Introduction

Introduction

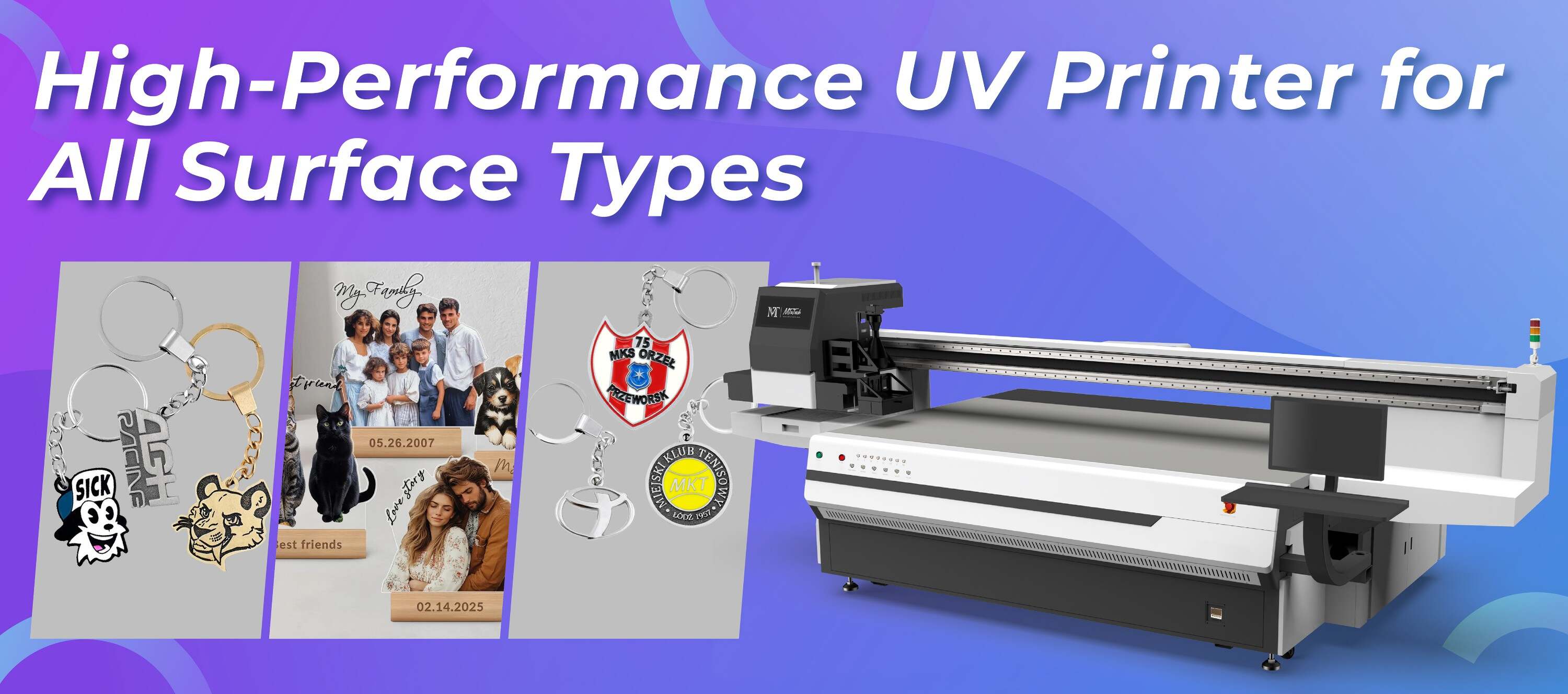

One of the biggest advantages of UV printing is its versatility. Unlike traditional methods, UV printers can handle a wide range of substrates — from rigid to flexible, transparent to textured. Whether you’re printing promotional products, signage, or customized gifts, knowing which materials work best can save time, money, and frustration. Here's your go-to guide on the best substrates for UV printing.

What Makes a Substrate UV-Printable?

For a material to work well with a UV printer, it should:

- Be non-porous or coated for ink adhesion

- Withstand UV lamp exposure without warping or discoloration

- Have a smooth, clean surface for detailed prints

- Remain flat during the printing process

Top Rigid Substrates for UV Printing

- Acrylic: Ideal for signage, awards, and décor

- Metal (Aluminum, Steel, Brass): Durable and sleek for tags, panels, and signage

- Glass: Premium choice for art and architectural applications

- Wood (MDF, Plywood): Great for personalized items and rustic branding

- PVC and Foam Boards: Lightweight and cost-effective for indoor displays

Top Flexible Substrates for UV Printing

- Vinyl and Banners: Perfect for outdoor graphics and roll-to-roll printing

- Leather and Faux Leather: Used in fashion, gifting, and luxury branding

- PET and Polycarbonate Films: Durable and clear, often used in industrial labels

- Paperboard and Cardstock: Excellent for packaging and custom promotional materials

Specialty Substrates That Work with UV Printing

- Ceramics: Tiles and mugs become custom art pieces

- Canvas: Used in fine art and high-end wall prints

- Rubber and Silicone (with primer): Great for phone covers and promotional products

- Stone and Slate: Often used in personalized gifts and home décor

Tips for Printing on Challenging Materials

- Use adhesion promoters for non-absorbent materials like glass and metal

- Maintain a dust-free environment to avoid specks under the print

- Adjust lamp intensity and ink layer thickness based on material thickness and color

- Test prints before running large batches

Conclusion

Choosing the right substrate is half the battle in UV printing. By understanding how different materials interact with UV inks and light curing, you can expand your product offerings, improve quality, and attract more clients.

Need a printer that works flawlessly across all these materials? Explore our hybrid UV printer that’s compatible with a wide variety of rigid and flexible substrates.