Introduction

In today’s fast-paced printing industry, the utilization of UV ink has become increasingly prevalent. Known for its quick drying and durable properties, UV ink offers various benefits for both printers and end-users. However, the importance of UV ink certification and safety standards cannot be overstated. This blog will delve into the significance of these certifications and the safety standards that govern the use of UV inks, ensuring that they are safe for both operators and consumers.

Understanding UV Ink

Ultraviolet (UV) ink refers to a type of ink that dries quickly when exposed to UV light. The use of this ink is particularly common in various printing applications, including signage, packaging, and promotional products. UV inks come with several advantages:

Rapid curing: UV inks cure instantly when exposed to ultraviolet light, allowing for faster production times.

Vibrant colors: The chemical composition of UV inks produces bright and vivid colors that are resistant to fading.

Eco-friendly options: Many UV inks are formulated with environmentally friendly ingredients, reducing their environmental impact.

The Need for Certification

While UV ink presents many benefits, the absence of adequate safety protocols and standards can lead to serious health and environmental issues. This is where certification comes into play. UV ink certification serves several crucial purposes:

1. Ensuring Product Safety

Certification signifies that the UV ink has gone through rigorous testing and meets regulatory safety standards. This assures users that the inks are safe for their intended applications, including food packaging or children's products.

2. Maintaining Quality Consistency

Certified inks are produced under strict quality control measures, ensuring that every batch meets consistent performance standards. This consistency is vital for printers who rely on quality results for their clients.

3. Building Consumer Trust

Consumers are becoming increasingly aware of the products they use. Certifications can significantly impact purchasing decisions, as they indicate transparency and reliability in the manufacturing process.

Safety Standards in UV Ink Production

Various safety standards guide the production and use of UV inks. Adhering to these standards ensures a higher level of safety for both manufacturers and end-users.

1. ANSI and ISO Standards

The American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) provide frameworks for evaluating the safety and performance of UV inks. Compliance with these standards ensures adherence to quality and safety measures.

2. REACH Compliance

In Europe, the Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) regulation requires that all chemicals used in products, including inks, are registered and assessed for safety. This compliance is essential to minimize exposure to hazardous substances.

3. ASTM Standards

The American Society for Testing and Materials (ASTM) develops standards to ensure the reliability and safety of materials, including UV inks. Adhering to ASTM standards can mitigate risks and enhance the overall quality of printed materials.

Benefits of UV Ink Certification

Certifications and safety standards have several benefits beyond mere compliance. Here are some key advantages that demonstrate the importance of UV ink certification:

Enhanced Safety: As certification ensures compliance with safety regulations, users can be confident in the safety of the inks they are using for their projects.

Environmental Protection: Certified inks often incorporate eco-friendly materials that reduce the environmental impact of printing processes.

Improved Market Access: Many markets require specific certifications before allowing products to be sold. Having certified UV inks can open doors to new opportunities and customer bases.

Competitive Advantage: Businesses using certified inks can differentiate themselves from competitors, portraying a commitment to quality and safety that attracts discerning customers.

Common Misconceptions about UV Inks

Despite the advantages and safety standards associated with UV inks, there are common misconceptions that can mislead businesses and consumers alike. Understanding these misconceptions is crucial for making informed decisions.

1. UV Inks Are Unregulated

Many believe that UV inks are unregulated due to their relatively recent popularity. However, as discussed, there are several certifications and safety standards that govern their production and use.

2. All UV Inks Are Identical

Another misconception is that all UV inks offer the same quality and safety. Not all inks are created equal, and it is vital to select certified options that have been rigorously tested.

3. UV Ink Is Hazardous

While some might think that UV ink poses a health risk, when produced under strict safety standards, certified UV inks are largely safe for both users and the environment.

Choosing Certified UV Inks

Selecting certified UV inks for your printing needs involves some key considerations:

Check for Certifications: Always look for products that display relevant safety certifications.

Research Manufacturers: Choose manufacturers with a solid reputation for producing high-quality, safe inks.

Consult with Experts: If unsure, consult with industry experts or organizations that specialize in printing technology.

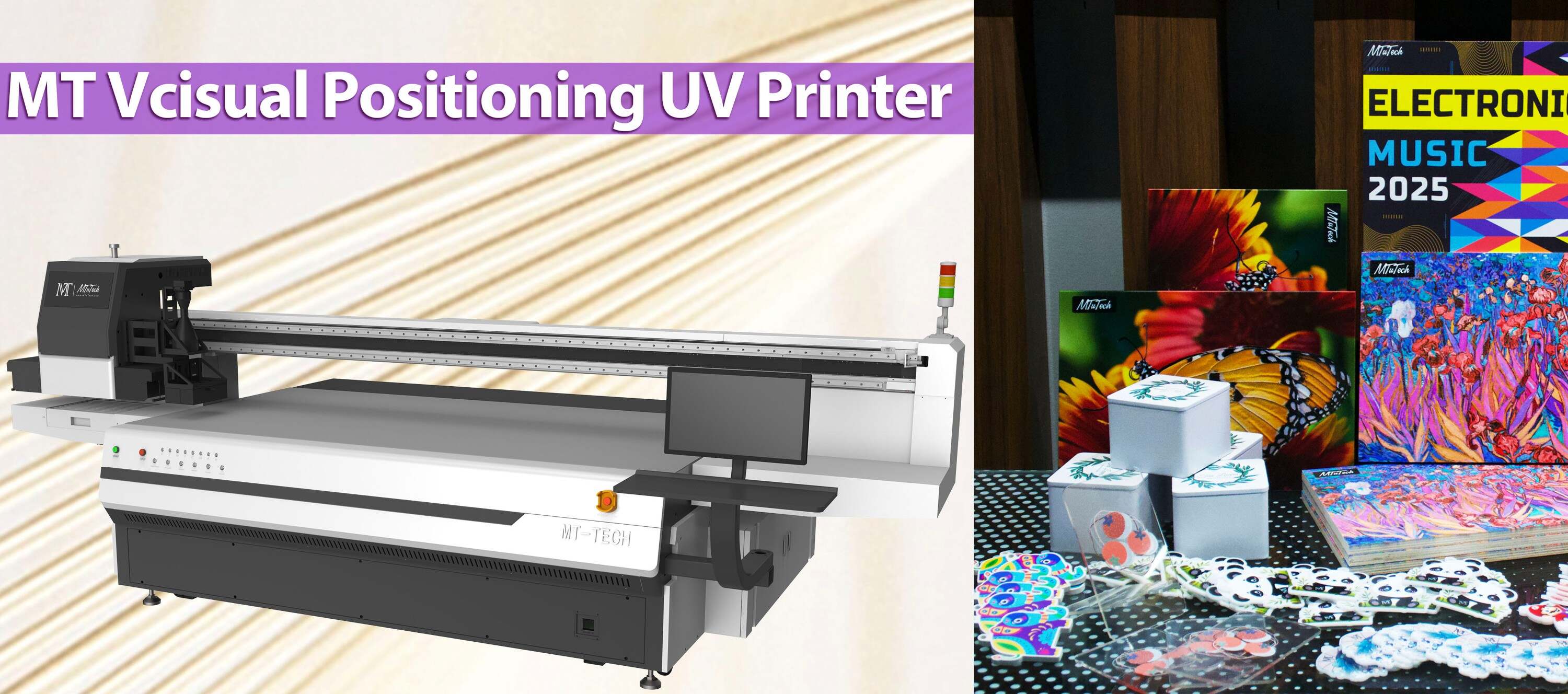

For those seeking high-quality UV printers designed to work seamlessly with certified inks, explore our high-quality UV printers here. Ensuring you have the right equipment is just as important as using quality inks.

Conclusion

UV ink certification and adherence to safety standards are vital components in the printing industry. The benefits of using certified inks extend beyond mere compliance; they enhance safety, improve quality, and support environmental sustainability. As the demand for UV ink continues to grow, the importance of understanding and leveraging certifications will play a crucial role in ensuring safe and effective printing solutions. By choosing certified UV inks, businesses can align themselves with current safety regulations and consumer expectations while also standing out in a competitive market.

FAQ

What are UV inks?

UV inks are printing inks that dry quickly when exposed to ultraviolet light. They are known for producing vibrant colors and allowing for faster production times in various printing applications.

Why is certification important for UV inks?

Certification ensures that UV inks have passed safety testing and meet regulatory standards, guaranteeing their safety for specific uses, such as in food packaging and children's products.

What safety standards apply to UV inks?

Several safety standards apply to UV inks, including ANSI and ISO standards, REACH compliance in Europe, and ASTM standards, which collectively ensure safety, quality, and environmental protection.

Are all UV inks safe to use?

Not all UV inks are safe. It is essential to choose inks that have obtained the necessary certifications to ensure their safety and compliance with industry standards.

How can I choose certified UV inks for my projects?

To choose certified UV inks, check for visible certifications, research reputable manufacturers, and consult with industry experts to ensure you are selecting high-quality inks that meet safety standards.