Introduction

In the world of printing, color consistency can make or break a product's appeal. Consumers today are exposed to a barrage of visually striking materials, making the need for high-quality, vibrant colors in printed products paramount. This is particularly true for UV (ultraviolet) printed items, where the technology used directly impacts not only the vibrancy but also the durability of the colors. Understanding the value of color consistency in UV printed products cannot be overstated, as it influences brand identity, customer satisfaction, and ultimately sales.

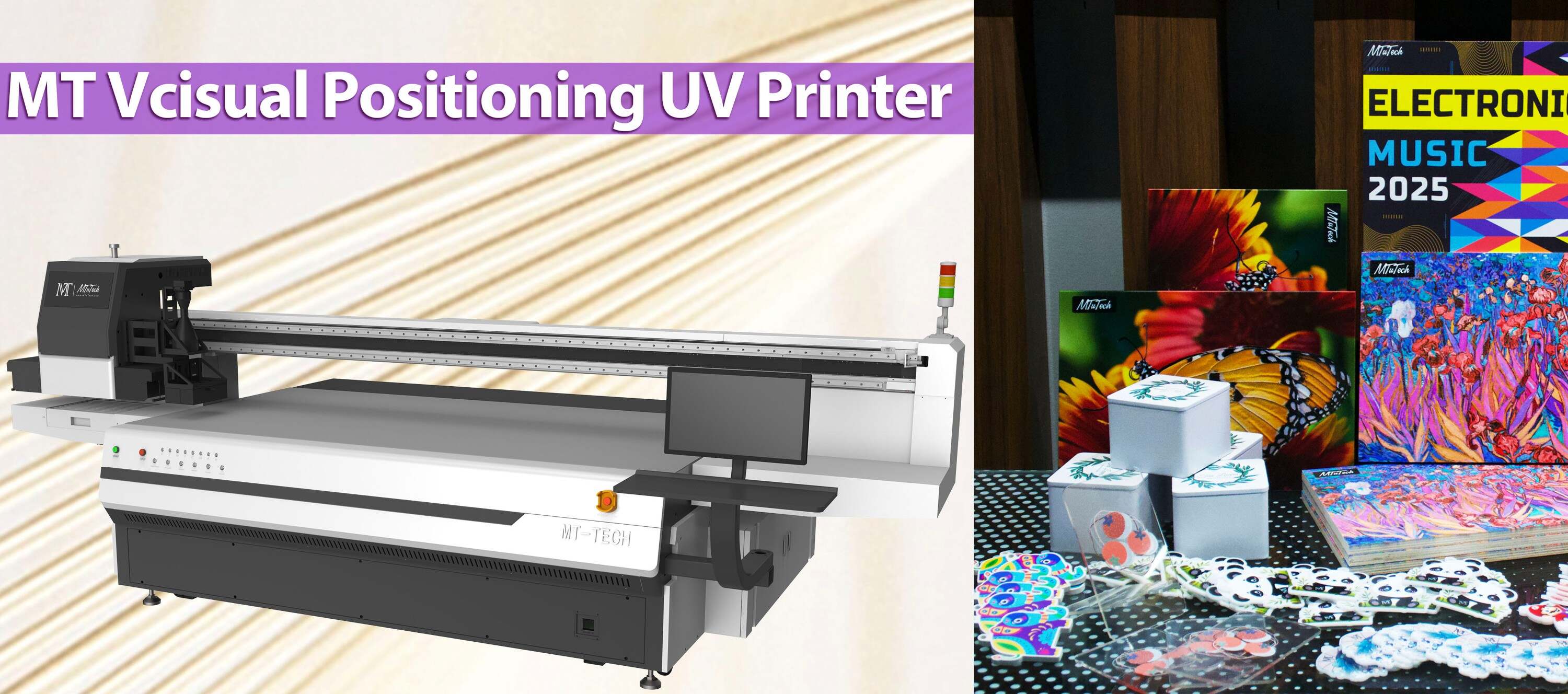

What is UV Printing?

UV printing is a modern printing technique that uses ultraviolet light to cure or dry the ink as it's printed. This process allows for faster production times, enhances the vibrancy of colors, and provides a durable finish that stands up to various environmental factors. It's especially popular for materials such as plastics, glass, and metal, which can often present challenges for traditional printing methods.

Benefits of Color Consistency in UV Printed Products

1. Brand Identity

Your brand's visual identity is crucial in establishing customer recognition and loyalty. Color is one of the most immediate triggers of brand association. When printed materials consistently reflect your brand colors—across packaging, marketing materials, and product labels—you create a cohesive brand image. This reliability builds trust among consumers.

2. Customer Satisfaction

Consumers expect that the colors they see on a product online or in-store reflect what they receive. Any discrepancies can lead to confusion or disappointment, eroding customer trust. Color consistency ensures that customers are satisfied with what they purchase, reducing the chances of returns and negative reviews.

3. Enhanced Visibility

Vibrant, consistent colors can make products stand out in a densely populated marketplace. Whether it's the bright hue of a promotional flyer or the rich coloration of a custom gift item, color plays a significant role in attracting consumer attention. UV printing ensures colors are rich and consistent from the first print to the last, which is vital for marketing campaigns.

4. Improved Quality Perception

Consumers often associate the quality of a product with its visual presentation. Products that exhibit consistent, vibrant colors convey a sense of quality and professionalism. On the other hand, inconsistent colors can imply poor manufacturing practices, which can deter potential buyers from making a purchase.

Features of UV Printing that Ensure Color Consistency

1. Instant Drying

The UV curing process allows the ink to dry almost immediately after being applied. This immediate transformation locks in the color quality and minimizes the risk of smudging or running, ensuring that what you see is what you get.

2. Wide Color Gamut

UV printers often utilize advanced ink sets that deliver a broader color gamut compared to traditional methods. This capability allows for more vibrant colors and finer details, making it easier to achieve color accuracy across different products.

3. Substrate Versatility

One of the unique aspects of UV printing is its adaptability to various surfaces, from steep plastics to textured materials. Each substrate may react differently to color, but high-quality UV printers come equipped with settings and technology to maintain color consistency across diverse materials.

4. Consistent Ink Delivery Systems

Modern UV printers often feature sophisticated ink delivery systems that reduce color variations. By controlling the micro-dosing of ink and employing advanced calibration techniques, these systems ensure that colors remain consistent, even across large runs of prints.

Best Practices for Maintaining Color Consistency

Conduct Regular Calibration: Regularly calibrate your UV printer to maintain its color output precision.

Use Quality Inks: Select high-quality inks that are designed to work with your specific UV printer.

Store Materials Properly: Environmental factors such as humidity and temperature can affect ink and substrate quality, so be mindful of how you store printing materials.

Use Color Profiles: Implementing ICC color profiles can help ensure that the colors represent accurately throughout various devices from design to print.

Consistent Work Environment: Maintain a stable working environment to reduce the risk of color inconsistency caused by fluctuating conditions.

Conclusion

The value of color consistency in UV printed products is significant, influencing everything from brand identity to customer satisfaction. As consumers continue to demand high-quality, visually appealing products, businesses must recognize the importance of investing in technologies and practices that ensure color accuracy. Utilizing reliable UV printers not only enhances product quality but also fosters greater loyalty and trust among customers. To stay competitive in a visually-driven economy, businesses should consider the full spectrum of benefits that color consistency can offer.

For those looking to elevate their printing capabilities, explore our high-quality UV printers here. With the right tools, achieving vibrant color consistency is more accessible than ever.

FAQ

What is the difference between UV printing and traditional printing?

UV printing uses ultraviolet light to cure ink as soon as it's applied, resulting in vibrant colors and faster drying times. Traditional printing methods may use solvent-based inks that can take longer to dry and may not achieve the same rich color vibrancy.

Can color consistency be maintained across different materials?

Yes, one of the advantages of UV printing is its adaptability to various substrates. High-quality UV printers utilize advanced technology to ensure that colors remain consistent, even when printed on different materials.

How often should printers be calibrated for optimal color consistency?

Calibration should be performed regularly, typically every few weeks or after significant changes in environmental conditions. It’s also wise to calibrate the printer after a major ink change or before beginning a large print run.

What should I do if I notice color inconsistencies in my UV printed products?

If you notice inconsistencies, it may be time to recalibrate your printer, check ink quality, or inspect your printing environment. Regular maintenance and testing can help mitigate issues before they affect larger batches.