Introduction

In an era where environmental sustainability is a priority, the printing industry is adapting and evolving. One of the most promising methods that have emerged is UV printing on recycled materials. This revolutionary printing process not only reduces waste but also showcases the potential for high-quality prints on materials that were once considered unusable. In this article, we will explore the feasibility of UV printing on recycled materials, the benefits it offers, and the results achieved through this innovative technique.

Understanding UV Printing

Ultraviolet (UV) printing is a form of digital printing that uses ultraviolet light to cure or dry the ink as it is printed. Unlike traditional methods, where inks are absorbed by the substrate, UV printing allows for the application of ink on virtually any surface, including plastics, metals, glass, and more. The ink dries instantly upon exposure to UV light, which results in vibrant colors and sharp details.

The Basics of Recycled Materials

Recycled materials refer to products that have been reprocessed to make them suitable for reuse. Common recycled materials in printing include:

Paper and cardboard

Plastics

Metals

Glass

Using these materials in printing can significantly reduce waste and lower environmental impact, making UV printing on recycled materials an appealing option for eco-conscious businesses and consumers.

Feasibility of UV Printing on Recycled Materials

Transitioning to UV printing on recycled materials presents several challenges and opportunities. Understanding its feasibility requires a closer look at key factors including substrate compatibility, ink adhesion, and environmental considerations.

1. Substrate Compatibility

The nature of recycled materials can vary significantly, affecting their compatibility with UV inks. Some recycled substrates, particularly those that are porous, may absorb the ink rather than allowing for a crisp finish. Therefore, evaluating the specific characteristics of the substrate is crucial.

However, advancements in UV printing technology have led to the development of specialized inks and coatings targeting various substrates, enhancing the chances of successful adhesion on recycled materials.

2. Ink Adhesion

One of the biggest concerns when printing on recycled materials is ink adhesion. Due to their varied surface properties, recycled substrates can sometimes lead to challenges in ensuring that the ink adheres properly. This is where proper surface preparation plays a critical role.

Cleaning: Removing any dirt or contaminants can significantly improve adhesion.

Priming: Applying a primer can create a more compatible surface for the ink.

UV Coatings: Using a UV coating can also enhance adhesion and durability.

3. Environmental Considerations

UV printing is considered environmentally friendly since it emits minimal volatile organic compounds (VOCs) compared to traditional printing methods. Additionally, utilizing recycled materials further decreases the carbon footprint. This combination not only supports sustainability but also meets the growing demand for eco-friendly products.

Benefits of UV Printing on Recycled Materials

The shift toward UV printing on recycled materials offers numerous benefits, both for businesses and the environment.

1. Eco-Friendly Approach

Leveraging recycled materials aligns with sustainability efforts and can significantly reduce the demand for virgin materials. It helps create a closed-loop system in the printing industry, minimizing waste and conserving natural resources.

2. High-Quality Results

UV printing technology provides high-resolution prints with vibrant colors and exceptional detail, often outpacing traditional methods. When optimized, prints on recycled materials can achieve comparable quality, opening avenues for creative and attractive packaging, promotional materials, and more.

3. Versatility

UV printing is versatile and can be applied to a wide range of shapes and sizes. This adaptability allows businesses to think creatively about their printed products, utilizing different recycled materials that can take innovative forms.

4. Quick Turnaround Time

Since UV inks cure instantly under UV light, the printing process itself is faster. This benefits businesses that require quick turnaround and short-run jobs, enabling them to meet customer demands effectively.

5. Reduced Waste

By utilizing recycled materials, businesses can significantly reduce their production waste. This has both economic and ecological advantages, as it lowers disposal costs and reinforces corporate responsibility regarding environmental stewardship.

Challenges of UV Printing on Recycled Materials

While the benefits are substantial, challenges remain that businesses must address when implementing UV printing on recycled materials.

1. Cost Considerations

Initial investments in UV printing technology and materials may be higher than traditional printing. However, as awareness and demand increase for sustainable products, many find this cost to be an investment in the future.

2. Acceptance by Consumers

While many consumers are increasingly eco-conscious, there can be skepticism regarding the quality and durability of products made from recycled materials. Education and marketing are key to instilling confidence in customers regarding the results they can expect.

3. Material Availability

The availability and consistency of recycled materials can be irregular, potentially affecting production timelines. Establishing reliable sources and maintaining relationships with suppliers can help mitigate these challenges.

Conclusion

UV printing on recycled materials is a feasible option that not only enhances the quality of printed products but also supports sustainability goals. The benefits range from high-quality results and versatility to significant ecological advantages. While challenges exist, innovations in UV printing technology continue to pave the way for more efficient and sustainable practices in the industry.

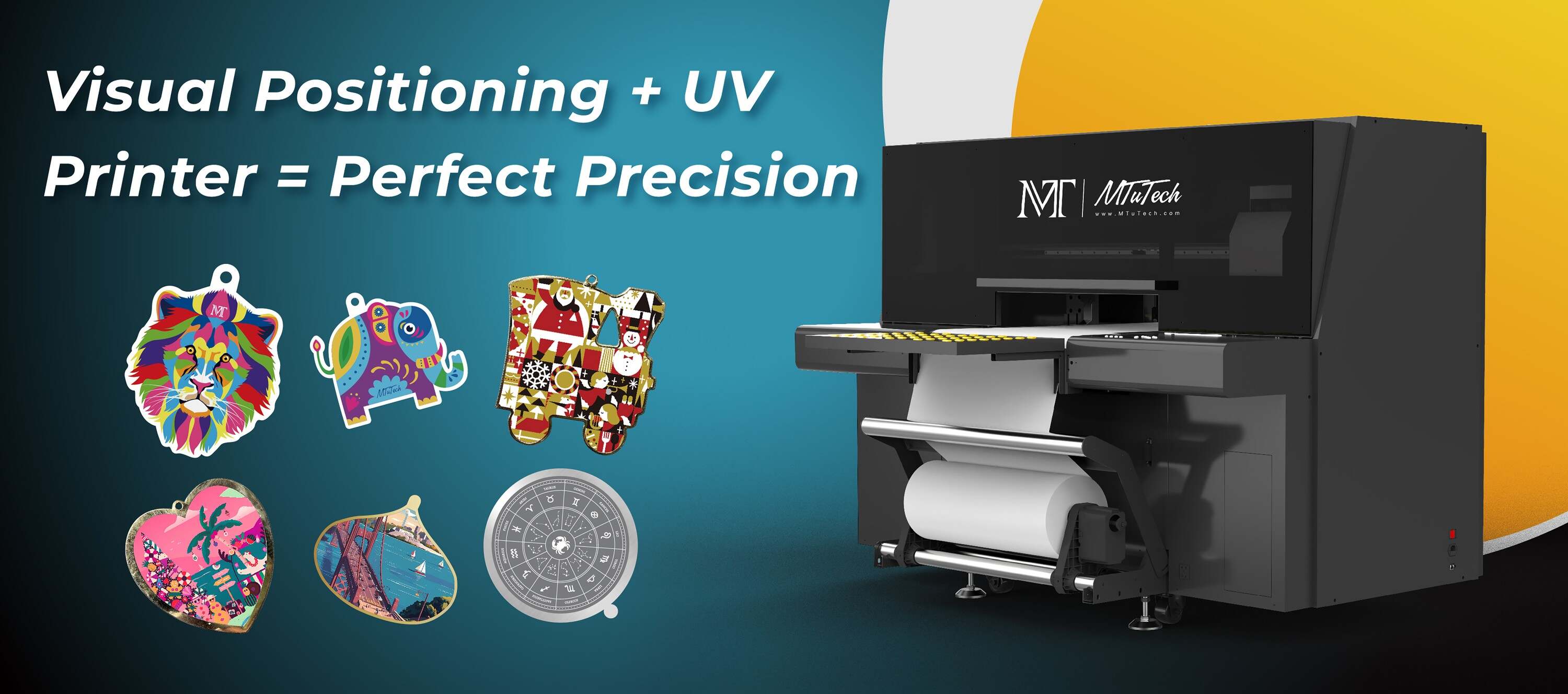

Businesses looking to embrace this eco-friendly approach should consider investing in high-quality UV printers that can work seamlessly with a variety of recycled materials. Explore our high-quality UV printers here to take the first step towards a sustainable printing future.

FAQ

What types of recycled materials can be used for UV printing?

UV printing can be performed on a variety of recycled materials including paper, cardboard, plastics, metals, and glass. The specific choice depends on the desired application and the compatibility of the material with UV inks.

Does UV printing on recycled materials offer the same quality as traditional methods?

Yes, when adequately prepared and with the right inks, UV printing on recycled materials can achieve high-quality results comparable to traditional printing methods. Innovations in technology have greatly improved print quality and color vibrancy on diverse substrates.

How does UV printing support sustainability?

UV printing reduces waste through the use of recycled materials and emits fewer volatile organic compounds (VOCs) than traditional methods, making it a more environmentally friendly option. By incorporating recycled materials, it helps conserve resources and lowers the overall carbon footprint of the printing process.

Are there any special preparation steps needed for recycled materials before UV printing?

Yes, preparing the substrate is essential. This may involve cleaning the surface, applying a primer, or using coatings designed to promote adhesion. Proper preparation can ensure better ink adherence and overall print quality.