Introduction

In the world of UV printing, preparing your artwork properly is crucial to achieving high-quality results. With its ability to print on a wide range of materials and its quick curing process, UV printing has become a favorite among graphic designers and print shops alike. However, many artists and designers face common challenges when preparing their artwork for UV prints, which can lead to disappointment and wasted resources. In this post, we will explore these common mistakes and provide you with the tips needed to ensure your artwork is print-ready.

Understanding UV Printing

Before we dive into the common mistakes made during artwork preparation, it's essential to understand what UV printing is. UV (Ultraviolet) printing is a digital printing technology that uses ultraviolet light to cure or dry the ink as it is printed. This method allows for vibrant colors and sharp details on a variety of surfaces, including plastic, metal, wood, and glass.

However, the uniqueness of this printing technique comes with its own set of challenges when it comes to artwork preparation. Let's delve into the common pitfalls to avoid.

Common Artwork Mistakes in UV Print Prep

1. Incorrect Color Profiles

One of the most common mistakes is using the wrong color profile. UV printing typically uses CMYK (Cyan, Magenta, Yellow, Black) color mode for accurate color representation.

Tip: Always convert your artwork to CMYK mode before sending it to print. This will help prevent unexpected color shifts and ensure that the printed colors match your design intentions.

2. Low Resolution Images

Using low-resolution images can lead to pixelation and a lack of detail in the final print. UV printing allows for high-quality reproductions, so it’s crucial to provide images that are at least 300 DPI (dots per inch).

Tip: Check the resolution of your images and ensure they are set to at least 300 DPI for the best results. If you're scaling up an image, be careful, as enlarging can compromise quality.

3. Inadequate Bleed and Margins

Bleed refers to the area of the artwork that extends beyond the actual print size, ensuring that there are no white edges when the print is trimmed. Failing to include sufficient bleed can result in unsightly white borders.

Tip: Include at least 0.125 inches of bleed on all sides of your design. This is especially important for print products like business cards, posters, and packaging.

4. Not Considering Material Compatibility

Each substrate behaves differently during the printing process. Not taking the material's properties into account can lead to adhesion issues and color discrepancies.

Tip: Always consult with your printer about the materials you plan to use. Ensure your artwork is tailored for the specific substrate, taking into consideration factors like finish, texture, and absorbency.

5. Overlooking Safe Zones

Safe zones are crucial elements of print design. Important text or graphic elements too close to the edge of the design may get cut off during the trimming process.

Tip: Keep all essential elements at least 0.25 inches away from the trim edge. This ensures that your design remains intact after cutting.

6. Text Size and Fonts

Using very small fonts can result in them becoming illegible after printing. Additionally, not converting text to outlines can lead to missing fonts and formatting issues.

Tip: Use a minimum font size of 6 points and be sure to convert all text to outlines or rasterize it to keep your design intact before printing.

7. Not Proofing Artwork

Skipping the proofing stage can lead to significant mistakes going unnoticed until it’s too late. This might range from color mismatches to text errors that could tarnish the final product.

Tip: Always request a proof before final printing. Digital proofs allow you to catch any potential errors and make necessary adjustments.

The Importance of Communication with Your Printer

Establishing a good relationship with your printing service can significantly enhance your printing project’s success. Communication is key in sharing your expectations, and they can provide you with invaluable insights based on their expertise.

Tip: Don't hesitate to ask questions about the printing process or equipment. They can guide you on best practices tailored specifically to their machines and materials.

Conclusion

In summary, avoiding these common artwork mistakes in UV print preparation can greatly improve the quality of your final prints and save you time and resources. By ensuring correct color profiles, using high-resolution images, including adequate bleed and safe zones, and maintaining open communication with your printer, you can produce stunning prints that meet your expectations.

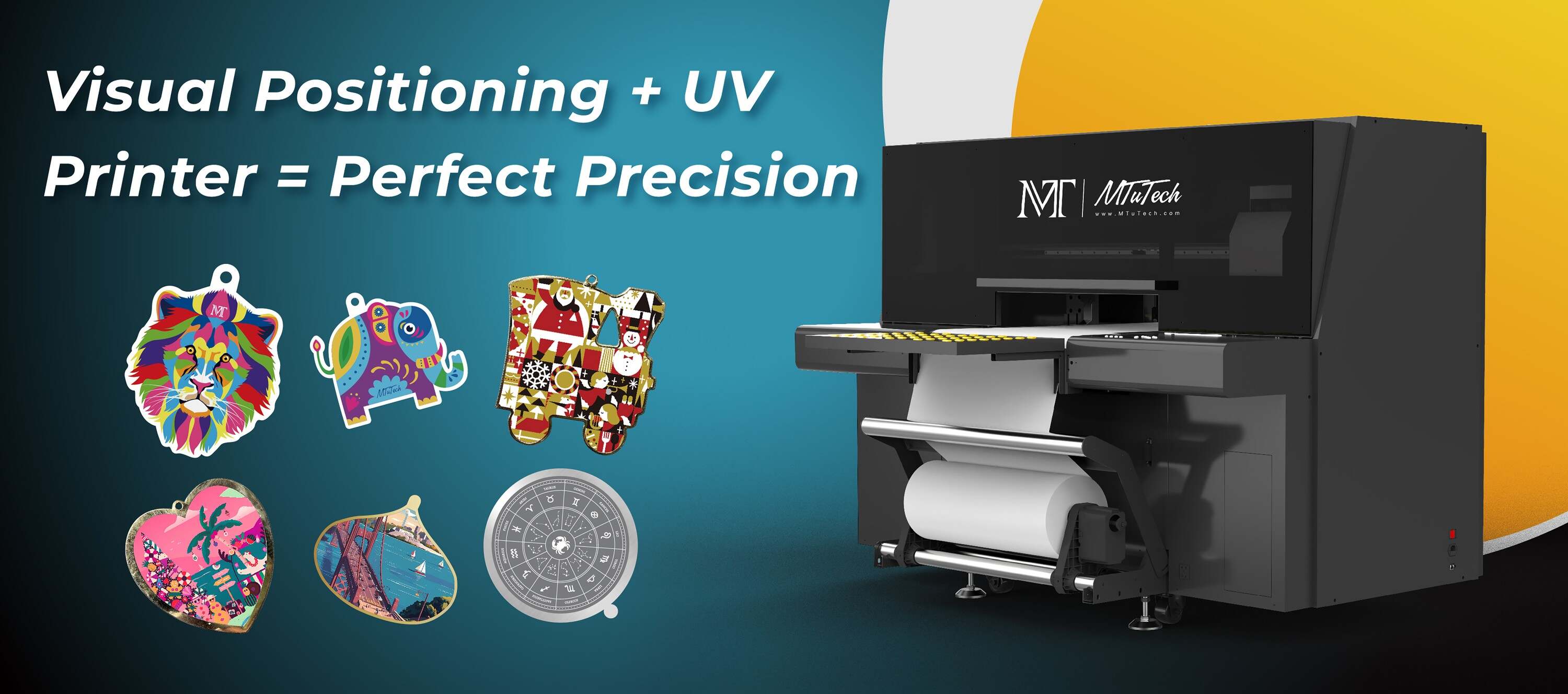

For anyone looking to dive deeper into the world of UV printing, check out our resources to help you navigate this exciting and versatile medium. Explore our high-quality UV printers here to get started on the right path.

FAQ

What is the difference between CMYK and RGB?

CMYK is a color model used in color printing, based on cyan, magenta, yellow, and black inks. RGB, on the other hand, is used for digital screens and is based on red, green, and blue light. Using the correct model for printing is essential to avoid color discrepancies.

Why is bleed important in print design?

Bleed is vital in print design because it ensures that your artwork extends beyond the trim edges. This prevents any unexpected white borders from appearing in the final print, thus maintaining a professional appearance.

How can I check the resolution of my image?

You can check the resolution of your image in most graphic design software by navigating to the image properties or image size settings. Make sure the DPI is set to at least 300 for high-quality printing.

Can I use any font for my print design?

While you can use any font for your design, it’s essential to ensure that the font is legible in print. Additionally, convert text to outlines or rasterize it to avoid missing fonts during printing.