Introduction

In today’s fast-paced business landscape, zero-inventory businesses have gained traction as a sustainable and efficient way to operate. By leveraging just-in-time manufacturing and on-demand production, companies can significantly reduce overhead costs associated with storage and inventory management. One pivotal technology facilitating this model is UV printing. This blog post delves into the role of UV printers in zero-inventory businesses, highlighting their advantages, features, and practical applications.

Understanding UV Printing

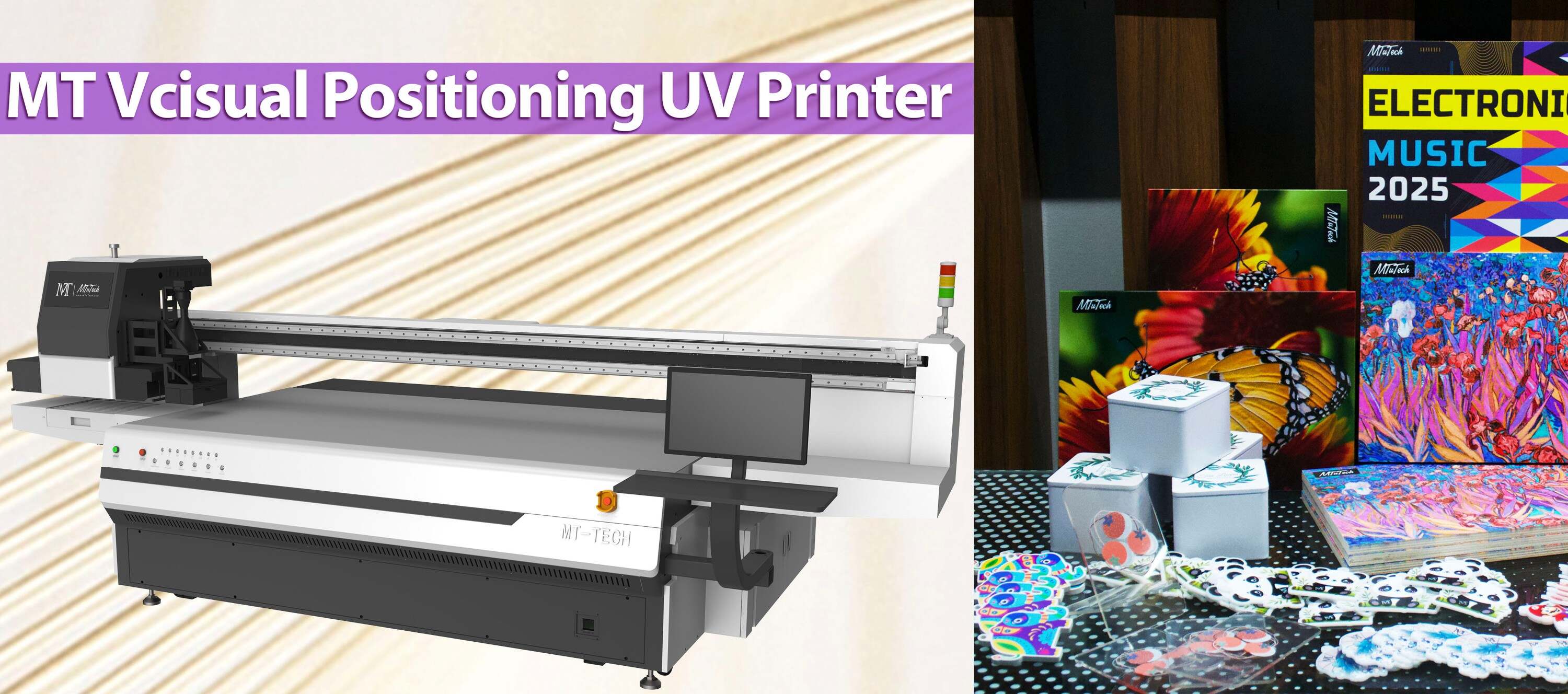

What is UV Printing?

UV printing is a digital printing technology that uses ultraviolet (UV) light to cure or dry the ink as it is printed. Unlike traditional printing methods that rely on solvents and drying time, UV printing allows for instant drying and provides vibrant colors and high levels of detail. This method can be used on a wide range of substrates, including paper, plastic, metal, and glass, making it a versatile option for many businesses.

How UV Printers Work

In UV printing, specially formulated inks are exposed to UV light upon application, resulting in rapid polymerization. The process follows these steps:

The printer applies UV ink to the chosen substrate.

As the ink is applied, it passes under UV lamps that cure it instantly.

This creates a durable, high-quality finish that is resistant to scratches, water, and fading.

The Role of UV Printers in Zero-Inventory Businesses

Zero-inventory businesses embrace on-demand production, allowing them to respond to customer needs without the burden of excess stock. This is where UV printers become a game changer. Here’s how they fit into this model:

1. Customization and Personalization

Consumers today expect personalized products. UV printers can create custom designs at a high quality without setup costs associated with traditional printing methods.

Fast Turnaround: With UV printing technology, businesses can quickly produce custom items as orders come in.

Variety of Materials: Businesses can print on different substrates, which opens up potential for varied products, from promotional materials to unique gifts.

2. Reduced Waste and Costs

Zero-inventory businesses benefit from reduced waste generated from unsold goods. UV printing aligns perfectly with this philosophy:

Produce only what is needed, eliminating leftover stock.

Lower operating costs as there is no need for bulk printing or storage.

3. Flexibility in Product Offerings

UV printers allow businesses to pivot quickly in response to market trends or customer demands. This flexibility is crucial in maintaining a competitive edge.

Ability to change designs without incurring high costs.

Easy introduction of new products or limited editions.

4. High-Quality Output

The superior quality of UV printing means that businesses can deliver impressive final products. This is essential for brand image, especially for businesses that rely on visual appeal.

Sharp details and vivid colors that attract consumers.

Durable finish that stands the test of time.

Benefits of Using UV Printers

Leveraging UV printers in zero-inventory businesses provides a multitude of benefits:

1. Cost Efficiency

The initial investment in UV printers can be offset by the savings realized from reduced waste and the elimination of inventory holding costs. Because products are printed on demand, funds are not tied up in unused stock.

2. Environmental Impact

With less waste and a shift towards digital production, businesses using UV printing can reduce their environmental impact. The technology’s energy-efficient process and minimal use of solvents support sustainable practices.

3. Easy Maintenance and Operation

Modern UV printers are designed for easy use and maintenance, allowing businesses to maximize productivity without significant downtime.

4. Diverse Applications

UV printing can be applied in various niches such as:

Signage and displays

Packaging and labels

Promotional products

Unique gifts and merchandise

Challenges and Considerations

While UV printing offers many advantages, it is essential to consider some challenges:

1. Initial Investment

The upfront cost of UV printers can be higher than traditional printers. However, this should be viewed in the context of the long-term savings and revenue potential.

2. Skill Requirements

While UV printers are user-friendly, they do require a level of training to ensure optimal performance and quality. Investing in training can pay off significantly.

Conclusion

UV printers are revolutionizing the way zero-inventory businesses operate. By enabling on-demand production, these printers contribute to cost savings, reduced waste, and enhanced flexibility—traits that are indispensable in today’s market. For businesses looking to optimize their operations, investing in a UV printer is a forward-thinking move that aligns well with a zero-inventory model.

Whether you’re a startup or a well-established company, explore our high-quality UV printers here to find solutions that cater to your unique needs. Embrace the future of printing and take your business to new heights with UV technology.

FAQ

What types of businesses can benefit from UV printers?

Businesses in various sectors, including retail, promotional products, packaging, and signage, can greatly benefit from UV printers due to their versatility and high-quality output.

What materials can UV printers print on?

UV printers can print on a wide range of materials, including paper, plastic, wood, glass, metal, and more, making them suitable for multiple applications.

Are UV printers environmentally friendly?

Yes, UV printers are more environmentally friendly than traditional printers since they produce less waste, use fewer solvents, and consume less energy during operation.

How does UV printing compare to traditional printing methods?

UV printing offers faster production times, higher quality outputs, and greater flexibility for customization compared to traditional printing methods, where drying times can slow down production and limit design options.

Is training required to operate UV printers?

While UV printers are designed to be user-friendly, training is recommended to ensure quality performance and maintenance. Familiarity with the technology will enhance productivity and product quality.