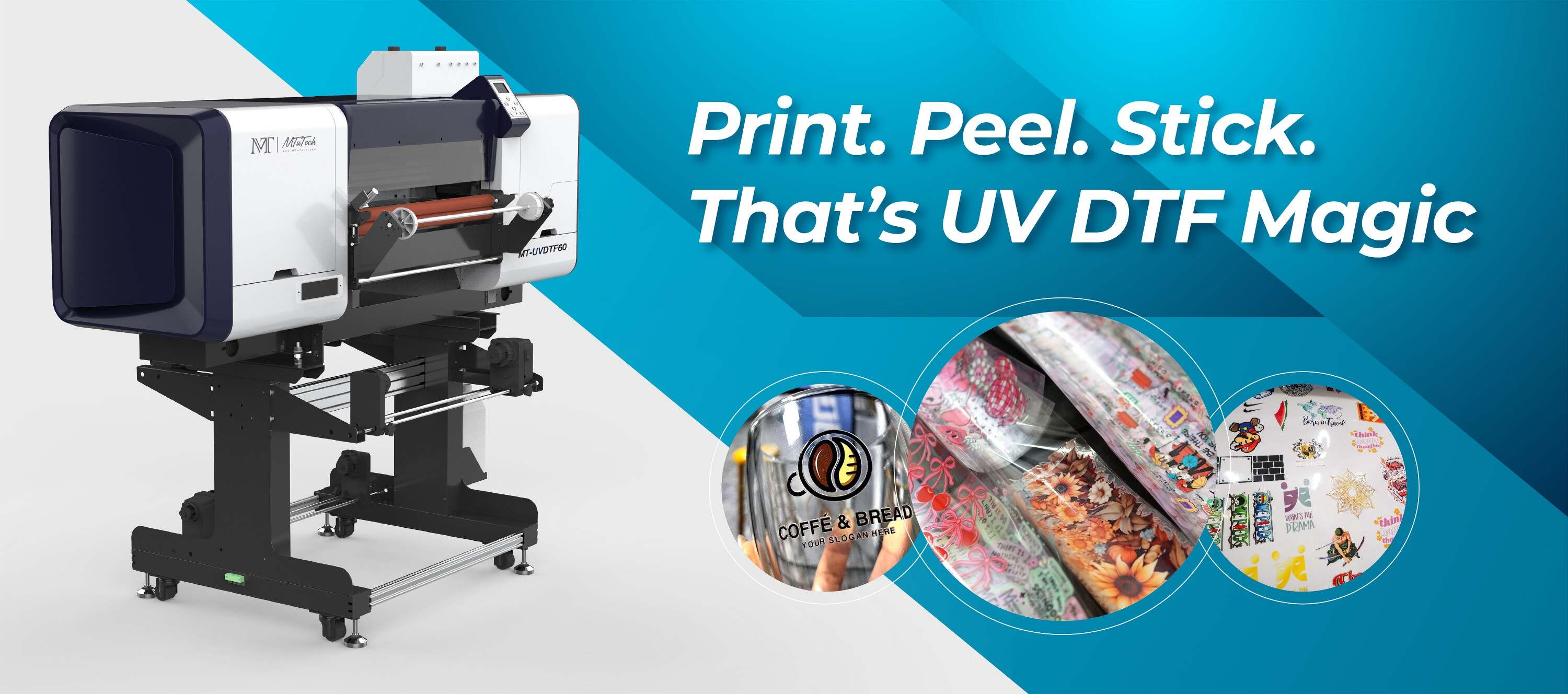

What Is UV DTF Printing?

UV DTF printing combines the advantages of UV printing and DTF technology. In this process, a specially formulated ink is printed onto a transparent film using UV-cured inks. This film is then transferred onto various substrates, including textiles, plastics, metals, and more. The UV curing process ensures that the inks are instantly dried, leading to high-quality prints that are vibrant and resistant to wear.

Benefits of UV DTF Custom Printing

1. High-Quality Prints

The primary advantage of UV DTF printing is the exceptional print quality it offers. The UV inks provide vivid colors and sharp details, making it ideal for intricate designs and artwork. The ability to use a wide range of colors ensures that your prints truly pop.

2. Versatility

UV DTF printing is suitable for a vast array of materials. Whether you need prints on fabric, wood, glass, or metal, UV DTF can handle it all. This versatility makes it an excellent option for businesses that require diverse printing capabilities.

3. Durability

The UV curing process hardens the ink, making it resistant to scratches, fading, and water. This durability is particularly beneficial for items that will be subjected to wear and tear, ensuring that your prints maintain their quality over time.

4. Eco-Friendly Option

UV inks contain fewer volatile organic compounds (VOCs) compared to traditional solvent-based inks, making UV DTF printing a more environmentally friendly option. This commitment to sustainability is increasingly important to consumers and businesses alike.

5. Short Production Time

Because the inks are cured instantly with UV light, UV DTF printing reduces production time significantly. This efficiency allows for faster turnaround times, making it a popular choice for businesses that need quick results.

Key Features of UV DTF Printing

1. Customization

One of the standout features of UV DTF printing is the ability to create highly customized products. Businesses can order prints tailored to their specific requirements, from unique designs to variable data printing.

2. No Minimum Order Quantity

Many UV DTF printing companies offer no minimum order quantities, making it easier for small businesses and startups to access high-quality printing without large upfront investments. This flexibility allows brands to test designs before committing to larger runs.

3. Full-Color Printing

With the potential for full-color printing, UV DTF techniques can reproduce complex images and gradients that traditional screen printing might struggle with. This capability opens new avenues for artistic expression.

4. Easy Application

The transfer process for UV DTF prints is user-friendly. Once printed onto the film, the designs can be easily heat-pressed onto the desired substrate, ensuring consistent quality and results.

Applications of UV DTF Custom Printing

Textiles: UV DTF printing is ideal for custom apparel, bags, and home textiles.

Promotional Items: Businesses can create branded merchandise, including caps, mugs, and keychains.

Decorative Items: UV DTF is perfect for creating wall art, home décor, and gift items.

Industrial and Commercial Uses: Labels, tags, and signage can be produced with high durability to withstand environmental factors.

The UV DTF Printing Process Explained

Understanding the UV DTF printing process can help you appreciate its efficiency and effectiveness. Here’s a step-by-step overview:

1. Design Creation

The process starts with creating a digital design file, which can be done using graphic design software. The more refined the design, the better the final print will be.

2. Printing

The design is printed onto a specialized film using UV-cured inks. The printer uses a UV light source to cure the inks as they are printed, resulting in instant drying and allowing for high-resolution output.

3. Film Application

Once printed, the film is cut to size, and any excess material is removed. The transfer film now contains your custom design, ready for application.

4. Heat Transfer

The final step involves heat pressing the film onto the chosen substrate. The heat activates the adhesive in the ink, bonding the print to the surface permanently.

Choosing the Right UV DTF Printer

Selecting the perfect UV DTF printer is crucial to achieving quality results. Here are some factors to consider:

Printing Speed: Analyze how fast the printer can produce outputs, particularly if you require large volumes regularly.

Print Quality: Look for printers that offer high DPI (dots per inch) capabilities to ensure sharpness and detail.

Size and Dimensions: Consider what sizes of prints you need, as some printers may have limitations on the width or length of material.

Cost: Evaluate your budget, including the initial purchase price and ongoing supplies like inks and films.

Support and Warranty: It's vital to choose a reputable manufacturer that offers support and warranty coverage to protect your investment.

If you're interested in exploring high-quality UV DTF printers, explore our high-quality UV-DTF printers here.

Conclusion

UV DTF custom printing stands out as a pioneering technology that harmonizes durability, vibrancy, and versatility. This innovative method is an excellent solution for a variety of applications ranging from textiles to promotional products. Businesses that embrace UV DTF printing can greatly enhance their branding, reaching customers with high-quality, customizable items that stand the test of time. As the demand for personalized, durable products continues to grow, investing in UV DTF technology can provide a competitive edge and open new revenue streams.

FAQ

What materials can UV DTF printing be used on?

UV DTF printing is incredibly versatile and can be used on various materials, including textiles, plastics, metals, wood, glass, and more. This makes it suitable for a wide range of applications.

How durable are UV DTF prints?

UV DTF prints are highly durable, thanks to the UV curing process. They are resistant to scratches, fading, and water, ensuring that your designs can withstand wear and maintain their appearance over time.

Is UV DTF printing eco-friendly?

Yes, UV DTF printing is considered more eco-friendly than traditional printing methods. UV inks produce fewer volatile organic compounds (VOCs), contributing to a reduced environmental impact.

What is the typical turnaround time for UV DTF printing?

Due to the instant curing process of UV inks, UV DTF printing generally offers faster turnaround times compared to other printing methods. Exact times can vary based on the complexity of the order and materials used.

Is there a minimum order quantity for UV DTF printing?

Many UV DTF printers offer the flexibility of no minimum order quantity, which is beneficial for small businesses or prototyping designs without committing to larger runs.